Hot Isostatic Pressing, often abbreviated as HIP, is a manufacturing process that uses a combination of elevated temperature and high-pressure inert gas to reduce or eliminate internal porosity in metals and other materials. By subjecting a component to uniform pressure from all directions at a high temperature, the process collapses internal voids, creating a fully dense, stronger, and more reliable part.

The core problem with many high-performance components, whether cast or 3D printed, is the presence of microscopic internal voids. Hot Isostatic Pressing is the definitive solution for healing these defects, transforming a part's internal structure to achieve near-perfect density and unlocking its maximum mechanical potential.

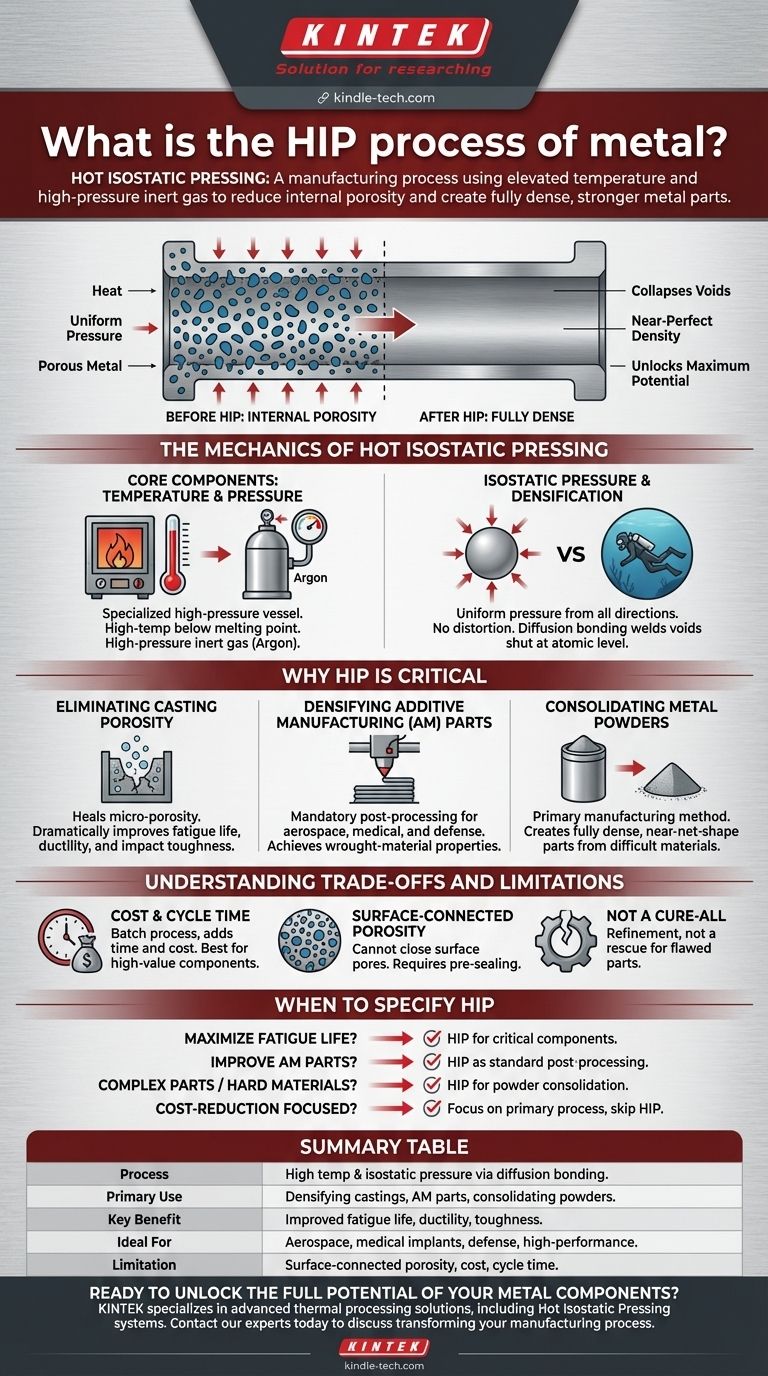

The Mechanics of Hot Isostatic Pressing

The Core Components: Temperature and Pressure

The HIP process takes place inside a specialized high-pressure vessel. This vessel contains a furnace to heat the component and a system to pump in a high-pressure, inert gas—most commonly argon.

The temperature is raised to a point below the material's melting point, making it soft and malleable enough for plastic deformation to occur.

The Principle of Isostatic Pressure

Simultaneously, the vessel is filled with inert gas, creating immense pressure. The term "isostatic" is critical; it means the pressure is applied uniformly from all directions.

This is analogous to the pressure you would feel deep in the ocean. This uniformity is key because it allows internal voids to collapse without distorting the part's external shape.

The Mechanism of Densification

The combination of high heat and immense, uniform pressure forces the material to creep and deform on a microscopic level. The walls of any internal pores or voids are pressed together.

At these temperatures, diffusion bonding occurs at the atomic level, effectively welding the voids shut and creating a strong, homogeneous metallurgical bond.

Why HIP is a Critical Process

Eliminating Casting Porosity

Even the best metal castings contain some level of micro-porosity from trapped gas or shrinkage during solidification. These tiny voids are stress concentrators and the primary initiation sites for fatigue cracks.

HIP densifies the casting, healing these pores and dramatically improving fatigue life, ductility, and impact toughness.

Densifying Additive Manufacturing (AM) Parts

Metal 3D-printed parts, made via processes like laser powder bed fusion, can also have internal defects such as gas porosity or lack-of-fusion voids.

For critical applications in aerospace, medical implants, and defense, HIP is often a mandatory post-processing step to ensure the printed part achieves properties equivalent to or better than traditional wrought materials.

Consolidating Metal Powders

HIP can also be used as a primary manufacturing method. In this application, metal powders are sealed in a shaped canister or "can" under vacuum.

The HIP cycle then consolidates the powder into a fully dense, solid, near-net-shape part. This is highly effective for creating components from materials that are difficult to machine or forge.

Understanding the Trade-offs and Limitations

Cost and Cycle Time

HIP is a batch process that adds significant cost and lead time to the manufacturing workflow. A single HIP cycle can take many hours. For this reason, it is typically reserved for high-value or performance-critical components.

Surface-Connected Porosity

A critical limitation is that HIP cannot close pores that are open to the surface. The high-pressure gas will simply enter the void, equalizing the pressure and preventing it from collapsing. Parts with surface porosity may need to be sealed via welding or another method before the HIP process.

Not a Cure-All for Gross Defects

HIP is exceptionally effective at healing microscopic voids. However, it cannot fix large-scale defects, chemistry issues, or problems caused by poor initial casting or printing practices. It is a refinement process, not a rescue mission for a fundamentally flawed part.

When to Specify the HIP Process

To make the right decision, you must align the process with your component's end-use requirements.

- If your primary focus is maximizing fatigue life and reliability in critical components: HIP is an essential step to eliminate the micro-voids that initiate cracks under cyclic loading.

- If your primary focus is improving the mechanical properties of metal 3D-printed parts: Use HIP as a standard post-processing step to achieve full density and unlock performance comparable to wrought alloys.

- If your primary focus is creating complex parts from difficult-to-work materials: Consider HIP for powder consolidation to produce near-net-shape components that minimize machining.

- If your primary focus is cost-reduction for non-critical, low-stress applications: HIP is likely an unnecessary expense; focus instead on optimizing your primary manufacturing process.

By understanding HIP as a powerful tool for achieving material perfection, you can elevate your components from merely functional to truly exceptional.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | High temperature and isostatic gas pressure eliminate internal porosity via diffusion bonding. |

| Primary Use | Densifying castings, metal 3D-printed parts, and consolidating metal powders. |

| Key Benefit | Dramatically improves fatigue life, ductility, and impact toughness. |

| Ideal For | Aerospace, medical implants, defense, and other high-performance applications. |

| Limitation | Cannot heal surface-connected porosity; adds cost and cycle time. |

Ready to unlock the full potential of your metal components?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing systems and consumables. Whether you are densifying critical aerospace castings or ensuring the reliability of 3D-printed medical implants, our expertise and equipment help you achieve near-perfect part density and superior mechanical properties.

Contact our experts today to discuss how HIP can transform your manufacturing process and deliver stronger, more reliable parts.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What is the HIP material process? Achieve Near-Perfect Density and Reliability