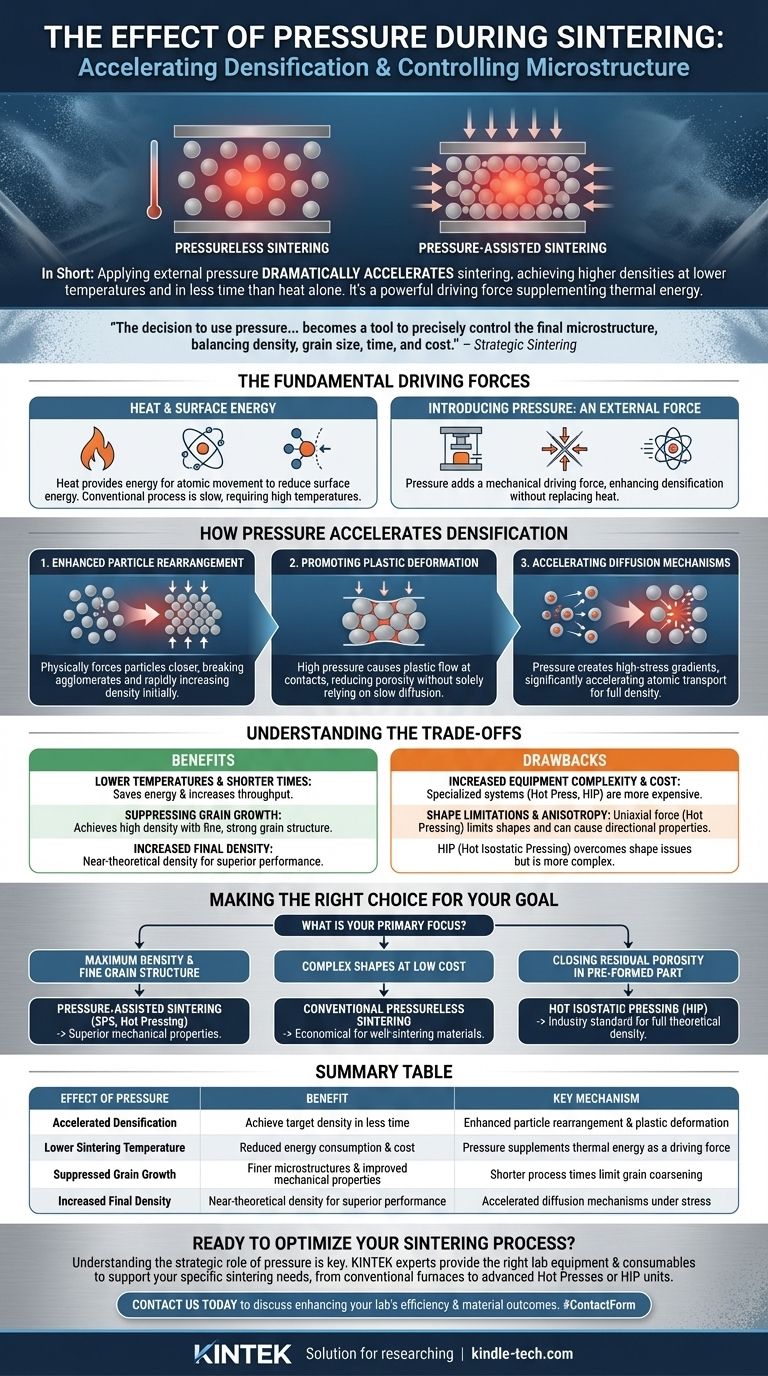

In short, applying external pressure during sintering dramatically accelerates the process of turning a powder into a dense, solid part. It acts as a powerful driving force that supplements the effects of heat, enabling you to achieve higher final densities at lower temperatures and in significantly less time than with pressureless methods.

The decision to use pressure in sintering is a strategic one. It moves beyond simply seeking density and becomes a tool to precisely control the final microstructure, balancing the relationship between density, grain size, processing time, and equipment cost.

The Fundamental Driving Forces of Sintering

Sintering is fundamentally about reducing the total surface energy of a system. A powder compact has a vast amount of surface area, which is energetically unfavorable. Heat provides the energy for atoms to move and bond together, reducing this surface area and creating a dense solid.

The Role of Temperature and Surface Energy

In conventional, pressureless sintering, temperature is the primary variable. It activates diffusion mechanisms, allowing atoms to move from particle contact points to fill the pores between them. This process is driven by the reduction of surface energy and is often slow, requiring high temperatures and long hold times.

Introducing Pressure: An External Driving Force

Applying external pressure introduces a powerful mechanical driving force for densification. This force does not replace the need for heat, but it works in concert with it, fundamentally changing the speed and outcome of the process.

How Pressure Accelerates Densification

Pressure assists in closing the gaps between powder particles through several key mechanisms, each dominant at different stages of sintering.

Enhanced Particle Rearrangement

In the initial stage, pressure physically forces particles closer together. This breaks down weakly bonded agglomerates and rearranges particles into a more tightly packed configuration, rapidly increasing the density before significant diffusion even begins.

Promoting Plastic Deformation

At elevated temperatures, the material's yield strength decreases. The applied pressure can be high enough to cause plastic deformation at the contact points between particles. This flattens the contacts, dramatically increasing the contact area and reducing porosity without relying solely on slower diffusion processes.

Accelerating Diffusion Mechanisms

Ultimately, achieving full density requires atomic transport. Pressure creates high-stress gradients at particle contacts, which significantly accelerates diffusion. Atoms are more inclined to move away from these high-stress areas and deposit into the low-stress pore regions, closing them much faster than temperature alone would allow.

Understanding the Trade-offs

While highly effective, pressure-assisted sintering is not a universal solution. The benefits must be weighed against practical and economic constraints.

The Benefit: Lower Temperatures and Shorter Times

The most significant advantage is process efficiency. By adding pressure, you can achieve a target density at a lower temperature or in a fraction of the time. This can save energy and increase throughput.

The Benefit: Suppressing Grain Growth

Because processing times and temperatures are reduced, particles have less opportunity to coarsen. This allows for the production of materials with very high density while maintaining an extremely fine, and therefore stronger, grain structure.

The Drawback: Increased Equipment Complexity and Cost

Pressure-assisted sintering requires specialized equipment like a hot press or a Hot Isostatic Press (HIP). These systems are significantly more expensive to purchase, operate, and maintain than a standard furnace used for pressureless sintering.

The Drawback: Shape Limitations and Anisotropy

Uniaxial methods like Hot Pressing apply force in one direction, which can lead to different properties along different axes (anisotropy) and is limited to relatively simple shapes. While Hot Isostatic Pressing (HIP) overcomes this by applying pressure uniformly, it is even more complex and costly.

Making the Right Choice for Your Goal

The choice between pressureless and pressure-assisted sintering depends entirely on your material requirements and economic constraints.

- If your primary focus is maximum density and a fine grain structure: Pressure-assisted sintering (like Spark Plasma Sintering or Hot Pressing) is the superior method for achieving peak mechanical properties.

- If your primary focus is producing complex shapes at a low cost: Conventional pressureless sintering remains the more practical and economical choice, especially for materials that sinter well without assistance.

- If your primary focus is closing residual porosity in a pre-formed part: Hot Isostatic Pressing (HIP) is the industry standard for post-processing to achieve full theoretical density.

Ultimately, understanding the role of pressure empowers you to select the most effective path to your desired material outcome.

Summary Table:

| Effect of Pressure | Benefit | Key Mechanism |

|---|---|---|

| Accelerated Densification | Achieve target density in less time | Enhanced particle rearrangement & plastic deformation |

| Lower Sintering Temperature | Reduced energy consumption & cost | Pressure supplements thermal energy as a driving force |

| Suppressed Grain Growth | Finer microstructures & improved mechanical properties | Shorter process times limit grain coarsening |

| Increased Final Density | Near-theoretical density for superior performance | Accelerated diffusion mechanisms under stress |

Ready to optimize your sintering process?

Understanding the strategic role of pressure is key to achieving your material goals, whether it's maximum density, a fine grain structure, or cost-effective production of complex shapes. The experts at KINTEK specialize in providing the right lab equipment and consumables to support your specific sintering needs.

We can help you select the ideal solution, from conventional furnaces to advanced pressure-assisted systems like Hot Presses or HIP units. Contact us today to discuss how our expertise can enhance your laboratory's efficiency and material outcomes.

#ContactForm to speak with a KINTEK specialist!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?

- What advantages does hot pressing sintering equipment provide for NASICON? Achieve 100% Dense Solid Electrolyte Plates