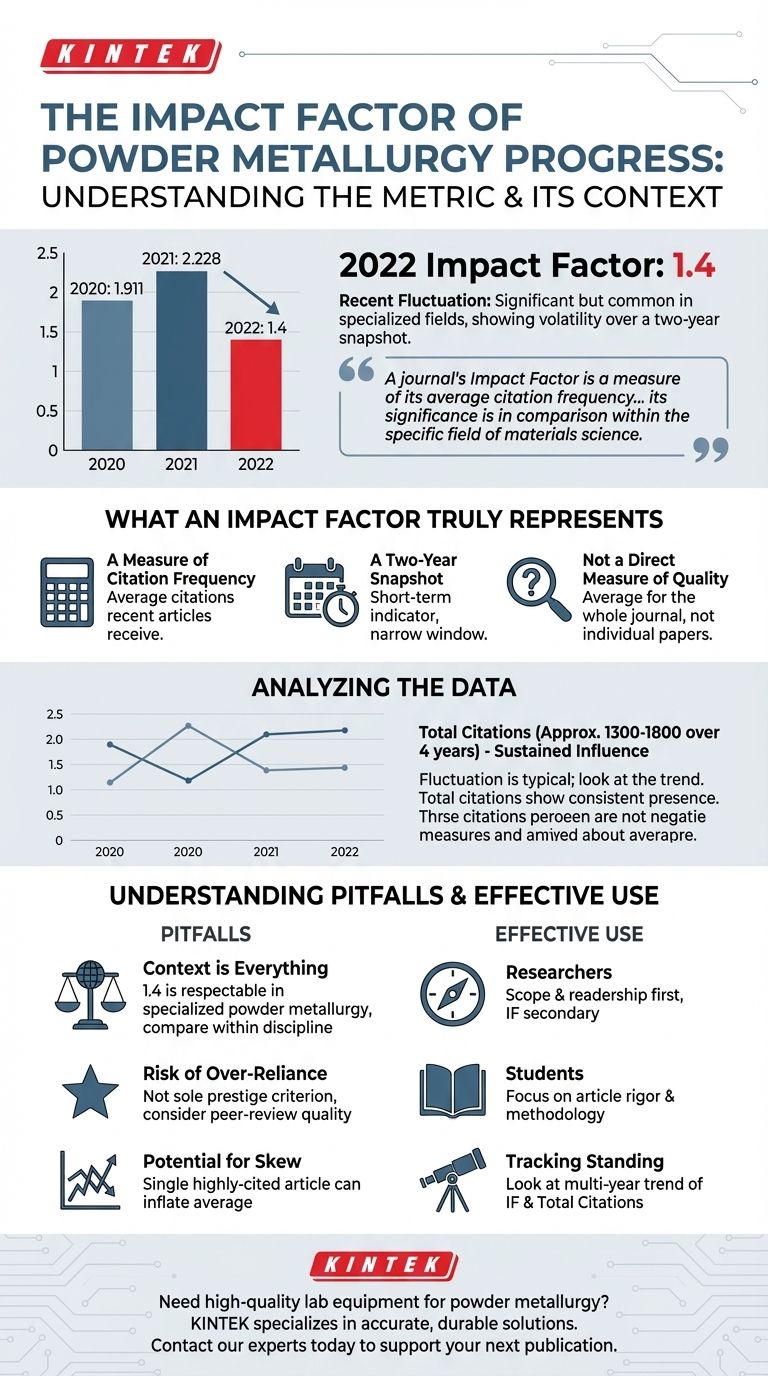

Based on the most recent available data from 2022, the Impact Factor for the journal Powder Metallurgy Progress is 1.4. This metric has shown notable fluctuation in recent years, with an Impact Factor of 2.228 in 2021 and 1.911 in 2020.

A journal's Impact Factor is a measure of its average citation frequency over a two-year period. Its true significance is not the absolute number, but how that number compares to other journals within the specific and specialized field of materials science.

What an Impact Factor Truly Represents

An Impact Factor (IF) is one of the most common, yet often misunderstood, metrics in academic publishing. To use it effectively, you must understand what it is actually measuring.

A Measure of Citation Frequency

The Impact Factor is a simple calculation. It divides the number of times articles from a journal were cited in a given year by the total number of citable articles the journal published in the two preceding years.

In essence, it reflects the average number of citations recent articles in that journal receive.

A Two-Year Snapshot

The IF calculation is based on a narrow two-year window. This makes it a short-term indicator of a journal's influence.

A journal's IF can change significantly from one year to the next based on the citation performance of a relatively small number of papers.

Not a Direct Measure of Quality

A higher Impact Factor does not automatically mean every article in the journal is of high quality, nor does a lower IF mean an article is poor.

It is an average for the journal as a whole, not a score for any individual paper.

Analyzing the Data for Powder Metallurgy Progress

The provided data shows a common pattern for specialized academic journals: fluctuation. Understanding the trend is more useful than focusing on a single year's number.

The Recent Fluctuation

The drop from 2.228 in 2021 to 1.4 in 2022 is significant but not necessarily alarming. This can easily be caused by one or two highly-cited articles from 2019 or 2020 falling out of the calculation window for the 2022 score.

This volatility is a key characteristic of the metric and highlights the danger of judging a journal based on a single year's data.

The Role of Total Citations

While the Impact Factor has fluctuated, the Total Cites have remained relatively stable, hovering between approximately 1300 and 1800 over the four-year period.

This suggests that the journal's broader catalog of work maintains a consistent and established presence within its research community, even if the specific IF metric varies year to year.

Understanding the Pitfalls of This Metric

Relying solely on Impact Factor can be misleading. Its value is entirely dependent on context, and it comes with inherent limitations.

Context is Everything

An Impact Factor of 1.4 might be considered low in a broad, fast-moving field like general medicine. However, in a highly specialized field like powder metallurgy, this can be a perfectly respectable figure.

The only valid use of IF is to compare journals within the same specific discipline.

The Risk of Over-Reliance

Using Impact Factor as the sole criterion for a journal's prestige is a common mistake. Other factors, such as the quality of its peer-review process, the relevance of its scope to your work, and its reputation among peers, are equally important.

Potential for Skew

Because the IF is an average, it can be easily skewed. A single, highly-cited review article can dramatically inflate a journal's Impact Factor for a year or two, masking the typical citation rate of its other research articles.

How to Use This Information Effectively

The key is to treat the Impact Factor as one data point among many, not as a final verdict.

- If you are a researcher choosing where to publish: Consider the journal's specific scope and readership first. The IF is a secondary factor for comparing journals that are otherwise a good fit for your work.

- If you are a student evaluating a source: Focus on the quality and methodology of the individual article itself. The journal's IF is far less important than the rigor of the research you are reading.

- If you are tracking the journal's standing: Look at the multi-year trend in both Impact Factor and Total Citations to get a more balanced view of its sustained influence in the field.

Ultimately, the Impact Factor is a tool for relative comparison, not a definitive judgment of quality; its true meaning is only found within the context of its specific field.

Summary Table:

| Year | Impact Factor |

|---|---|

| 2022 | 1.4 |

| 2021 | 2.228 |

| 2020 | 1.911 |

Need high-quality, reliable equipment for your powder metallurgy research? The findings in journals like Powder Metallurgy Progress depend on precise and durable lab equipment. KINTEK specializes in supplying the laboratory equipment and consumables that researchers in materials science rely on for accurate, reproducible results. Contact our experts today to discuss how our solutions can support your next groundbreaking publication.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Boron Nitride (BN) Crucible for Phosphorous Powder Sintered

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What are the advantages of a vacuum hot pressing furnace? Achieve high-density NTC ceramics with superior stability.

- What are the advantages of using a vacuum hot pressing sintering furnace? Superior Density for Nanocrystalline Fe3Al

- What are the advantages of using a vacuum hot pressing furnace? Achieve 98.9% Density in Al2O3-TiC Laminated Ceramics