The efficiency of biomass pyrolysis is not a single number, but a complex balance of outputs that depends entirely on the process conditions and the desired end product. While the overall energy conversion efficiency—the ability to capture the original energy of the biomass in new forms—can be high (often 70-90%), this figure is misleading. The true effectiveness of the process is dictated by the trade-offs between energy inputs, capital costs, and the value of the resulting bio-oil, bio-char, and syngas.

The central takeaway is that while pyrolysis is an effective method for converting low-value biomass into energy-dense, storable products, its practical efficiency is often limited by high operational costs and the need for expensive post-processing of its outputs.

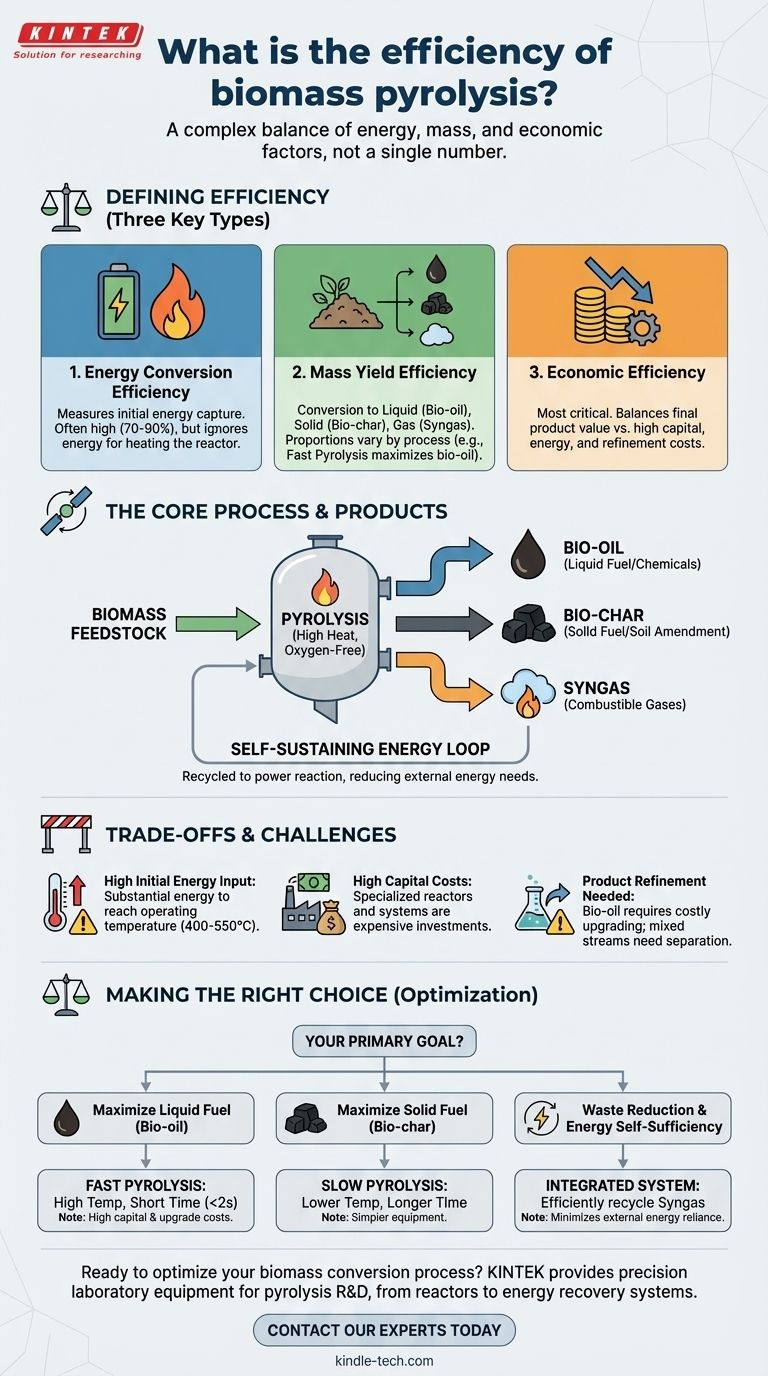

Defining "Efficiency" in Biomass Pyrolysis

To understand the viability of pyrolysis, you must look beyond a single percentage and evaluate three distinct types of efficiency.

Energy Conversion Efficiency

This metric measures how much of the initial energy content of the raw biomass is captured in the final products. Pyrolysis is very effective at this, preserving a large fraction of the original energy.

However, this number does not account for the energy required to heat the reactor to its operating temperature (400-550°C), which is a significant operational cost.

Mass Yield Efficiency

This refers to how the initial mass of the biomass is converted into the three product streams: liquid (bio-oil), solid (bio-char), and gas (syngas).

The proportions of these products are not fixed. They can be manipulated by changing process parameters like temperature and time, allowing operators to target a specific output. For example, fast pyrolysis uses high temperatures and short residence times (less than two seconds) to maximize the liquid bio-oil yield.

Economic Efficiency

This is often the most critical and challenging aspect. It weighs the value of the final products against the total cost of production.

High capital costs for equipment, high energy consumption for heating, and the significant expense of separating and purifying the mixed product stream are major disadvantages that impact economic viability.

The Core Process and Its Products

Understanding the fundamental transformation is key to evaluating its efficiency.

What Pyrolysis Actually Does

At its core, pyrolysis uses high heat in an oxygen-free environment. This process drives off water and volatile compounds, breaking down the complex organic matter of the biomass.

The goal is to concentrate the carbon into more stable and energy-dense forms, effectively creating a set of valuable, storable resources from low-value waste or raw material.

The Three Key Products

The process splits one input stream (biomass) into three distinct outputs:

- Bio-oil: A dark, thick liquid that can be refined into transportation fuels or used to produce specialty chemicals.

- Bio-char: A stable, carbon-rich solid similar to charcoal. It can be used as a fuel, a soil amendment to improve agriculture, or for carbon sequestration.

- Syngas: A mixture of combustible gases (including hydrogen, carbon monoxide, and methane).

The Self-Sustaining Energy Loop

A crucial feature of modern pyrolysis plants is the ability to use the syngas produced during the process as fuel.

This gas is often recycled directly back to the chamber to provide the heat needed for the reaction. This creates a self-sustaining loop that dramatically reduces the need for external energy inputs once the process is running, significantly improving the net energy efficiency.

Understanding the Trade-offs and Challenges

Objectivity requires acknowledging the significant hurdles that impact the real-world efficiency of pyrolysis.

High Initial Energy Input

Even with a self-sustaining gas loop, the system requires a substantial amount of energy to reach its high operating temperature. This initial energy cost is a primary operational expense.

High Capital Costs

Pyrolysis reactors, feeding systems, and product collection units are specialized and expensive. The high initial investment is a major barrier, especially for smaller-scale applications.

The Problem of Product Refinement

The outputs of pyrolysis are not immediately ready for use. Raw bio-oil, for instance, is acidic, unstable, and contains too much water and oxygen to be used as a "drop-in" transportation fuel.

It requires costly and energy-intensive upgrading, which can make it less cost-effective than its fossil fuel counterparts. Similarly, the mixed product stream must be separated and purified, adding complexity and expense.

Making the Right Choice for Your Goal

The "best" pyrolysis setup is the one that is most efficient at producing your desired outcome.

- If your primary focus is producing liquid fuel (bio-oil): Fast pyrolysis is the most effective method, but you must budget for the high capital costs and the significant downstream expense of upgrading the oil.

- If your primary focus is maximizing solid fuel (bio-char): A slower, lower-temperature pyrolysis process is typically more efficient and uses simpler, less expensive equipment.

- If your primary focus is waste reduction and energy self-sufficiency: The key is a well-integrated system that efficiently captures and uses its own syngas to power the operation, minimizing reliance on external energy sources.

Ultimately, evaluating the true efficiency of biomass pyrolysis requires looking past a simple energy conversion number and focusing on the economic realities of the entire end-to-end process.

Summary Table:

| Pyrolysis Type | Target Product | Key Process Conditions |

|---|---|---|

| Fast Pyrolysis | Maximize Bio-oil | High temperature, short residence time (<2 sec) |

| Slow Pyrolysis | Maximize Bio-char | Lower temperature, longer residence time |

| Integrated System | Energy Self-Sufficiency | Syngas recycled to power the reactor |

Ready to optimize your biomass conversion process?

At KINTEK, we specialize in advanced laboratory equipment for pyrolysis research and development. Whether you're focused on maximizing bio-oil yield, producing high-quality bio-char, or creating an energy-efficient system, our expertise and reliable equipment can help you achieve your goals.

We provide:

- Precision pyrolysis reactors for controlled experiments

- Robust systems designed for efficient energy recovery

- Solutions tailored to your specific biomass feedstock and target products

Let's build a more efficient and sustainable future together. Contact our experts today to discuss your project needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is the temperature range for calcination? Master the 800°C to 1300°C Process

- What can you do with pyrolysis oil? Turn Waste into Power, Fuel, and Chemicals

- What are the products of pyrolysis waste? Turn Waste into Bio-Char, Bio-Oil, and Syngas

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What is spray pyrolysis method? A Guide to Precision Thin Film & Powder Synthesis

- What is the difference between pyrolysis and incomplete combustion? The Critical Role of Oxygen in Thermal Processes

- What is the difference between pyrolysis and torrefaction? Choose the Right Biomass Conversion Process