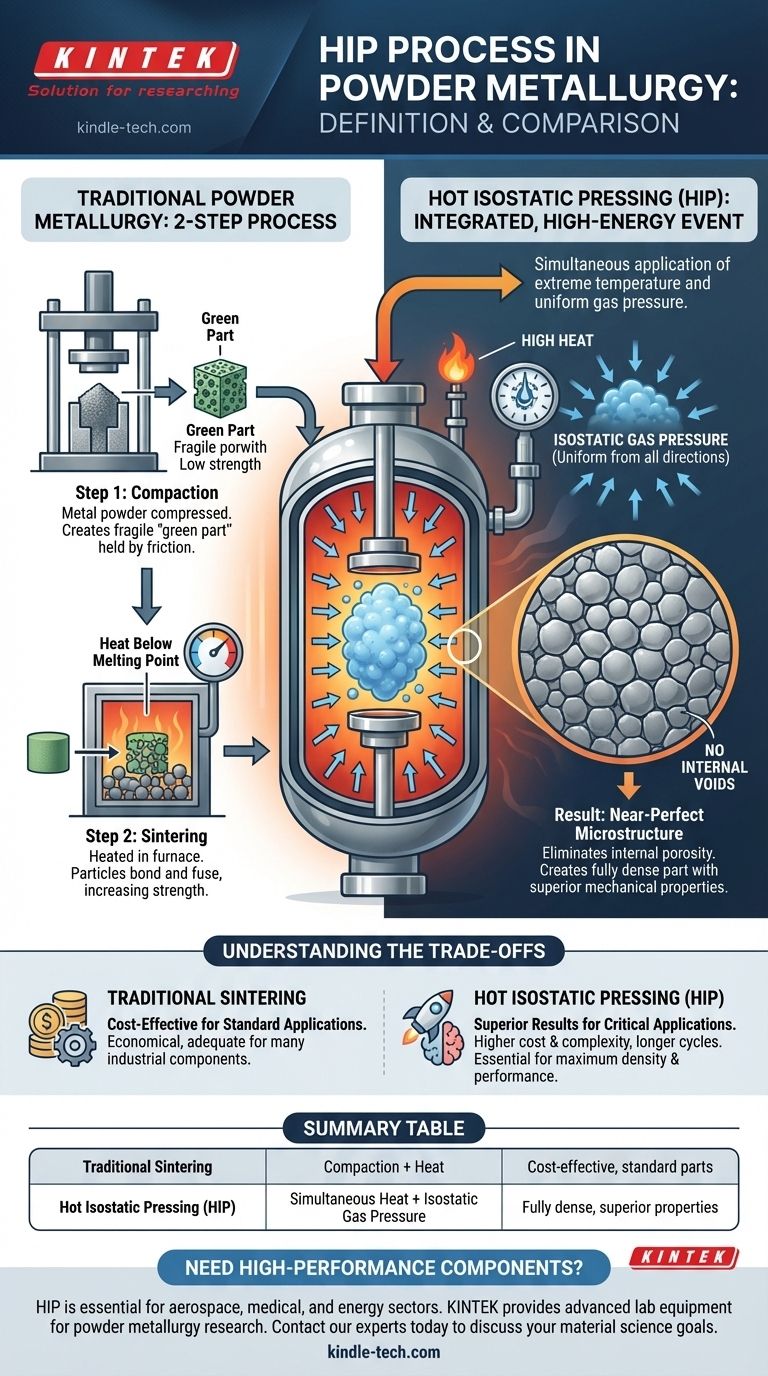

In powder metallurgy, the Hot Isostatic Pressing (HIP) process consolidates metal powders into a fully dense, solid component by applying extremely high temperatures and uniform, gas-based pressure simultaneously. This combination of heat and pressure eliminates internal voids, bonding the powder particles through diffusion to create a final product with a highly uniform internal structure and superior mechanical properties.

Hot Isostatic Pressing is not merely a step in powder metallurgy; it is an advanced, integrated process that combines compaction and sintering into a single operation. Its unique use of uniform pressure from all directions is the key to producing materials with near-perfect density, a feat traditional methods cannot easily achieve.

The Foundation: Traditional Powder Metallurgy

To understand the significance of HIP, we must first look at the conventional two-step approach to creating parts from metal powder.

Step 1: Compaction

The first step involves compressing metal powder in a die to form a desired shape.

This initial, fragile component is known as a "green part." It has the shape of the final product but possesses very low mechanical strength, as the particles are only held together by mechanical friction.

Step 2: Sintering

The green part is then heated in a furnace to a temperature just below the metal's melting point.

This thermal energy causes the individual powder particles to bond and fuse together, a process that dramatically increases the part's strength, hardness, and density. Sintering turns the fragile green part into a functional metal component.

How HIP Transforms the Process

Hot Isostatic Pressing fundamentally changes this workflow by merging the two steps into one highly controlled, high-energy event.

Combining Heat and Pressure

Unlike the traditional method, HIP applies both thermal energy (heat) and immense pressure at the same time within a single chamber. This simultaneous application accelerates the bonding process significantly.

The Power of "Isostatic" Pressure

The defining characteristic of HIP is the use of isostatic pressure. An inert gas, such as argon, is used to apply uniform, equal pressure from all directions onto the component.

This is fundamentally different from the directional force of a mechanical press. Isostatic pressure ensures that internal pores and voids are collapsed uniformly, leading to a much more consistent density throughout the part.

The Result: A Near-Perfect Microstructure

By combining these forces, the HIP process eliminates virtually all internal porosity.

The result is a fully dense part with a homogeneous, fine-grained microstructure. This leads to exceptional material properties, including higher strength, ductility, and fatigue resistance compared to parts made by conventional sintering.

Understanding the Trade-offs

While HIP offers superior results, it is not the default choice for every application. It involves a specific set of compromises that must be considered.

Increased Cost and Complexity

The equipment required for HIP is highly specialized and expensive to operate. The process cycles are also typically longer than those for conventional sintering, adding to the overall cost and complexity of manufacturing.

When Traditional Sintering is Sufficient

For many applications where the highest possible material performance is not a critical requirement, traditional compaction and sintering remains the more economical and practical choice. The properties achieved through this method are perfectly adequate for a vast range of industrial components.

Making the Right Choice for Your Goal

Selecting the correct powder metallurgy process depends entirely on the performance demands and budget for your final component.

- If your primary focus is cost-effective production of standard components: Traditional compaction followed by sintering provides a reliable and economical solution.

- If your primary focus is achieving maximum density, strength, and fatigue life for critical applications: HIP is the essential process for creating parts that can withstand extreme service conditions.

Ultimately, choosing between these methods is a strategic decision that balances engineering requirements against manufacturing costs.

Summary Table:

| Process | Key Feature | Primary Outcome |

|---|---|---|

| Traditional Sintering | Compaction + Heat | Cost-effective parts for standard applications |

| Hot Isostatic Pressing (HIP) | Simultaneous Heat + Isostatic Gas Pressure | Fully dense parts with superior mechanical properties |

Need to produce high-performance, fully dense metal components?

The HIP process is essential for critical applications in aerospace, medical, and energy sectors where maximum material integrity is non-negotiable. KINTEK specializes in providing the advanced lab equipment and consumables needed to support research and development in powder metallurgy.

Contact our experts today to discuss how our solutions can help you achieve your material science goals.

Visual Guide

Related Products

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How big is the hot isostatic pressing market? Growth Drivers in Aerospace, Medical & 3D Printing

- What are the advantages and limitations of hot isostatic pressing? Achieve Ultimate Material Integrity

- What does HIP process do? Eliminate Porosity for Superior Material Performance

- What is the temperature of hot isostatic pressing? Achieve Full Density for Critical Components

- What is the temperature of a warm isostatic press? Achieve Optimal Densification for Your Materials