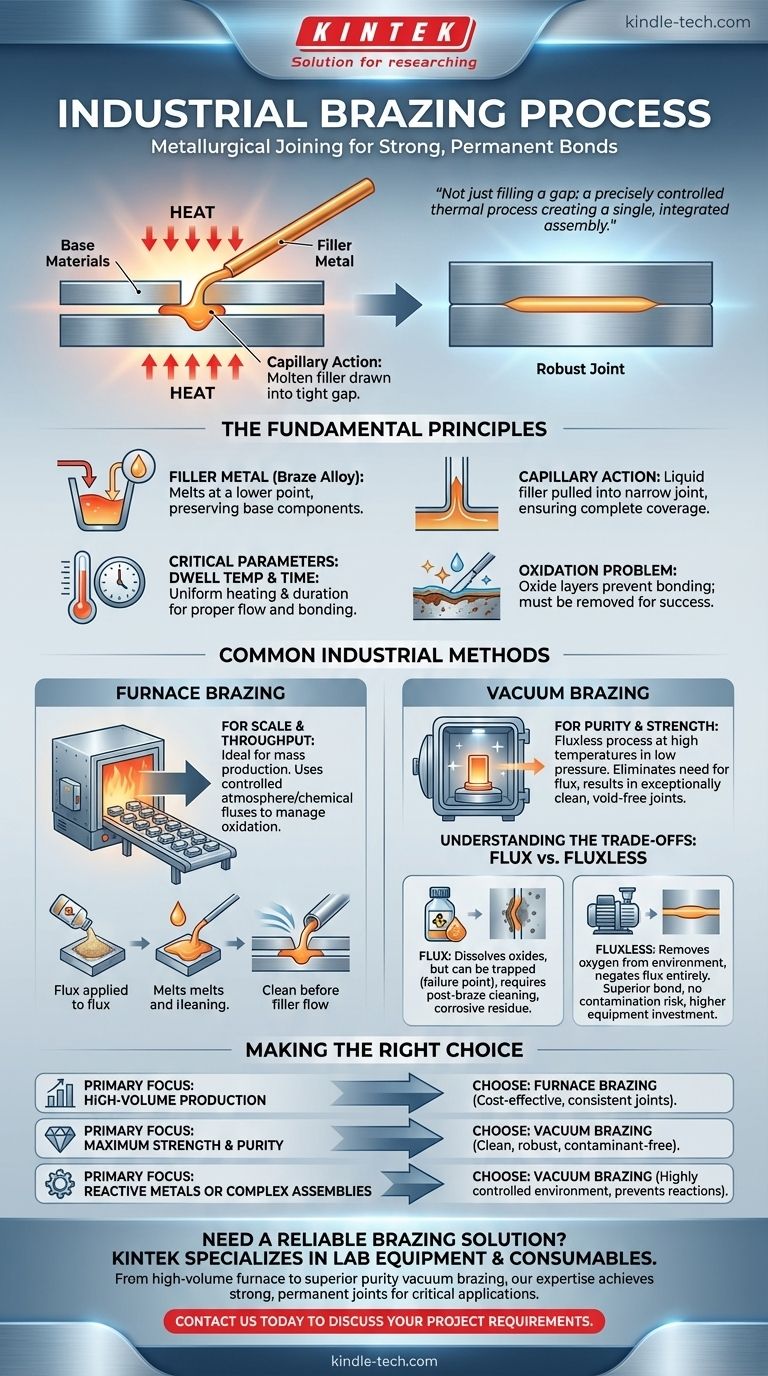

Industrial brazing is a metallurgical joining process used to create strong, permanent bonds between two or more material components. It involves heating the entire assembly to a temperature below the melting point of the base materials but above the melting point of a dissimilar filler metal. This molten filler is drawn into the tight gap between the parts via capillary action and, upon cooling, solidifies to form a robust joint.

The core principle of industrial brazing is not merely filling a gap with molten metal. It is a precisely controlled thermal process where the environment—such as a furnace atmosphere or a high vacuum—is managed to remove surface oxides and allow a filler metal to metallurgically bond with the base materials, creating a single, integrated assembly.

The Fundamental Principles of Brazing

The Role of Filler Metal

The brazing process relies on a filler metal (also called a braze alloy) that has a lower melting point than the base materials being joined. When the assembly reaches the correct temperature, only the filler metal melts, preserving the integrity of the components.

The Importance of Capillary Action

A properly designed brazed joint has a very small, uniform gap between the components. When the filler metal becomes liquid, capillary action—the tendency of a liquid to be drawn into a narrow space—pulls the molten alloy into the entire joint, ensuring complete coverage and a strong bond.

Critical Parameters: Temperature and Time

The success of any brazing operation depends on two essential parameters: dwell temperature and time. The assembly must be heated uniformly to a specific temperature that allows the filler to melt and flow freely. It must then be held at that temperature for a sufficient duration for the capillary action to complete before cooling.

The Problem of Oxidation

Nearly all metals form an oxide layer on their surface, especially when heated. This layer acts as a barrier, preventing the molten filler metal from wetting the base material and forming a proper bond. A critical function of any brazing process is to remove this oxide layer.

Common Industrial Brazing Methods

Furnace Brazing: For Scale and Throughput

In furnace brazing, the entire assembly is placed inside a furnace with a controlled atmosphere and heated. This method is highly efficient for mass production, as it allows for the simultaneous creation of thousands of joints in a single heating cycle.

Atmospheric furnaces often use chemical fluxes or specific gas mixtures to manage oxidation. The process follows a precise thermal profile where the flux melts first to clean the surfaces before the filler metal melts and flows.

Vacuum Brazing: For Purity and Strength

Vacuum brazing is a fluxless process performed at high temperatures within a low-pressure vacuum chamber, typically in the 10⁻⁵ to 10⁻⁶ torr range. Heating metals in a vacuum effectively removes surface oxides and prevents re-oxidation from occurring.

This method eliminates the need for chemical flux, resulting in exceptionally clean, strong, and void-free joints. It is the preferred method for joining reactive metals and for high-performance applications in aerospace, medical, and electronics industries.

Understanding the Trade-offs: Flux vs. Fluxless

Flux-Based Brazing

Flux is a chemical compound applied to the joint area before heating. Its purpose is to dissolve existing oxides, protect the surfaces from re-oxidation during the heating cycle, and help the filler metal flow.

While effective, flux can become trapped within the joint, creating a potential failure point. Flux residues are also often corrosive and require thorough post-braze cleaning, adding an extra step and cost to the process.

Fluxless (Vacuum) Brazing

By removing oxygen from the environment, vacuum brazing eliminates the root cause of oxidation. This negates the need for chemical flux entirely.

The result is a superior metallurgical bond free from the risk of flux entrapment or contamination. The primary trade-off is the higher initial investment in complex vacuum furnace equipment and longer cycle times compared to some atmospheric furnace methods.

Making the Right Choice for Your Goal

The ideal brazing method depends on your project's specific requirements for scale, material compatibility, and final joint quality.

- If your primary focus is high-volume production: Furnace brazing is often the most cost-effective solution for creating many consistent joints simultaneously.

- If your primary focus is maximum joint strength and purity: Vacuum brazing is the superior choice for creating clean, robust metallurgical bonds free from contaminants, ideal for critical applications.

- If you are joining reactive metals or complex assemblies: Vacuum brazing provides the highly controlled, clean environment necessary to prevent unwanted chemical reactions and ensure complete joint penetration.

By understanding these core principles, you can select the process that ensures the integrity and performance of your final product.

Summary Table:

| Brazing Method | Key Characteristic | Ideal Application |

|---|---|---|

| Furnace Brazing | High-volume production, uses controlled atmosphere/flux | Mass production of consistent joints |

| Vacuum Brazing | Maximum strength & purity, fluxless process | Aerospace, medical, electronics, reactive metals |

Need a reliable brazing solution for your laboratory or production line? KINTEK specializes in lab equipment and consumables, including brazing systems designed for precision and performance. Whether you require high-volume furnace brazing or the superior purity of vacuum brazing, our expertise can help you achieve strong, permanent joints for your critical applications. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond

- How is the greatest joint strength obtained in brazing? Master the 3 Keys to Superior Metallurgical Bonds

- What is the most important factor influencing the strength of the brazed joint? Master Joint Clearance for Maximum Strength

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints