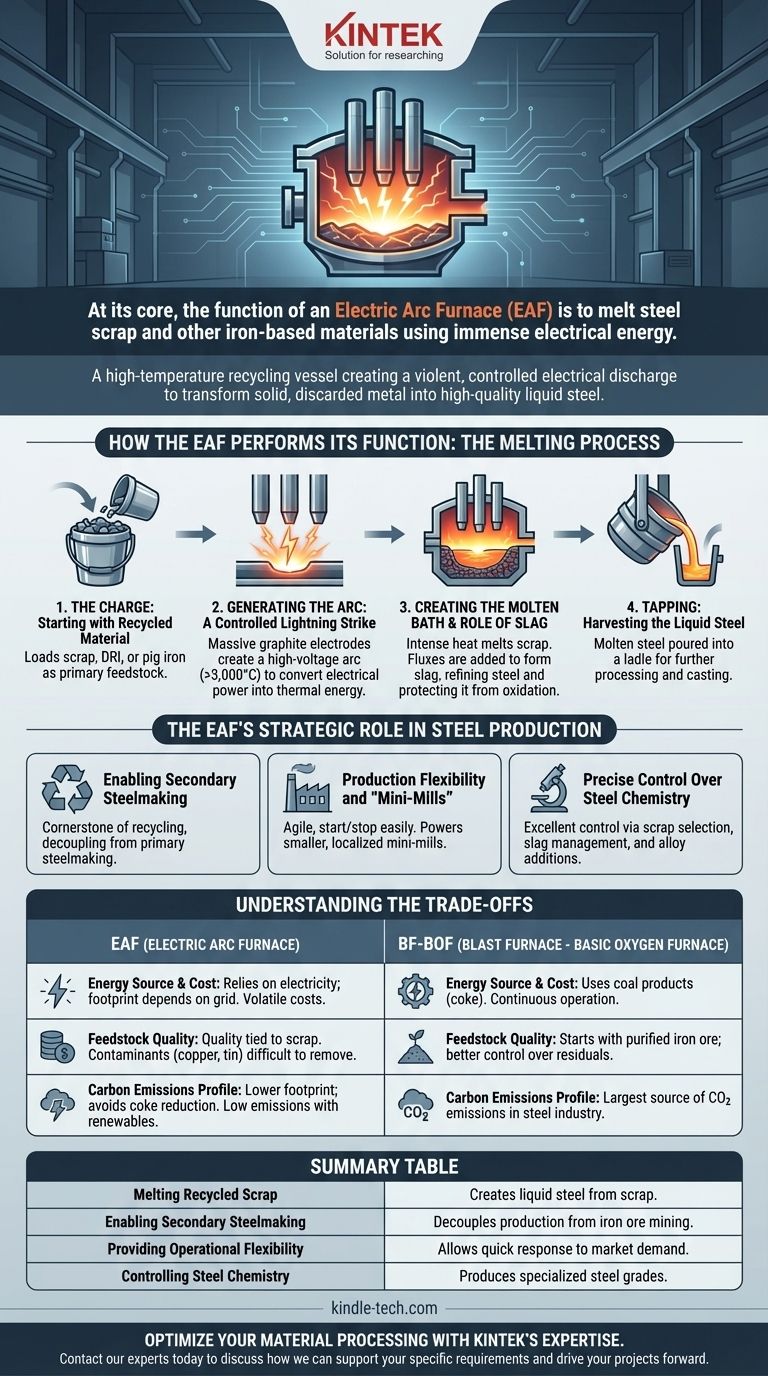

At its core, the function of an Electric Arc Furnace (EAF) is to melt steel scrap and other iron-based materials using immense electrical energy. It serves as a high-temperature recycling vessel, creating a violent, controlled electrical discharge—an arc—to transform solid, discarded metal into high-quality liquid steel ready for new applications.

An Electric Arc Furnace is more than just a melting pot; it's the heart of modern secondary steelmaking. Its primary function is not just to melt metal, but to provide a highly flexible and efficient method for recycling steel, decoupling production from the traditional, carbon-intensive process of mining and refining iron ore.

How the EAF Performs Its Function: The Melting Process

To understand the function of an EAF, you must first understand its operational sequence. It is a batch process, meaning it melts one "charge" of material at a time in a series of carefully controlled steps.

The Charge: Starting with Recycled Material

The process begins by loading the furnace with its primary feedstock, known as the charge. This is typically a mix of recycled steel scrap, but it can also include direct reduced iron (DRI) or pig iron to control the final chemistry.

Generating the Arc: A Controlled Lightning Strike

Once the furnace is charged and the roof is closed, three massive graphite electrodes are lowered into the scrap. An extremely high-voltage electric current is passed through them, creating a powerful arc that leaps from the electrode tips to the metal charge.

This arc is the primary source of energy, converting electrical power into intense thermal energy. It's akin to a continuous, controlled lightning strike that can reach temperatures over 3,000°C (5,400°F).

Creating the Molten Bath

The intense radiant heat from the arc rapidly melts the scrap metal, forming a pool of liquid steel at the bottom of the furnace known as the molten bath. Chemical energy, such as oxygen injection, is often used to assist the melting and accelerate the process.

The Role of Slag: Refining and Protecting

During the melting process, materials called fluxes (like lime) are added to the furnace. These combine with impurities in the steel to form a liquid layer called slag that floats on top of the molten bath.

This slag serves two critical functions: it absorbs impurities to refine the steel, and it acts as an insulating blanket, protecting the liquid steel from heat loss and atmospheric oxidation.

Tapping: Harvesting the Liquid Steel

Once the steel reaches the desired temperature and chemical composition, the furnace is tilted. The molten steel is poured out through a tap-hole into a large refractory-lined container called a ladle. This process is known as tapping, and the steel is now ready for further processing and casting.

The EAF's Strategic Role in Steel Production

The simple function of melting scrap underpins a major strategic shift in how steel is made globally. The EAF is the enabling technology for a more agile and distributed production model.

Enabling Secondary Steelmaking

The EAF is the cornerstone of secondary steelmaking, which uses recycled material. This stands in contrast to the traditional primary steelmaking route, which uses a Blast Furnace (BF) and Basic Oxygen Furnace (BOF) to convert iron ore into steel.

Production Flexibility and "Mini-Mills"

Unlike a blast furnace, which must run continuously for years, an EAF can be started and stopped relatively easily. This flexibility allows producers to respond quickly to market demand and electricity price fluctuations.

This has enabled the rise of smaller, more localized plants known as "mini-mills," which can be built with lower capital investment and sited closer to scrap sources and customers.

Precise Control Over Steel Chemistry

The EAF process offers excellent control over the final product. By carefully selecting the scrap charge, managing the slag, and making precise alloy additions in the ladle after tapping, producers can create a vast range of specialized steel grades.

Understanding the Trade-offs

While powerful, the EAF is not a universal solution. Its function comes with a distinct set of advantages and challenges compared to the traditional BF-BOF route.

Energy Source and Cost

The EAF's reliance on electricity is both a strength and a weakness. Its environmental footprint is heavily dependent on the local power grid; it produces very low emissions when powered by renewables but can be carbon-intensive if powered by fossil fuels. Electricity costs can also be highly volatile.

Feedstock Quality and Contaminants

The final quality of EAF steel is directly tied to the quality of the scrap metal used. Contaminants in the scrap, such as copper and tin, are difficult to remove and can negatively impact the properties of the finished steel. Primary steelmaking, which starts with purified iron ore, offers more inherent control over these residual elements.

Carbon Emissions Profile

Even with a fossil-fuel-based grid, the EAF route typically has a significantly lower carbon footprint than the BF-BOF route. This is because it avoids the chemical process of reducing iron ore with coke (a coal product), which is the single largest source of CO2 emissions in the steel industry.

How This Applies to Production Goals

Understanding the EAF's function allows you to see why it is chosen for specific strategic goals.

- If your primary focus is sustainability and recycling: The EAF is the definitive technology, as its core function is to turn scrap back into a high-value product with a lower intrinsic carbon footprint.

- If your primary focus is operational flexibility and market responsiveness: The EAF's ability to operate in smaller-scale mini-mills and adjust output on demand makes it the superior choice over the rigid, continuous operation of a blast furnace.

- If your primary focus is producing commodity steel grades where initial purity is paramount: The traditional BF-BOF route remains a dominant force, as it provides greater control over residual elements by starting with virgin iron ore instead of variable scrap.

The Electric Arc Furnace's ultimate function is to power a more agile and circular future for the global steel industry.

Summary Table:

| Key Function | How It Works | Key Outcome |

|---|---|---|

| Melting Recycled Scrap | Uses a high-voltage electric arc (>3000°C) to melt metal | Creates liquid steel from scrap |

| Enabling Secondary Steelmaking | Batch process using scrap as primary feedstock | Decouples production from iron ore mining |

| Providing Operational Flexibility | Can be started/stopped easily; powers mini-mills | Allows quick response to market demand |

| Controlling Steel Chemistry | Precise management of charge, slag, and alloy additions | Produces a wide range of specialized steel grades |

Optimize Your Material Processing with KINTEK's Expertise

Whether you are exploring advanced thermal processing or require reliable equipment for your operations, KINTEK has the solutions and support you need. We specialize in providing high-quality lab equipment and consumables, serving a wide range of industrial and research laboratory needs.

Let us help you achieve greater efficiency and precision in your work. Contact our experts today to discuss how we can support your specific requirements and drive your projects forward.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why is a non-consumable tungsten electrode used in vacuum arc furnaces? Ensuring Purity in Ti-Cr-Al-V Alloys

- What is the difference between a batch furnace and a continuous casting furnace? Choose the Right Furnace for Your Production Line

- What is the brazing process in short note? Master the Key Parameters for Strong Metal Joints

- Why are high-purity argon and vacuum necessary for 14Cr ODS steel? Essential Protection for Mechanical Alloying

- At what temperature is full annealing accomplished by heating? Achieve Maximum Softness for Your Steel

- What is the safety factor of a vacuum chamber? Ensuring Structural Integrity Against Implosion

- What are the core capabilities of a fast pyrolysis furnace in producing lignin-derived bio-oil? Maximize Your Yield

- How does high-temperature heating equipment simulate the service environment of ceramics? Expert Testing Strategies