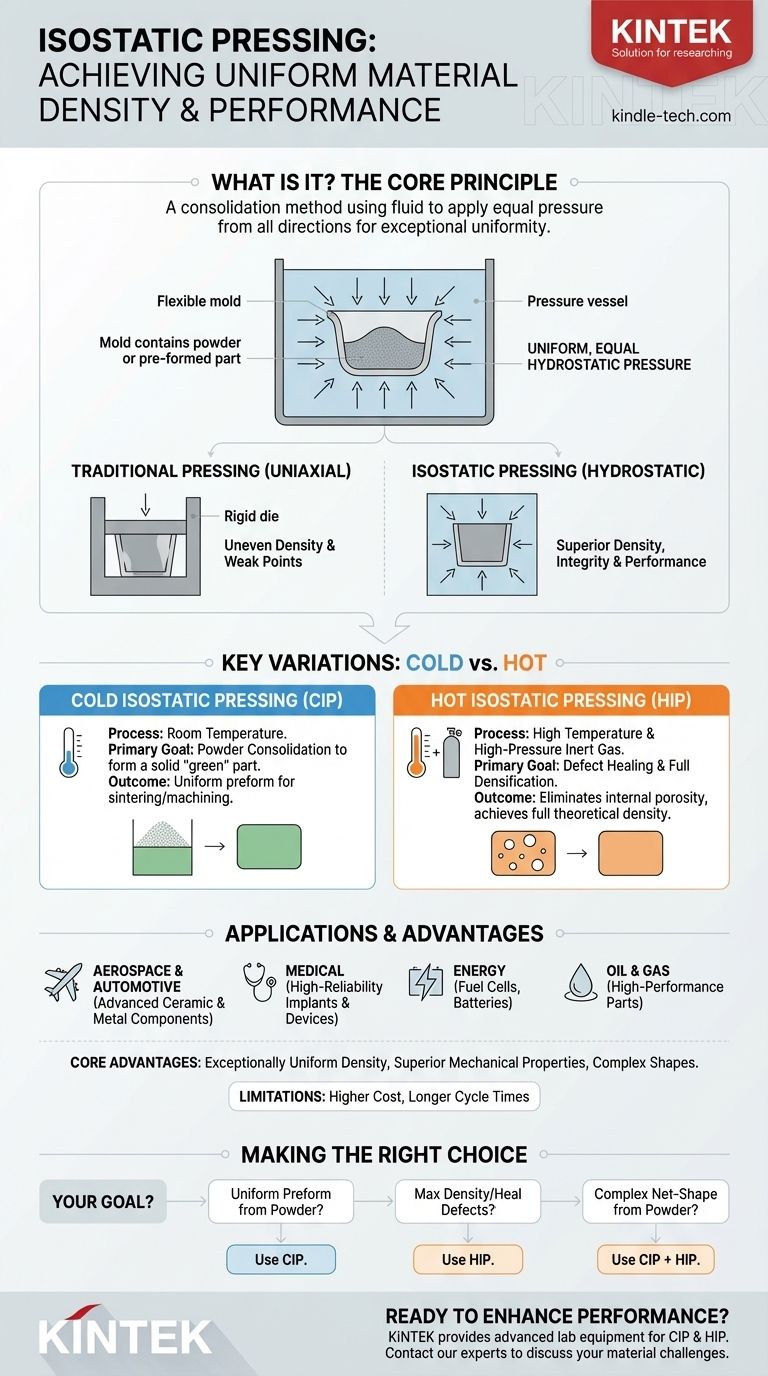

At its core, isostatic pressing is a material consolidation method that uses a fluid to apply uniform, equal pressure from all directions onto a workpiece. The part, typically powder in a flexible mold or a pre-formed solid component, is submerged in a pressure vessel, which is then pressurized to compact the material or eliminate internal defects with exceptional uniformity.

Traditional pressing methods often create weak points and density variations within a part. Isostatic pressing solves this fundamental problem by applying hydrostatic pressure equally from all sides, resulting in components with superior density, integrity, and performance.

The Fundamental Principle: Uniform Compaction

Traditional manufacturing methods that press materials from one or two directions often struggle with consistency. Isostatic pressing was developed to overcome these limitations.

The Problem with Uniaxial Pressing

When pressing a powder in a rigid die from only one direction (uniaxially), friction between the powder and the die walls prevents pressure from being transmitted evenly. This results in significant density variations, with the areas farthest from the punch being less dense and mechanically weaker.

The Isostatic Solution: Hydrostatic Pressure

Isostatic pressing places the material (often a powder sealed in a flexible, elastic mold) into a pressure vessel. A liquid or gas medium is then used to apply immense pressure.

Crucially, this pressure is hydrostatic, meaning it is equal in all directions at any given point. The flexible mold deforms and transmits this uniform pressure directly to the material inside, minimizing internal friction and ensuring consistent compaction throughout the entire volume.

The Result: Superior Material Integrity

This uniform compaction produces parts with a highly consistent density and microstructure. This method is used for two primary goals:

- Powder Consolidation: To form a solid "green" part from metal, ceramic, or composite powders.

- Defect Healing: To eliminate internal voids and porosity in pre-existing parts, such as metal castings, to achieve full theoretical density.

Key Variations: Hot vs. Cold Isostatic Pressing

The process is generally categorized by the temperature at which it is performed. The choice between them depends entirely on the desired outcome for the material.

Cold Isostatic Pressing (CIP)

CIP is performed at or near room temperature. Its primary purpose is to compact powders into a solid shape with sufficient strength for handling and subsequent processing, like sintering or machining. It is the foundational step for creating a uniform preform.

Hot Isostatic Pressing (HIP)

HIP subjects a part to both elevated temperature and high-pressure inert gas (typically argon) simultaneously. This process is used on pre-formed parts or powders encapsulated in a solid container.

The combination of heat and pressure allows for plastic deformation and atomic diffusion, effectively welding shut and eliminating any internal porosity. This creates a fully dense component with dramatically improved mechanical properties. The process is precisely controlled and ends with a managed cool-down period.

Understanding the Applications and Trade-offs

Isostatic pressing is a powerful but specialized technique. Understanding its advantages and limitations is key to knowing when to apply it.

Core Advantages

The primary benefit is the creation of parts with exceptionally uniform density. This leads to predictable and superior mechanical properties, such as strength and fatigue resistance. It also allows for the manufacturing of more complex shapes than is possible with traditional die compaction.

Common Applications Across Industries

Because of its unique benefits, isostatic pressing is critical in high-performance sectors:

- Aerospace & Automotive: Manufacturing advanced ceramic and metal components.

- Medical: Creating high-reliability implants and devices.

- Energy: Producing components for fuel cells and improving lithium-ion batteries.

- Oil & Gas: Making high-performance parts that can withstand extreme environments.

- Other: Processing materials for pharmaceuticals, nuclear fuel, and advanced electronics.

Limitations to Consider

The main trade-offs are cost and cycle time. The equipment required for both CIP and especially HIP is complex and expensive. Process cycles can be long, particularly for the heating and cooling phases of HIP, making it less suitable for high-volume, low-cost manufacturing.

Making the Right Choice for Your Goal

Your specific objective determines which isostatic method is appropriate for your project.

- If your primary focus is creating a uniform preform from powder: Use Cold Isostatic Pressing (CIP) to achieve consistent "green" density before further sintering or machining.

- If your primary focus is achieving maximum density and eliminating defects in a critical part: Use Hot Isostatic Pressing (HIP) to heal internal porosity in castings or fully consolidate sintered components.

- If your primary focus is manufacturing complex net-shape parts from powder: A combination of CIP to form the shape and HIP to densify it is a common and effective strategy.

By understanding these principles, you can leverage isostatic pressing to create materials and components with unparalleled uniformity and performance.

Summary Table:

| Process | Temperature | Primary Goal | Key Applications |

|---|---|---|---|

| Cold Isostatic Pressing (CIP) | Room Temperature | Powder Consolidation (Forming a "green" part) | Creating uniform preforms for sintering |

| Hot Isostatic Pressing (HIP) | High Temperature | Defect Healing & Full Densification | Eliminating porosity in castings, advanced components |

Ready to enhance your materials' performance with uniform density?

KINTEK specializes in providing advanced lab equipment and consumables for materials processing. Whether your project requires Cold Isostatic Pressing (CIP) for powder consolidation or Hot Isostatic Pressing (HIP) for achieving maximum density, our solutions are designed to meet the rigorous demands of laboratories in aerospace, medical, energy, and other high-tech sectors.

Contact our experts today to discuss how isostatic pressing can solve your specific material challenges and deliver components with superior integrity and performance.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components