The ideal heat source for silver brazing depends entirely on the application's scale, complexity, and need for repeatability. While a simple torch is often the first tool considered, the best method is the one that heats the entire joint area evenly and quickly to the correct temperature. The most common and effective heat sources are manual torches, induction heating systems, and controlled-atmosphere furnaces.

The core challenge in silver brazing is not just melting the filler metal, but achieving uniform heat in the base metals on both sides of the joint. The "best" heat source is the one that provides the most control and efficiency for your specific part geometry and production volume.

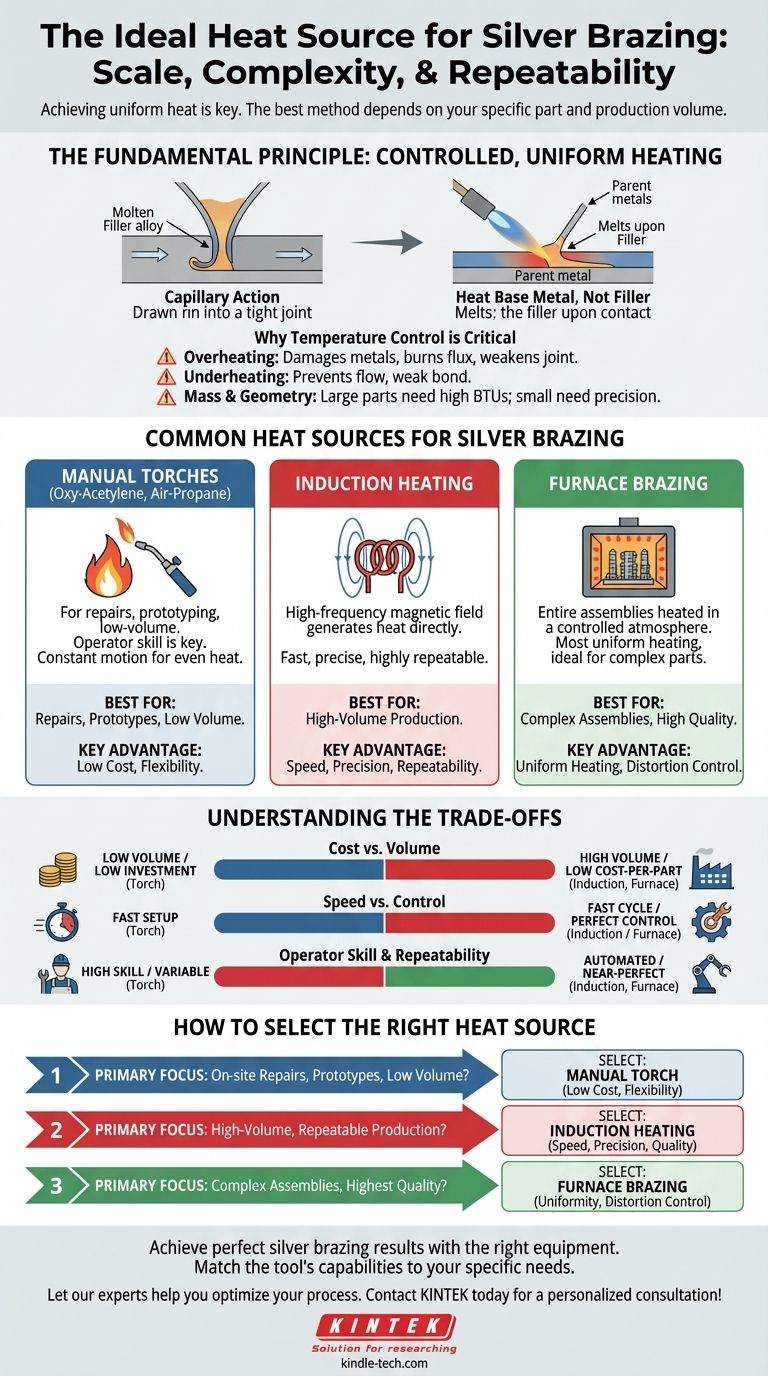

The Fundamental Principle: Controlled, Uniform Heating

Before choosing a tool, it's critical to understand the goal. Silver brazing relies on capillary action, where the molten filler alloy is drawn into a tight-fitting joint. This only works if the entire joint is at the proper, uniform temperature.

Why Temperature Control is Critical

Silver brazing alloys have a relatively low and narrow melting range. Overheating the assembly can damage the base metals, burn the flux (rendering it useless), and weaken the final joint. Underheating will prevent the filler metal from flowing and bonding correctly.

Heating the Base Metal, Not the Filler

A common mistake is to apply heat directly to the brazing alloy. The correct technique is to heat the parent metals that form the joint. When the base metals reach the filler's flow temperature, they will melt the alloy upon contact, drawing it deep into the joint for a strong, complete bond.

The Role of Mass and Geometry

The size, thickness, and shape of the parts being joined dictate the heating requirements. A large, heavy component requires a heat source with high thermal output (BTUs) to bring it to temperature quickly, while a small, delicate assembly needs a precise and less intense heat source to avoid distortion or melting.

Common Heat Sources for Silver Brazing

Each heating method offers a different balance of speed, control, cost, and repeatability.

Manual Torches (Oxy-Acetylene, Air-Propane)

This is the most common method for repair work, prototyping, and low-volume production. An operator uses a handheld torch to manually heat the assembly.

The key is to use a slightly reducing or neutral flame and keep it in constant motion to distribute heat evenly. The choice between fuel gases like propane or acetylene depends on the required temperature and the mass of the parts.

Induction Heating

Induction heating uses a high-frequency alternating magnetic field to generate heat directly within the metal parts. An induction coil is custom-designed to surround the joint area.

This method is exceptionally fast, precise, and highly repeatable. It is the gold standard for high-volume, automated production lines where consistency is paramount.

Furnace Brazing

In this method, entire assemblies are pre-loaded with brazing alloy and flux (or placed in a flux-free controlled atmosphere) and heated in a furnace.

Furnace brazing provides the most uniform heating possible, making it ideal for extremely complex assemblies with multiple joints or parts that are prone to distortion. It is a batch process well-suited for medium to high production volumes.

Understanding the Trade-offs

There is no single "best" heat source, only the most appropriate one for the job. The decision involves clear trade-offs.

Cost vs. Volume

Manual torches have a very low initial investment, making them perfect for one-off jobs. Induction heating systems carry a high upfront cost for equipment and coil design but offer a very low cost-per-part in high-volume production.

Speed vs. Control

Induction heating is the fastest method per cycle, often taking only seconds. Furnace brazing has a long cycle time but offers perfect thermal control. Torches are fast to set up but rely entirely on operator skill for both speed and quality.

Operator Skill and Repeatability

Brazing with a torch is an art that requires a skilled and experienced operator to achieve consistent results. Induction and furnace brazing remove this variability, providing near-perfect repeatability once the process is dialed in.

How to Select the Right Heat Source

Match the heating method to your primary objective for a successful and cost-effective outcome.

- If your primary focus is on-site repairs, one-off prototypes, or low-volume work: A manual torch offers the best balance of low cost and operational flexibility.

- If your primary focus is high-volume, repeatable production of a consistent part: Induction heating is the superior choice for its unmatched speed, precision, and quality control.

- If your primary focus is brazing complex assemblies or achieving the highest-possible joint quality: Furnace brazing provides the most uniform heating and is ideal for parts with multiple or hard-to-reach joints.

Ultimately, selecting the right heat source is about matching the tool's capabilities for controlled heating to the unique demands of your specific part and production goals.

Summary Table:

| Heat Source | Best For | Key Advantage |

|---|---|---|

| Manual Torch | Repairs, Prototypes, Low Volume | Low Cost, Flexibility |

| Induction Heating | High-Volume Production | Speed, Precision, Repeatability |

| Furnace Brazing | Complex Assemblies, High Quality | Uniform Heating, Distortion Control |

Achieve perfect silver brazing results with the right equipment.

Selecting the ideal heat source is critical for joint strength, production efficiency, and cost-effectiveness. Whether you need the flexibility of a torch for repairs, the speed of induction for high-volume runs, or the unparalleled uniformity of a furnace for complex parts, KINTEK has the solution.

As a specialist in lab equipment and consumables, we provide the precise, reliable heating systems your laboratory or production facility needs for consistent, high-quality brazing.

Let our experts help you optimize your process. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency

- What are the different types of brazing welding? A Guide to Choosing the Right Heat Source