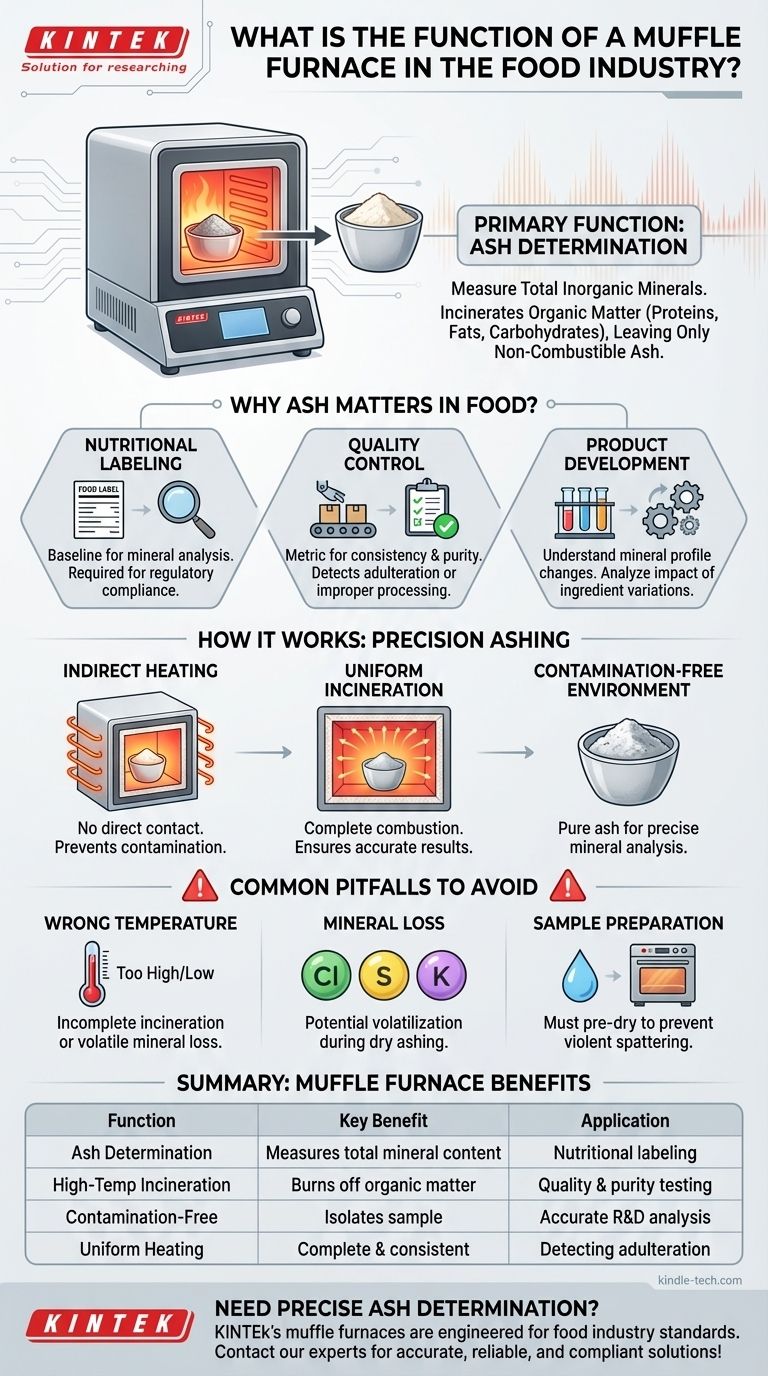

In the food industry, the primary function of a muffle furnace is ash determination. This is a fundamental analytical process used to measure the total amount of inorganic minerals in a food sample. The furnace uses extremely high, controlled temperatures to completely incinerate all organic matter—like proteins, fats, and carbohydrates—leaving behind only the non-combustible ash.

A muffle furnace is not simply a high-temperature oven; it is a precision instrument for chemical analysis. By incinerating a food sample in a controlled, contaminant-free environment, it isolates the total inorganic mineral content (the "ash"), which is a critical indicator of nutritional value and product quality.

What is Ash and Why Does It Matter in Food?

Understanding the purpose of a muffle furnace requires first understanding the importance of "ash" in food science. It is a proxy measurement for the total mineral content of a food product.

Defining "Ash Content"

Ash is the inorganic residue that remains after a food sample has been completely burned away at high temperatures (typically 500-600°C).

This residue consists of the essential and non-essential minerals in the food, such as calcium, potassium, sodium, and iron.

The Role in Nutritional Labeling

The determination of ash content is a crucial first step in analyzing a food's nutritional profile.

Regulatory bodies often require mineral content to be listed on nutritional labels. The total ash value provides a baseline for further, more specific mineral analysis.

A Key Metric for Quality Control

Ash content serves as a vital quality control metric. For many food products, like flour or spices, the expected ash content falls within a very specific range.

A deviation from this range can indicate product adulteration, improper processing, or contamination, making it a quick and effective test for product consistency and purity.

How a Muffle Furnace Enables Accurate Ashing

A muffle furnace is specifically designed to perform this incineration process with the precision required for scientific analysis. Its unique features are what make it indispensable for this task.

The Principle of Indirect, High-Temperature Heating

The furnace works by heating a sample without any direct contact between the heating elements and the sample itself.

The sample is placed inside a separate, insulated chamber—the "muffle"—which is typically made of a ceramic material. This chamber is heated from the outside, ensuring the sample is not contaminated by combustion byproducts or flakes from the heating coils.

Ensuring Uniform Incineration

The insulated muffle absorbs and radiates heat evenly throughout the chamber. This uniform temperature is critical for ensuring that the entire sample is incinerated completely.

Incomplete combustion would leave behind organic matter, leading to an inaccurate (artificially high) ash measurement.

Preventing Contamination for Pure Results

By isolating the sample from the heating elements, a muffle furnace guarantees that the final ash is purely from the food product.

This is the most critical function for analytical accuracy. The goal is to measure what was in the food, not what was in the furnace.

Common Pitfalls to Avoid

While the process is straightforward, achieving accurate results requires careful attention to detail. Certain mistakes can compromise the integrity of the analysis.

The Importance of Correct Temperature

Using the wrong temperature is a common error. If the temperature is too low, incineration will be incomplete.

Conversely, if the temperature is too high, certain minerals may vaporize and be lost (a process called volatilization), leading to an artificially low reading. Standardized methods dictate precise temperatures for different food types.

Potential for Mineral Loss

Even at correct temperatures, some minerals like chlorine, sulfur, and potassium can be partially lost during dry ashing.

Understanding these limitations is important for interpreting the results, especially when analyzing for specific volatile minerals.

Sample Preparation is Crucial

The sample must be properly prepared before being placed in the furnace. It is often pre-dried to remove all moisture.

Failing to remove moisture can cause the sample to spatter violently when heated, leading to sample loss and inaccurate results.

Applying This to Your Goal

The data from a muffle furnace serves different purposes depending on your objective.

- If your primary focus is nutritional labeling: Use ashing as the definitive method to determine the total mineral content for regulatory compliance and consumer information.

- If your primary focus is quality control: Implement ash testing as a routine check to monitor the consistency of raw ingredients and finished products against established standards.

- If your primary focus is product development: Analyze the ash content of new formulations to understand how ingredient changes impact the final mineral profile.

Ultimately, the muffle furnace provides an unassailable, foundational data point for ensuring the safety, quality, and nutritional accuracy of food products.

Summary Table:

| Function | Key Benefit | Application in Food Industry |

|---|---|---|

| Ash Determination | Measures total inorganic mineral content | Nutritional labeling compliance |

| High-Temperature Incineration | Burns off all organic matter completely | Product quality and purity testing |

| Contamination-Free Environment | Isolates sample from heating elements | Accurate mineral analysis for R&D |

| Uniform Heating | Ensures complete and consistent incineration | Detecting adulteration and contamination |

Need precise ash determination for your food products? KINTEK's muffle furnaces are engineered for the exacting standards of the food industry, providing the accuracy and reliability you need for nutritional labeling, quality control, and product development. Our lab equipment ensures your results are contamination-free and fully compliant. Contact our experts today to find the perfect solution for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the other name of muffle furnace? Discover Its Key Function as an Electric or Resistance Furnace

- What is the difference between sintering and firing? A Guide to Thermal Process Terminology

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement

- What is the function of a high-temperature muffle furnace in the preparation of NbOx-SiO2 catalysts? Transform Precursors

- What is the function of a constant temperature drying oven in Yttrium Oxide preparation? Achieve Ultrafine Dispersion

- What role does a high-temperature muffle furnace play in salt bath oxidation? Optimize Thermal Kinetics for Simulation

- What is the maximum temperature of a muffle furnace? Find the Right Heat for Your Application

- Why is an industrial oven essential for the gelation of carbon xerogels? Ensuring Precise Cross-Linking and Stability