At its core, the hot isostatic pressing (HIP) cycle is a controlled manufacturing process that subjects a component to both elevated temperature and high, uniform pressure simultaneously. Inside a sealed chamber, an inert gas like argon is used to apply this pressure evenly from all directions, while the temperature is raised to a point where the material becomes plastic. This combination effectively closes and welds shut internal voids, pores, or defects within the material.

The central purpose of the HIP cycle is not to form a part, but to perfect it. It is a healing process that uses simultaneous heat and uniform pressure to eliminate internal porosity, thereby dramatically improving a component's mechanical properties, density, and reliability.

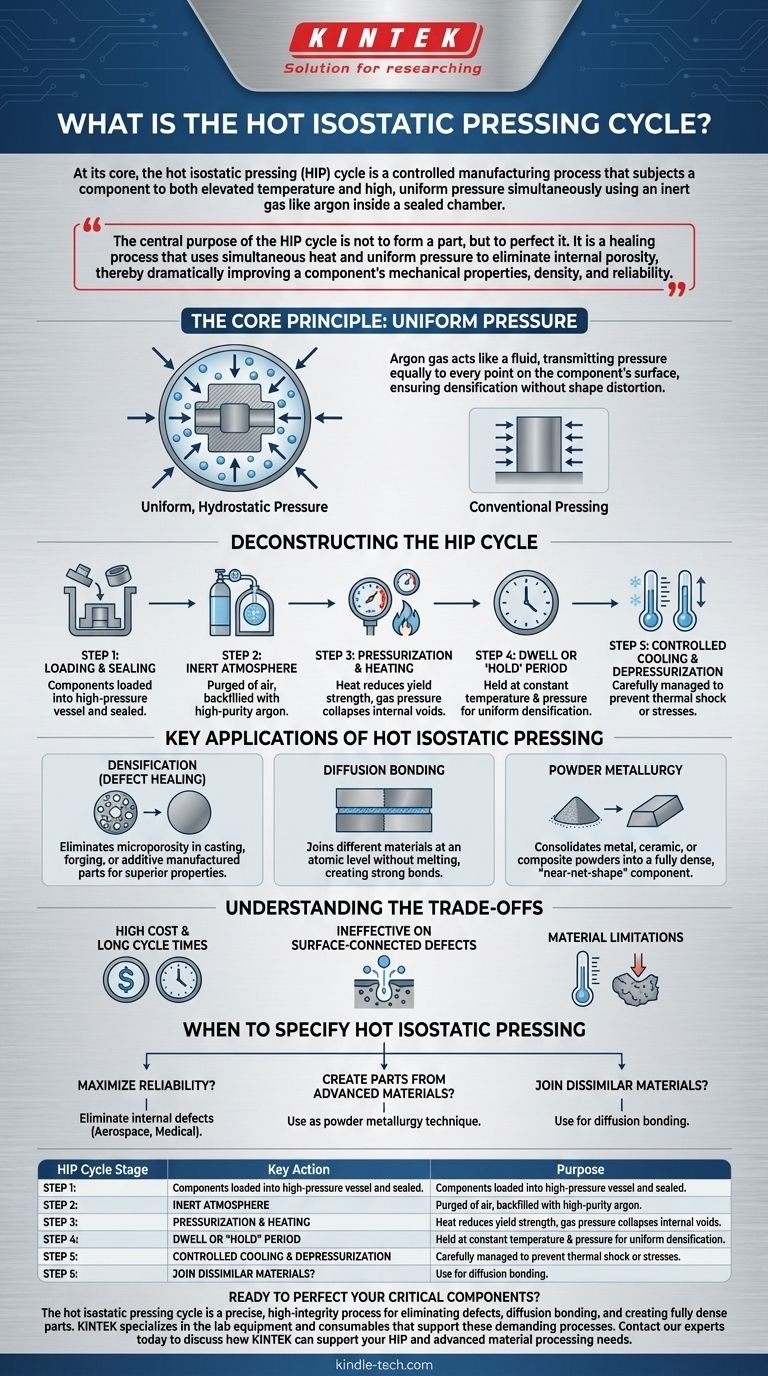

Deconstructing the HIP Cycle

The process is meticulously controlled by computers to ensure repeatable and precise results. While parameters vary based on the material and desired outcome, the fundamental stages remain consistent.

Step 1: Loading and Sealing

Components are loaded into the HIP unit's high-pressure vessel. Once the parts are in place, the vessel is sealed to create a contained environment.

Step 2: Creating an Inert Atmosphere

The chamber is purged of air and backfilled with a high-purity inert gas, almost always argon. This prevents the material from oxidizing or reacting chemically at the high processing temperatures.

Step 3: Simultaneous Pressurization and Heating

The core of the process begins as the temperature and pressure are ramped up in a controlled manner. The heat reduces the material's yield strength, making it soft and malleable, while the immense gas pressure collapses internal voids.

Step 4: The Dwell or "Hold" Period

Once the target temperature and pressure are reached, they are held constant for a specific duration. This "dwell time" ensures the temperature is uniform throughout the component and allows for complete densification and the diffusion bonding of internal surfaces.

Step 5: Controlled Cooling and Depressurization

After the dwell time, the vessel is cooled and the pressure is released. This final phase is carefully managed to prevent thermal shock or the introduction of new internal stresses into the now-densified part.

The Core Principle: Uniform Pressure

The effectiveness of isostatic pressing lies in its use of uniform, hydrostatic pressure. The argon gas acts like a fluid, transmitting pressure equally to every point on the component's surface.

This is fundamentally different from conventional pressing, which applies force from one or two directions. The all-sided pressure ensures that a part becomes denser without distorting its shape, closing pores uniformly throughout its volume.

Key Applications of Hot Isostatic Pressing

The HIP process is chosen based on the specific need of the product. It is broadly used for three primary applications.

Densification (Defect Healing)

This is the most common use. HIP is applied to components made by casting, forging, or additive manufacturing (3D printing) to eliminate microporosity. This transforms a standard part into one with superior fatigue life, strength, and toughness.

Diffusion Bonding

HIP can be used to join two or more different materials together at an atomic level without melting. The heat and pressure cause atoms from each surface to diffuse into the other, creating a bond that is as strong as the parent materials themselves.

Powder Metallurgy

The process can consolidate metal, ceramic, or composite powders into a fully dense, solid part. The powder is sealed in a flexible mold or canister, and the HIP cycle compacts it into a "near-net-shape" component with a uniform, fine-grained microstructure.

Understanding the Trade-offs

While powerful, the HIP process involves important considerations that make it suitable for specific, high-value applications.

High Cost and Long Cycle Times

HIP units are significant capital investments, and the cycles themselves can last for many hours. This makes the process more expensive than conventional heat treatments.

Ineffective on Surface-Connected Defects

The process relies on gas pressure to close internal voids. If a pore is open to the surface of the part, the gas will simply enter the pore and pressurize it from within, preventing it from collapsing.

Material Limitations

The material being processed must be able to withstand the high temperatures required for densification without melting or degrading. This requires careful selection of process parameters for each specific alloy or material.

When to Specify Hot Isostatic Pressing

Your decision to use HIP should be driven by the end-goal for your component.

- If your primary focus is maximizing reliability in critical components: Use HIP to eliminate internal defects in castings or 3D-printed parts, especially for aerospace or medical applications.

- If your primary focus is creating parts from advanced materials: Use HIP as a powder metallurgy technique to form fully dense components from specialized alloys or ceramics that are difficult to process otherwise.

- If your primary focus is joining dissimilar materials without a weak weld joint: Use HIP for diffusion bonding to create high-integrity bimetallic or metal-ceramic components.

Ultimately, hot isostatic pressing is a powerful tool for achieving the highest possible material integrity when performance cannot be compromised.

Summary Table:

| HIP Cycle Stage | Key Action | Purpose |

|---|---|---|

| Loading & Sealing | Place parts in vessel and seal | Create a contained environment |

| Inert Atmosphere | Purge air, backfill with argon | Prevent oxidation at high temperatures |

| Pressurization & Heating | Ramp up gas pressure and temperature | Make material malleable, collapse voids |

| Dwell Period | Hold target temperature and pressure | Ensure uniform densification and bonding |

| Cooling & Depressurization | Controlled cool-down and pressure release | Prevent thermal shock and new stresses |

Ready to perfect your critical components?

The hot isostatic pressing cycle is a precise, high-integrity process for eliminating internal defects, diffusion bonding dissimilar materials, and creating fully dense parts from powders. For labs and manufacturers in aerospace, medical, and advanced materials, achieving this level of performance is non-negotiable.

KINTEK specializes in the lab equipment and consumables that support these demanding processes. Whether you are researching material behavior or scaling up production, we provide the reliable solutions you need.

Contact our experts today to discuss how KINTEK can support your HIP and advanced material processing needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the working principle of hot isostatic pressing? Unlock Superior Material Density & Performance

- What role does a warm isostatic laminator play in reducing porosity? Achieve High-Density Solid-State Battery Electrodes

- What is the HIP process of casting? Transform Castings into High-Performance Components

- When was hot isostatic pressing invented? The 1955 Breakthrough for Superior Material Integrity

- What is the application of isostatic pressing? Achieve Uniform Density in High-Performance Components

- How does Hot Isostatic Press (HIP) enhance Si3N4 and h-BN ceramics? Achieving Full Density and Isotropy

- Why is a SUS304 stainless steel capsule used to encapsulate IN718 powder? Key Benefits for HIP Processing

- What are the conditions for hot isostatic pressing? Unlock Maximum Material Density