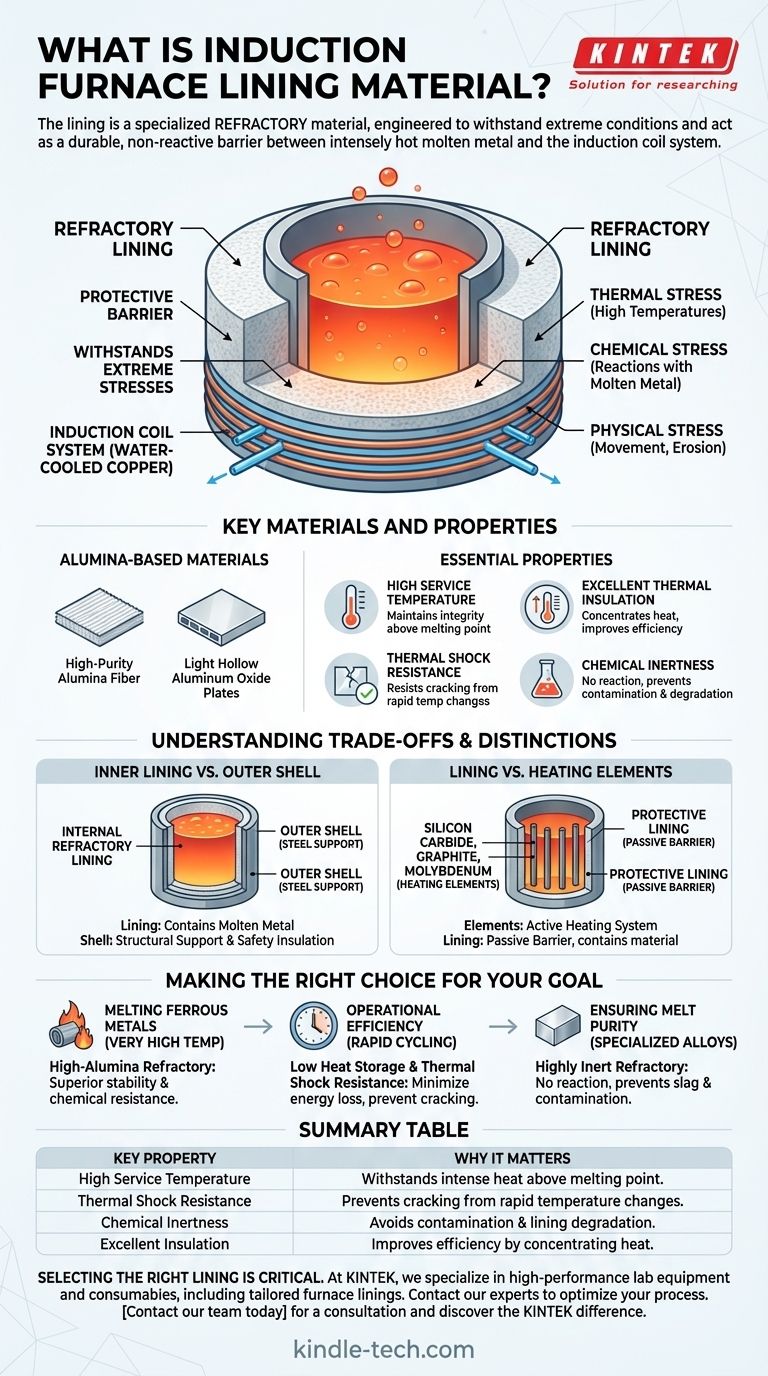

In an induction furnace, the lining is made from a specialized category of materials known as refractories. These are engineered materials, such as high-purity alumina or other refractory plates, designed to withstand extreme conditions. The lining's most critical function is to act as a durable, non-reactive barrier between the intensely hot molten metal and the furnace's vital induction coil system.

The choice of an induction furnace lining is not about simple insulation. It is a critical engineering decision to select a specific refractory material that can endure immense thermal, chemical, and physical stress to protect the core components of the furnace and ensure the purity of the melt.

The Core Function of the Refractory Lining

The lining is arguably one of the most important components in an induction furnace, serving as the first and last line of defense during operation. Its performance directly impacts safety, efficiency, and product quality.

A Protective Barrier

The primary role of the lining is to contain the molten metal and protect the induction coil. Direct contact between the molten charge and the water-cooled copper coil would be catastrophic, and the refractory lining prevents this.

Withstanding Extreme Stresses

The lining material is constantly subjected to a combination of forces. It must endure intense thermal stress from high temperatures, chemical stress from potential reactions with the molten metal, and physical stress from the movement and erosion of the charge.

Key Materials and Their Properties

While the general term is "refractory," specific material choices are based on the intended application, particularly the type of metal being melted (ferrous or non-ferrous).

Alumina-Based Materials

For many applications, materials like high-purity alumina fiber and light hollow aluminum oxide plates are used. These are valued for their high performance and reliability under heat.

Essential Material Properties

The effectiveness of a lining is defined by a few key characteristics:

- High Service Temperature: The material must maintain its structural integrity well above the melting point of the metal.

- Excellent Thermal Insulation: Good insulation keeps the heat concentrated in the melt, improving energy efficiency and protecting external components.

- Thermal Shock Resistance: The lining must resist cracking or spalling when subjected to the rapid temperature changes inherent in furnace operation.

- Chemical Inertness: A quality lining will not react with the molten metal. This prevents contamination of the final product and avoids degradation of the lining itself, a common cause of slag.

Understanding the Trade-offs and Distinctions

It is easy to confuse the different components of a furnace system. Clarifying their distinct roles is essential for understanding the overall design.

Inner Lining vs. Outer Shell

The internal refractory lining is completely different from the furnace's outer shell. The shell is typically made of high-quality steel and is designed for structural support, while its own insulation layer is meant to keep the exterior safe to the touch.

Lining vs. Heating Elements

In some furnace designs, materials like silicon carbide rods, graphite, or molybdenum strips are used. It is important to recognize that these are typically heating elements, not the protective lining that contains the molten material. The lining is the passive barrier, while the elements are part of the active heating system.

Making the Right Choice for Your Goal

The selection of a lining material is dictated by the specific operational goal. The properties of the refractory must be matched to the demands of the process.

- If your primary focus is melting ferrous metals at very high temperatures: You require a high-alumina refractory known for its superior high-temperature stability and chemical resistance.

- If your primary focus is operational efficiency and rapid cycling: A lining with low heat storage capacity and excellent thermal shock resistance is crucial to minimize energy loss and prevent cracking.

- If your primary focus is ensuring melt purity for specialized alloys: The key is selecting a highly inert refractory that will not react with your specific metal charge or contribute to slag formation.

Ultimately, the right lining material is a carefully engineered choice that directly impacts the safety, efficiency, and quality of your melting operations.

Summary Table:

| Key Property | Why It Matters for the Lining |

|---|---|

| High Service Temperature | Withstands intense heat well above the metal's melting point. |

| Thermal Shock Resistance | Prevents cracking from rapid temperature changes during operation. |

| Chemical Inertness | Avoids contaminating the melt and prevents lining degradation. |

| Excellent Insulation | Improves energy efficiency by concentrating heat in the melt. |

Selecting the right refractory lining is critical for your furnace's performance and safety. At KINTEK, we specialize in high-performance lab equipment and consumables, including furnace linings tailored for your specific application—whether you're melting ferrous metals, prioritizing efficiency, or ensuring ultimate melt purity. Our experts can help you choose the ideal material to protect your investment and optimize your process. Contact our team today for a consultation and discover the KINTEK difference in reliability and support.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Lab-Scale Vacuum Induction Melting Furnace

People Also Ask

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What are the benefits of a tube furnace? Achieve Superior Temperature & Atmosphere Control

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere