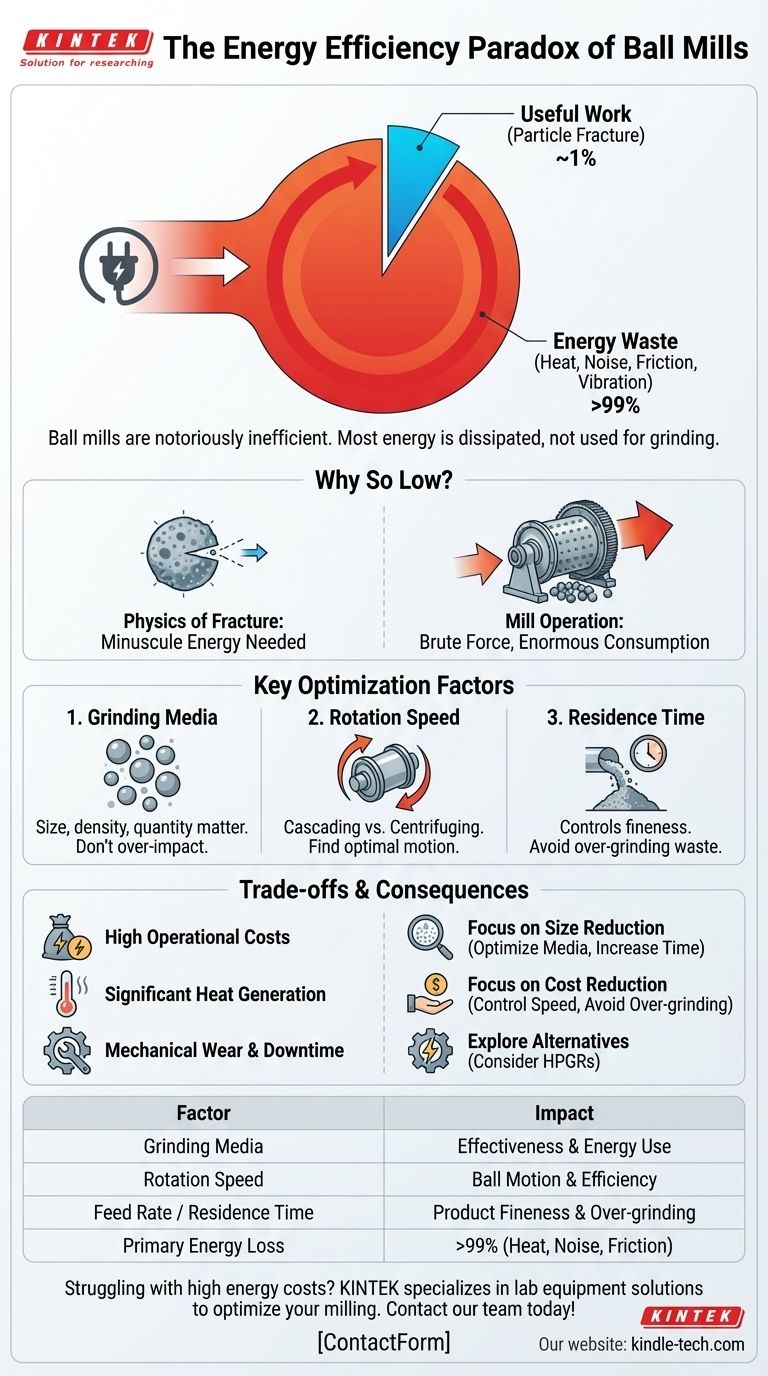

In short, the energy efficiency of a typical ball mill is extremely low. For processes like mineral grinding, only about 1% of the total energy consumed is used to actually break down the material. The vast majority, over 99%, is lost to the environment as heat, noise, and mechanical friction.

The central challenge of ball milling is not achieving high efficiency—which is physically improbable—but rather understanding and minimizing the immense energy waste. Optimization focuses on controlling operational parameters to reduce this waste, not on fundamentally changing the low efficiency of the process itself.

Why Ball Mill Efficiency is So Low

The primary purpose of a ball mill is comminution, the process of reducing the size of solid particles. The only "useful" work is the energy that goes into creating new surface area by fracturing these particles.

The Physics of Fracture vs. Operation

The energy required to create a new fracture surface in a particle is minuscule. However, a ball mill operates through brute force—lifting and dropping heavy grinding media (the balls).

This process of lifting, tumbling, and impact consumes an enormous amount of energy. The actual particle-breaking event is a tiny fraction of the total energy exchange happening inside the mill.

Where the Energy Really Goes: Heat and Noise

Well over 99% of the input energy is converted into other forms:

- Heat: Generated from friction between the balls, the material, and the mill liner.

- Noise: Created by the constant impact of the balls against each other and the mill shell.

- Vibration: Transmitted through the machine and into its foundation.

This massive energy loss is an inherent characteristic of impact-based grinding. Even highly optimized crushing machines rarely exceed 8% efficiency.

Key Factors Influencing Grinding Performance

While overall efficiency remains low, several operational variables can be adjusted to maximize the effectiveness of the grinding process and minimize wasted effort.

Grinding Media Characteristics

The size, density, and quantity of the balls are critical. The media must be large and heavy enough to fracture the largest feed particles but not so large that energy is wasted on unnecessarily powerful impacts.

Mill Rotation Speed

Speed determines how the balls behave. Too slow, and the balls merely slide, providing little grinding action. Too fast, and they centrifuge, pinning themselves to the mill wall and not falling at all. The optimal speed creates a "cascading" or "cataracting" motion that maximizes impacts.

Material Feed and Residence Time

The rate at which material is fed into the mill determines how long it stays inside (residence time). A longer residence time produces a finer product, but it can also lead to over-grinding, where energy is wasted pulverizing particles that have already reached the target size.

Understanding the Trade-offs and Consequences

The low energy efficiency of ball mills has significant practical and financial implications that must be managed.

High Operational Costs

Energy is the single largest cost in most grinding operations. The inherent inefficiency of a ball mill means that it will always be an energy-intensive process with high electricity consumption. This is especially true when producing nano-sized particles.

Significant Heat Generation

The transformation of energy into heat is not just a waste; it can be a problem. For heat-sensitive materials, the temperature inside the mill may need to be controlled with cooling systems, adding further cost and complexity.

Mechanical Wear and Downtime

The same forces that grind the material also cause wear on the grinding media and the mill liners. This leads to recurring maintenance costs for replacing components and process downtime.

Making the Right Choice for Your Goal

Optimizing a ball mill is a balancing act. Your primary objective will determine which parameters you should prioritize.

- If your primary focus is maximum size reduction: Concentrate on optimizing the grinding media (size and material) and increasing residence time, accepting that this will likely increase energy consumption per ton.

- If your primary focus is minimizing operational cost: Carefully control the mill speed and feed rate to operate in the most effective range and avoid over-grinding already-fine particles.

- If you are evaluating new technologies: Acknowledge the fundamental energy limits of ball mills and investigate higher-efficiency alternatives like High-Pressure Grinding Rolls (HPGRs) if they are suitable for your material.

Understanding these energy dynamics is the first step toward optimizing your comminution process for both performance and cost.

Summary Table:

| Key Factor | Impact on Grinding Performance |

|---|---|

| Grinding Media | Size, density, and quantity affect fracture effectiveness and energy use. |

| Rotation Speed | Determines ball motion (cascading vs. centrifuging), directly impacting efficiency. |

| Feed Rate / Residence Time | Controls product fineness; incorrect settings lead to over-grinding and waste. |

| Primary Energy Loss | Over 99% of input energy is lost as heat, noise, and mechanical friction. |

Struggling with high energy costs and inefficient grinding? KINTEK specializes in lab equipment and consumables, providing solutions to help you optimize your milling processes. Our experts can help you select the right equipment and operational parameters to maximize performance and minimize waste. Contact our team today to discuss how we can improve your lab's efficiency and reduce costs!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary function of a high-energy ball mill for LPSC? Optimize Sulfide Electrolyte Surface Modification

- What particle size can be obtained through ball mill? From Microns to Nanometers with Precision Control

- What is the primary function of a planetary ball mill in preparing ODS high-entropy alloy? Unlock Mechanical Alloying

- What role does a planetary ball mill play in the pretreatment of B4C/Al composite powders? Optimize Your Metal Matrix

- What is the specific function of a planetary ball mill in preparing Cr-50 wt% Si alloy? Master Mechanical Alloying

- What role does a planetary ball mill play in the synthesis of LZTC solid-state electrolytes? Enhancing Ionic Conductivity

- What function does a ball mill serve in LLZO synthesis? Maximize Your Solid-State Electrolyte Purity

- What is the primary role of mechanical alloying equipment in Fe-doped CoSb3 synthesis? Master Nanostructured Alloying