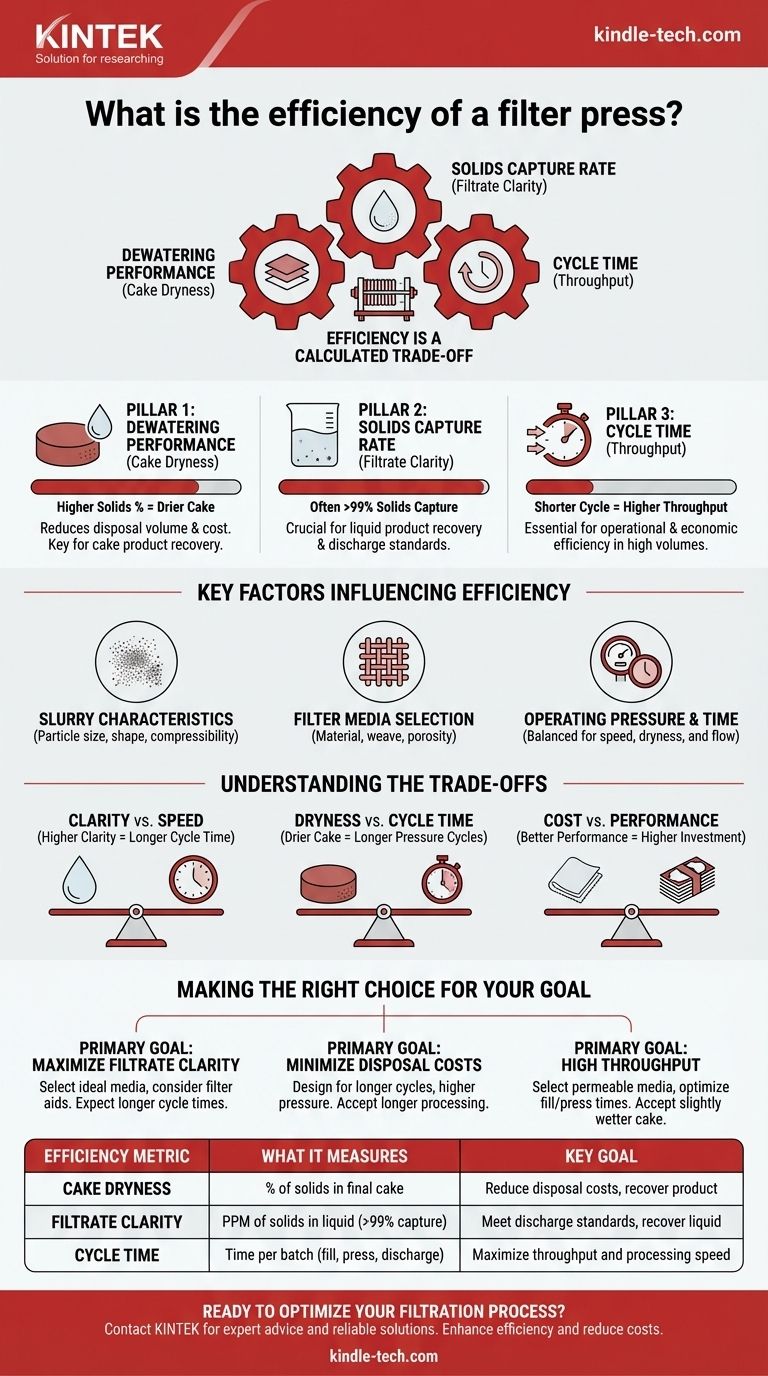

To be direct, a filter press does not have a single "efficiency" rating like an engine or a motor. Instead, its performance is a measure of three distinct outcomes: the dryness of the solid cake it produces, the clarity of the liquid it expels, and the speed at which it completes a cycle. The effectiveness of a press is defined by how well it achieves the specific goal you prioritize.

The core principle to understand is that filter press efficiency is not a single number but a calculated trade-off. Optimizing for one factor, such as cake dryness, will almost always impact another, like processing speed or filtrate clarity.

The Three Pillars of Filter Press Efficiency

To properly evaluate a filter press, you must analyze its performance across three key metrics. A successful operation purposefully balances these factors to meet a specific objective.

Pillar 1: Dewatering Performance (Cake Dryness)

This measures how effectively the press removes liquid from the solids. It is typically expressed as the percentage of solids by weight in the final filter cake.

A higher solids percentage means less moisture, resulting in a drier, more compact cake. This is often the most critical metric when the goal is to reduce disposal volume and cost, or when the cake is the desired final product.

Pillar 2: Solids Capture Rate (Filtrate Clarity)

This metric evaluates how well the press separates solids from the liquid. An efficient press produces a very clear liquid (the filtrate) with minimal suspended solids.

This is measured by parts per million (PPM) of solids in the filtrate or by turbidity. For applications where the liquid is the valuable product or needs to be discharged, achieving high filtrate clarity is the primary goal. A modern filter press can often achieve >99% solids capture.

Pillar 3: Cycle Time (Throughput)

This is the total time required to complete one full filtration batch: filling the press, applying pressure, discharging the cake, and preparing for the next cycle.

Shorter cycle times mean higher throughput, or the volume of slurry processed per day. This is a crucial measure of operational and economic efficiency, especially in high-volume industrial settings.

Key Factors Influencing Efficiency

The efficiency you can achieve is not determined by the press alone. It is a function of the entire system, including the material being processed and the operational parameters you set.

Slurry Characteristics

The nature of the input slurry is the single most important factor. Particle size, shape, concentration, and compressibility dictate how easily it can be dewatered. Fine, slimy, or gelatinous particles are notoriously difficult to filter and require longer cycle times.

Filter Media Selection

The filter cloth acts as the heart of the press. Its material, weave, and porosity must be matched to your slurry's particle size. A tighter weave improves filtrate clarity but can increase resistance to flow, slowing the cycle down.

Operating Pressure & Time

Higher feed pressure generally results in a drier cake and faster filtration, but only up to a point. Excessive pressure can blind the filter cloth or compact the cake so much that it becomes impermeable, halting progress. The duration of the pressure cycle is a direct trade-off with throughput.

Understanding the Trade-offs

You cannot maximize all three efficiency pillars simultaneously. Understanding these compromises is essential for successful operation.

Clarity vs. Speed

Achieving near-perfect filtrate clarity often requires a very fine filter medium. This creates higher resistance, which slows the flow of liquid through the press and significantly extends the overall cycle time, reducing throughput.

Dryness vs. Cycle Time

Pushing for the absolute driest cake possible requires longer press times under high pressure. Squeezing out the last few percentage points of moisture can dramatically increase the cycle time, which may not be economical if throughput is a priority.

Cost vs. Performance

High-performance filter cloths, automated systems for cake discharge, and higher-pressure systems all contribute to better performance but increase both capital investment and operational costs. The goal is to find the most cost-effective solution for your specific requirements.

Making the Right Choice for Your Goal

To optimize your filter press operation, you must first define your primary objective.

- If your primary focus is maximum filtrate clarity: Prioritize selecting the ideal filter media and consider using filter aids, accepting that this will likely lead to longer cycle times.

- If your primary focus is minimizing disposal costs (cake dryness): Design your process around longer pressure cycles and higher final pressures to achieve the maximum possible solids content.

- If your primary focus is high throughput (processing speed): Select a more permeable filter cloth and optimize for shorter fill and press times, even if it means accepting a slightly wetter cake.

Ultimately, an "efficient" filter press is one that is precisely tuned to achieve your most critical operational goal.

Summary Table:

| Efficiency Metric | What It Measures | Key Goal |

|---|---|---|

| Cake Dryness | % of solids in the final cake | Reduce disposal costs, recover product |

| Filtrate Clarity | PPM of solids in the liquid (often >99% capture) | Meet discharge standards, recover liquid |

| Cycle Time | Time per batch (fill, press, discharge) | Maximize throughput and processing speed |

Ready to optimize your filtration process?

An efficient filter press is one that is precisely tuned for your unique slurry and operational goals. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert advice and reliable filtration solutions.

Let our specialists help you select the right filter press and media to achieve the perfect balance of cake dryness, filtrate clarity, and processing speed for your application.

Contact us today for a personalized consultation and discover how we can enhance your lab's efficiency and reduce costs.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy