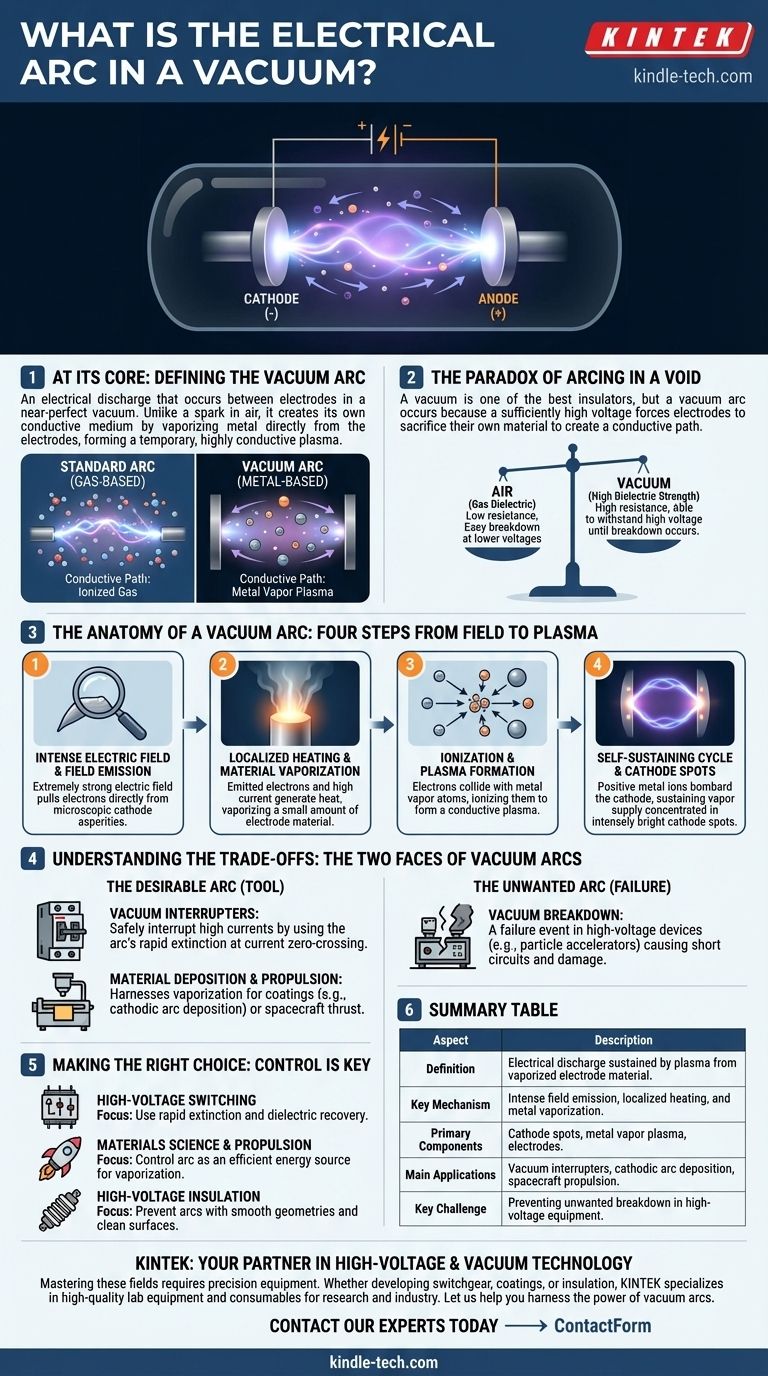

At its core, a vacuum arc is an electrical discharge that occurs between two electrodes in a near-perfect vacuum. Unlike a spark in air, which uses gas molecules as its conductive path, a vacuum arc creates its own conductive medium. It does this by vaporizing metal directly from the surfaces of the electrodes, forming a temporary, highly conductive plasma of metal ions and electrons that sustains the current flow.

A vacuum is one of the best known electrical insulators. The paradox of a vacuum arc is that it occurs precisely because there is no gas; a sufficiently high voltage forces the electrodes to sacrifice their own material to create a conductive path where none existed.

The Paradox of Arcing in a Void

To understand a vacuum arc, we must first appreciate why it seems impossible. The behavior is completely different from the arcs we experience in our daily environment.

The Role of Air in a Standard Arc

A familiar arc, like lightning or the spark from a welding machine, is an electrical breakdown of a gas. A high voltage strips electrons from air molecules (like nitrogen and oxygen), creating a channel of ionized gas—a plasma—that is highly conductive. The gas itself is the medium for the arc.

The Vacuum's High Dielectric Strength

A vacuum, by contrast, has a very high dielectric strength. With virtually no atoms or molecules between the electrodes, there is nothing to ionize. Therefore, a vacuum should be a near-perfect insulator, capable of withstanding extremely high voltages without breaking down.

The Anatomy of a Vacuum Arc: From Field to Plasma

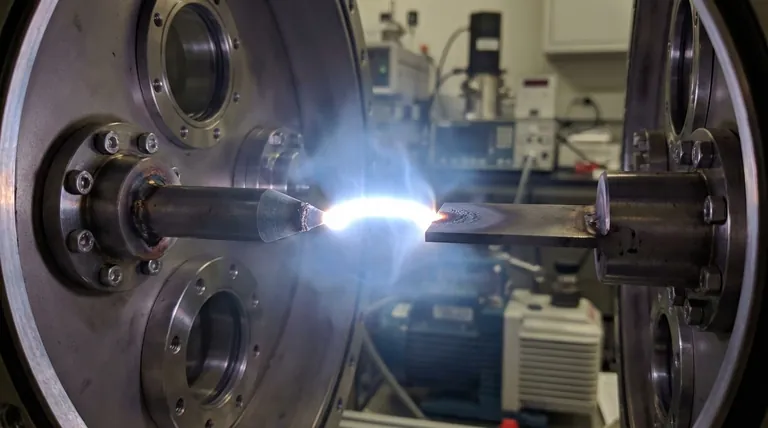

A vacuum arc is initiated by a process known as vacuum breakdown. It is a sequence of events that turns a solid electrode into a temporary plasma bridge.

Step 1: Intense Electric Field and Field Emission

It all begins with an extremely strong electric field (millions of volts per meter) between the cathode (negative electrode) and the anode (positive electrode). This field is so intense at microscopic sharp points, or "asperities," on the cathode surface that it can pull electrons directly out of the metal in a process called field electron emission.

Step 2: Localized Heating and Material Vaporization

These emitted electrons accelerate across the vacuum gap and bombard the anode, causing intense, localized heating. At the same time, the high current flowing through the microscopic cathode asperities also generates extreme heat. This combined heating is sufficient to vaporize a small amount of the electrode material, creating a neutral cloud of metal vapor.

Step 3: Ionization and Plasma Formation

The electrons streaming from the cathode then collide with the atoms in this metal vapor cloud. These collisions are energetic enough to knock electrons off the metal atoms, ionizing them and creating a plasma composed of positive metal ions and free electrons. This plasma is the conductive medium of the vacuum arc.

Step 4: The Self-Sustaining Cycle and Cathode Spots

Once formed, the plasma becomes a self-sustaining system. The cloud of positive metal ions is drawn back to the negatively charged cathode, bombarding it and causing more material to vaporize and sputter away. This creates a continuous supply of metal vapor to fuel the arc. This entire process is concentrated in tiny, intensely bright, and rapidly moving points on the cathode called cathode spots.

Understanding the Trade-offs: The Two Faces of Vacuum Arcs

A vacuum arc is not inherently good or bad; its value depends entirely on the application. It can be a powerful tool or a catastrophic failure.

The Desirable Arc: Vacuum Interrupters

In medium- and high-voltage switchgear, vacuum interrupters are designed to intentionally create and then extinguish a vacuum arc. When the contacts separate to interrupt a high current, an arc forms. However, because the arc relies on vapor from the electrodes, it extinguishes almost instantly when the AC current crosses zero. The vacuum's high dielectric strength then immediately returns, preventing the arc from re-igniting.

The Creative Arc: Material Deposition and Propulsion

The ability of a vacuum arc to vaporize material is harnessed in industrial processes. In cathodic arc deposition, an arc is used to vaporize a source material (like titanium), which then coats a substrate to form an extremely hard, durable thin film (like TiN). A similar principle is used in some forms of advanced spacecraft propulsion.

The Unwanted Arc: Vacuum Breakdown

In many other high-voltage devices, such as particle accelerators, X-ray tubes, and satellite electronics, a vacuum arc is a failure event. An unintended arc can cause a short circuit, permanently damage electrode surfaces, and compromise the integrity of the entire system. Preventing this type of breakdown is a major focus of high-voltage engineering.

Making the Right Choice: Harnessing or Preventing the Arc

Your approach to the vacuum arc depends entirely on your objective. The key is to control the conditions that allow it to form.

- If your primary focus is high-voltage switching: The key is to use the arc's rapid extinction at the current zero-crossing and the vacuum's fast dielectric recovery to safely interrupt massive electrical currents.

- If your primary focus is materials science or propulsion: The key is to control the arc as a highly efficient energy source for vaporizing solid material to create coatings or generate thrust.

- If your primary focus is high-voltage insulation: The key is to prevent arcs by designing smooth electrode geometries that minimize electric field stress and by ensuring surfaces are impeccably clean.

Ultimately, understanding the vacuum arc is about mastering the physics that turns a solid metal component into a temporary, conductive plasma.

Summary Table:

| Aspect | Description |

|---|---|

| Definition | An electrical discharge sustained by a plasma created from vaporized electrode material. |

| Key Mechanism | Intense electric fields cause field emission, localized heating, and vaporization of metal to form a conductive plasma. |

| Primary Components | Cathode spots, metal vapor plasma, anode and cathode electrodes. |

| Main Applications | Vacuum interrupters (switching), cathodic arc deposition (coatings), spacecraft propulsion. |

| Key Challenge | Preventing unwanted breakdown in high-voltage equipment like particle accelerators and X-ray tubes. |

Mastering high-voltage and vacuum technology requires precision equipment and deep expertise. Whether you are developing advanced switchgear, creating durable thin-film coatings, or pushing the limits of high-voltage insulation, KINTEK is your trusted partner. We specialize in providing high-quality lab equipment and consumables tailored to the demanding needs of research and industrial laboratories.

Let us help you harness the power of vacuum arcs for your next breakthrough. Contact our experts today to discuss your specific application and discover the right solutions for your laboratory.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of using a high-temperature vacuum degassing furnace? Ensure High-Density ODS FeCrAl Alloy Quality

- How would vacuum affect the boiling point of a compound? Lower Boiling Points for Safer, More Efficient Processing

- What furnace is used for heat treatment? Match Your Process to the Perfect Equipment

- Why is brazing more extensively used in industrial practice? Unlock High-Strength, Automated Joining

- What is the significance of using a high-temperature sintering furnace for PRP? Optimize Preform Structural Engineering

- What role does a vacuum oven play in Li3InCl6-coated VGCF drying? Optimize Conductive Agent Synthesis

- What conditions does a vacuum annealing furnace provide for Ti41.5Zr41.5Ni17 films? Optimize Quasicrystal Stability

- What role do high-temperature furnaces play in LFR corrosion testing? Achieve Critical Thermal Stability