In short, increasing pressure during hot press sintering primarily accelerates densification by promoting plastic deformation and breaking down surface oxide films on powder particles. This allows you to achieve a higher final density, often at a lower temperature or in a shorter amount of time compared to lower-pressure methods.

While higher pressure is a powerful tool for achieving density, it is not a simple solution. The core challenge lies in balancing the benefit of accelerated densification against the significant risk of creating non-uniform microstructures and anisotropic mechanical properties within the final part.

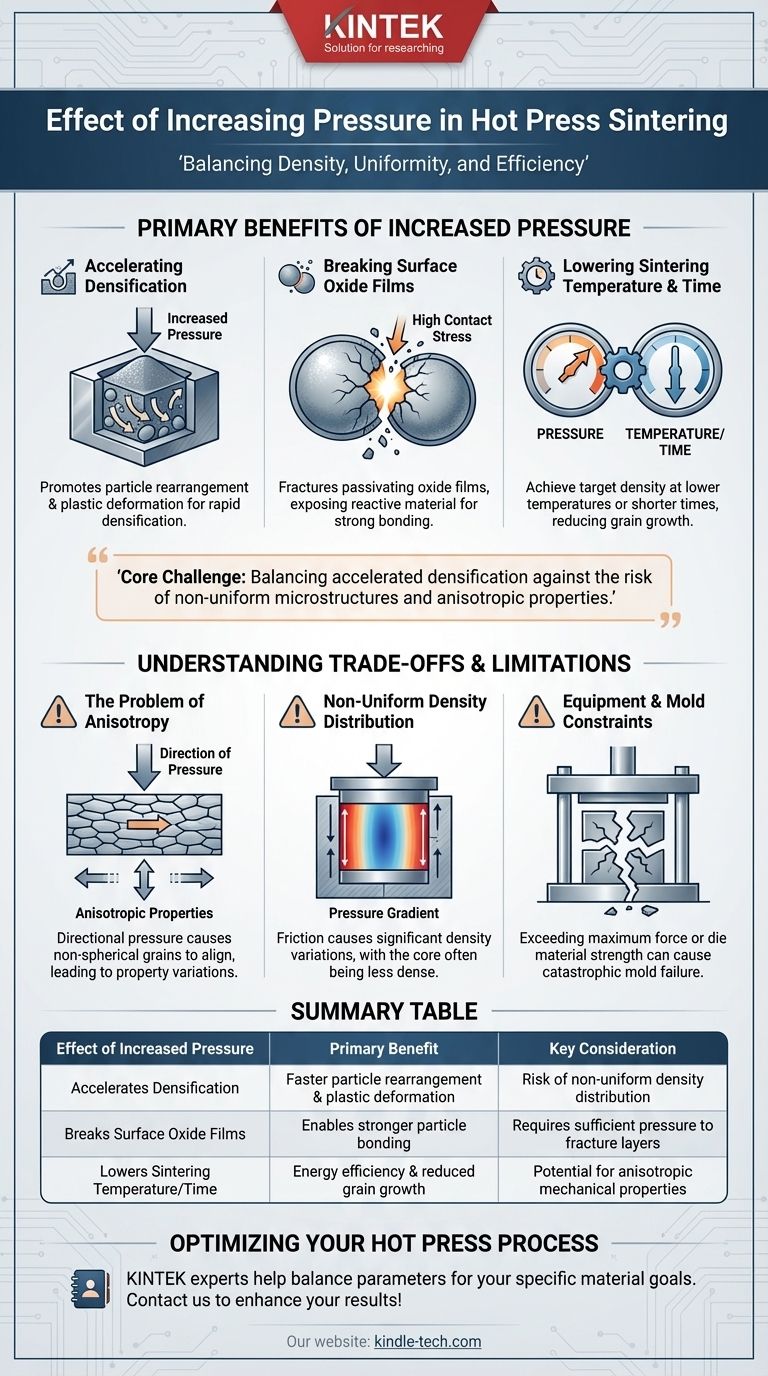

The Primary Benefits of Increased Pressure

Applying higher pressure directly influences the fundamental mechanisms that govern the sintering process. Understanding these effects is key to optimizing your parameters.

Accelerating Densification Mechanisms

At the beginning of the hot press cycle, densification is dominated by particle rearrangement and plastic deformation. Increased external pressure provides the driving force needed to make powder particles slide past one another and deform to fill void spaces, rapidly increasing the part's density.

Breaking Surface Oxide Films

Most metal or ceramic powders have a thin, passivating oxide film on their surface that inhibits direct bonding. The high contact stresses generated by increased pressure physically fracture these brittle layers, exposing fresh, highly reactive material that can then form strong metallurgical or ceramic bonds.

Lowering Sintering Temperature and Time

Pressure and temperature are coupled variables. By increasing the pressure, you can often achieve the target density at a significantly lower sintering temperature or reduce the required hold time. This can be crucial for preventing undesirable grain growth and preserving a fine-grained microstructure, which often leads to superior mechanical properties.

Understanding the Trade-offs and Limitations

Simply maximizing pressure is a common mistake that can introduce severe, often hidden, defects into your component. True process control requires acknowledging the inherent downsides.

The Problem of Anisotropy

Hot pressing typically applies force in a single direction (uniaxially). This can cause non-spherical or non-equiaxed powder grains to align themselves perpendicularly to the pressing direction. The result is anisotropy: the material will exhibit different mechanical and physical properties when measured parallel versus perpendicular to the direction of pressure.

Non-Uniform Density Distribution

Pressure is not transmitted perfectly through a powder compact. Friction between the powder and the die walls means the pressure is highest near the moving ram and decreases with depth into the part. This gradient can lead to significant variations in density, with the core of the component being less dense than the outer surfaces.

Equipment and Mold Constraints

There are hard physical limits to the pressure you can apply. The press itself has a maximum force rating, and more importantly, the die materials (often graphite) have limited compressive strength. Exceeding this limit will cause catastrophic failure of the mold, resulting in lost time and material.

Making the Right Choice for Your Goal

The optimal pressure is not a single value but depends entirely on the desired outcome for your specific component. Use these principles as your guide.

- If your primary focus is achieving maximum theoretical density: Use the highest pressure your mold and equipment can safely handle, but be prepared to characterize and potentially mitigate the resulting property anisotropy.

- If your primary focus is isotropic (uniform) properties: Favor a lower pressure combined with a carefully controlled temperature and time, or investigate advanced techniques like Hot Isostatic Pressing (HIP) if uniformity is non-negotiable.

- If your primary focus is process efficiency and throughput: Increasing pressure is an effective lever for shortening cycle times or lowering energy costs by reducing the peak sintering temperature.

Ultimately, pressure should be treated as a precise tool to manipulate material consolidation, not just a brute-force method for densification.

Summary Table:

| Effect of Increased Pressure | Primary Benefit | Key Consideration |

|---|---|---|

| Accelerates Densification | Faster particle rearrangement & plastic deformation | Risk of non-uniform density distribution |

| Breaks Surface Oxide Films | Enables stronger particle bonding | Requires sufficient pressure to fracture brittle layers |

| Lowers Sintering Temperature/Time | Energy efficiency & reduced grain growth | Potential for anisotropic mechanical properties |

Ready to optimize your hot press sintering process? The experts at KINTEK can help you balance pressure, temperature, and time to achieve your specific material goals—whether it's maximum density, isotropic properties, or faster cycle times. Contact us today to discuss how our specialized lab equipment and consumables can enhance your sintering results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process

- Why is precise temperature control necessary for SiC/Cu Vacuum Hot Pressing? Mastering the Cu9Si Interface Phase

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites