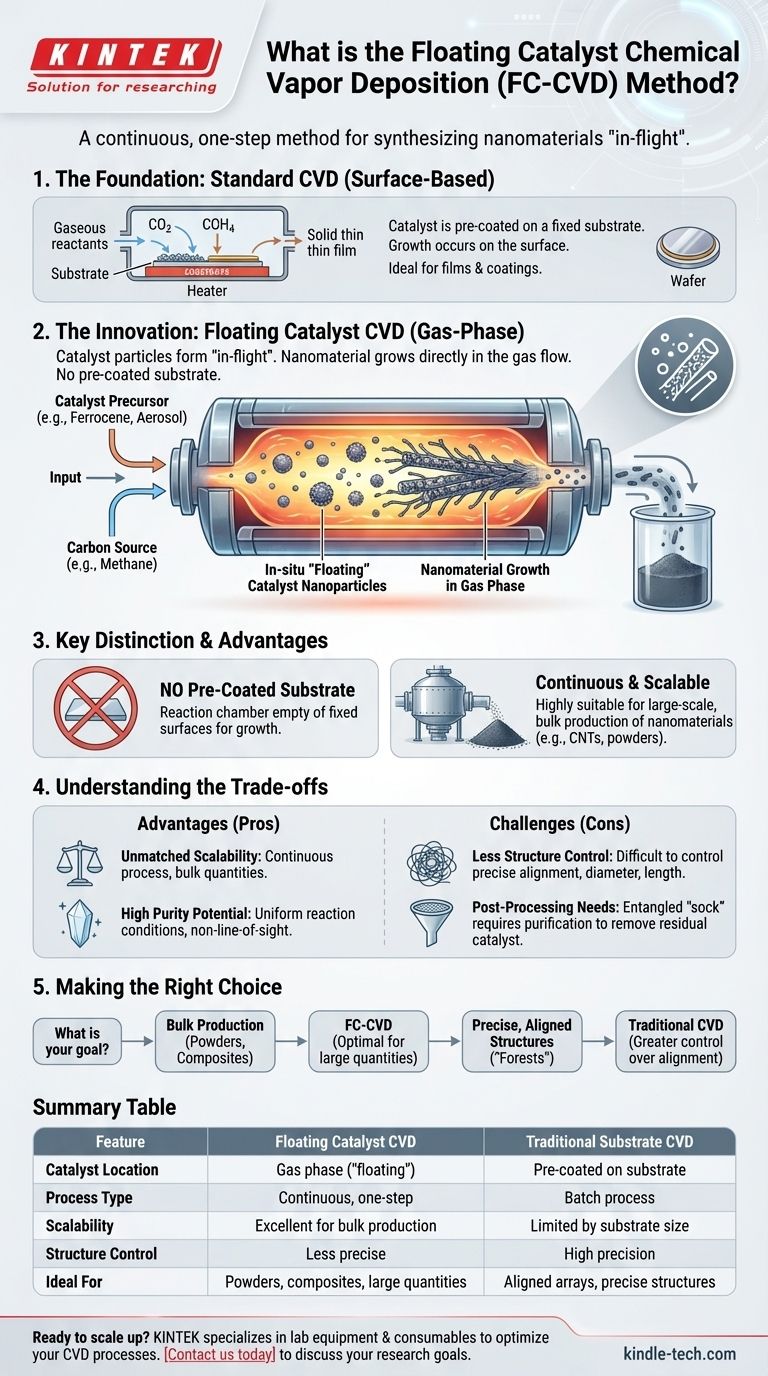

In essence, floating catalyst chemical vapor deposition (FC-CVD) is a method for synthesizing nanomaterials, like carbon nanotubes, where the catalyst is not fixed to a surface. Instead, a catalyst precursor is introduced as a gas or aerosol directly into a high-temperature reactor along with the carbon source, allowing the catalyst particles to form "in-flight" and grow the desired material in the gas phase.

The core distinction of the floating catalyst method is its one-step, continuous nature. Unlike traditional methods that grow materials on a pre-coated substrate, FC-CVD forms the catalyst and grows the nanomaterial simultaneously within the reaction chamber, making it highly suitable for large-scale production.

How Standard Chemical Vapor Deposition (CVD) Sets the Stage

To understand the floating catalyst innovation, we must first understand the foundation it's built upon: standard Chemical Vapor Deposition (CVD).

The Basic Principle

At its core, CVD is a process for creating high-performance, solid thin films or coatings. A substrate, or workpiece, is placed inside a reaction chamber.

Gaseous reactant molecules are introduced into the chamber, which then decompose and react at the substrate's surface, leaving behind the desired solid material.

Key Components of a CVD System

A typical CVD setup includes a gas delivery system to introduce reactants, a reaction chamber to contain the process, and an energy source (like a furnace) to provide the heat needed for the chemical reactions. It also requires a vacuum and exhaust system to control the environment and remove byproducts.

The "Floating Catalyst" Innovation: A Key Distinction

Floating Catalyst CVD modifies this fundamental process by completely changing how and where the growth is initiated. It moves the action from a static surface into the dynamic gas flow itself.

Eliminating the Pre-Coated Substrate

In many traditional CVD processes for nanomaterials, a thin layer of catalyst (like iron or nickel) is first deposited onto a solid substrate. The growth of the material, such as carbon nanotubes, then occurs on this fixed surface.

FC-CVD eliminates this step entirely. The reactor is empty of any pre-coated surfaces intended for growth.

In-Situ Catalyst Formation

The critical step is the introduction of a catalyst precursor—often an organometallic compound like ferrocene—along with the primary reactant (the carbon source, such as methane or ethanol).

Inside the hot zone of the reactor, the high temperature causes the precursor molecule to decompose. This decomposition releases metal atoms, which then cluster together to form nanometer-sized liquid or solid particles—the "floating" catalysts.

Gas-Phase Nucleation and Growth

These newly formed catalyst nanoparticles are suspended and carried along in the gas flow. As they travel, they interact with the carbon source gas, which decomposes on their surface.

This interaction catalyzes the growth of the desired nanomaterial, such as a carbon nanotube, directly from the floating particle. The result is a continuous synthesis of material within the reactor volume, not on its walls.

Understanding the Trade-offs

Like any specialized technical process, FC-CVD has clear advantages and specific challenges that make it suitable for some applications but not others.

Advantage: Unmatched Scalability

Because the process is continuous and not limited by the surface area of a substrate, FC-CVD is exceptionally well-suited for producing large, bulk quantities of nanomaterials. Material can be collected continuously at the reactor's outlet.

Advantage: High Purity Potential

The direct gas-phase synthesis can lead to materials with high structural quality and purity. The non-line-of-sight nature of the process, a general advantage of CVD, ensures uniform reaction conditions.

Challenge: Less Control Over Structure

A significant trade-off is the difficulty in precisely controlling the final material's structure. Compared to substrate-based methods, controlling the diameter, length, and alignment of the resulting nanomaterials is more complex in a floating catalyst system.

Challenge: Post-Processing Needs

The final product is often an entangled, low-density mass (sometimes called an aerogel or "sock") that contains residual catalyst particles. This necessitates downstream purification and processing steps to prepare the material for specific applications.

Making the Right Choice for Your Goal

Selecting a synthesis method depends entirely on your end objective. FC-CVD is a powerful tool when used for the right purpose.

- If your primary focus is bulk production: FC-CVD is one of the most effective methods for continuous, large-scale synthesis of nanomaterials like single- and multi-walled carbon nanotubes.

- If your primary focus is creating precisely aligned structures (e.g., "forests"): A traditional, substrate-based CVD method will provide far greater control over alignment and placement.

- If your primary focus is producing powders for composites or additives: FC-CVD is an excellent and direct route to manufacturing high-quality nanomaterial powders in large quantities.

Ultimately, the floating catalyst method transforms nanomaterial synthesis from a surface-based batch process into a continuous, industrial-scale gas-phase production line.

Summary Table:

| Feature | Floating Catalyst CVD | Traditional Substrate CVD |

|---|---|---|

| Catalyst Location | Gas phase ("floating") | Pre-coated on substrate |

| Process Type | Continuous, one-step | Batch process |

| Scalability | Excellent for bulk production | Limited by substrate size |

| Structure Control | Less precise | High precision (alignment, placement) |

| Ideal For | Powders, composites, large quantities | Aligned arrays, precise structures |

Ready to scale up your nanomaterial synthesis? The floating catalyst CVD method is ideal for high-volume production of carbon nanotubes and other advanced materials. At KINTEK, we specialize in providing state-of-the-art lab equipment and consumables tailored to your laboratory's unique needs. Our expertise can help you optimize your CVD processes for maximum efficiency and yield. Contact us today to discuss how our solutions can advance your research and production goals!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Arc Induction Melting Furnace

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method