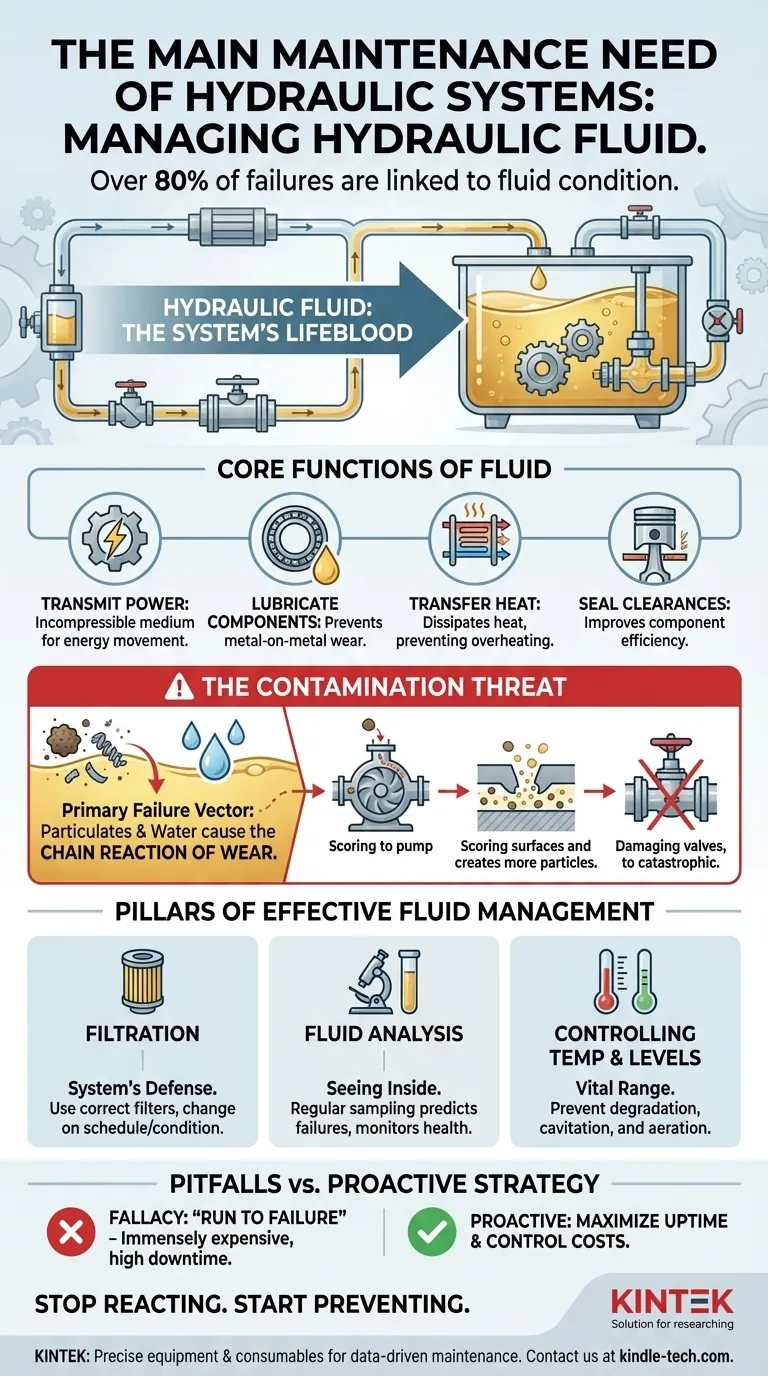

The single most critical maintenance need of any hydraulic system is managing the hydraulic fluid. While components like pumps, valves, and seals require attention, the vast majority of hydraulic failures—often cited as over 80%—can be traced directly back to the condition of the fluid itself. Proper fluid management is the foundation of a reliable system.

Hydraulic systems are not primarily mechanical systems that happen to use fluid; they are fluid systems that use mechanical components to do work. Therefore, the core maintenance strategy must shift from reacting to broken parts to proactively preserving the health of the hydraulic fluid.

Why Hydraulic Fluid is the System's Lifeblood

Understanding the multiple roles of hydraulic fluid is key to appreciating why its maintenance is paramount. It is far more than just a medium for transmitting power.

The Four Core Functions of Fluid

Hydraulic fluid is engineered to perform four critical jobs simultaneously. A failure in any one of these functions compromises the entire system.

- Transmit Power: This is its primary purpose, acting as a nearly incompressible medium to move energy from the pump to the actuators.

- Lubricate Components: The fluid creates a vital film between moving parts inside pumps, motors, and valves, preventing metal-on-metal contact and wear.

- Transfer Heat: As the fluid circulates, it carries heat away from components and dissipates it through a reservoir or cooler, preventing overheating.

- Seal Clearances: The fluid helps form a seal in the microscopic clearances between parts, improving the efficiency of the components.

Contamination: The Primary Failure Vector

Contamination is the introduction of any foreign substance into the fluid. These contaminants directly attack the fluid's ability to perform its core functions and are the leading cause of component damage.

The most common and destructive contaminants are particulate matter (dirt, metal shavings) and water. Even microscopic particles can cause a chain reaction of wear, generating more particles and leading to catastrophic failure.

The Chain Reaction of Wear

Imagine a tiny grain of sand circulating in your hydraulic system. It gets caught in the tight tolerances of a hydraulic pump, scoring the internal surfaces. This scoring not only reduces the pump's efficiency but also creates new, sharp metal particles.

These new particles then travel downstream, damaging valve spools, clogging orifices, and degrading cylinder seals. This process, known as the chain reaction of wear, is why a seemingly minor contamination issue can quickly destroy thousands of dollars in components.

The Pillars of Effective Fluid Management

A proactive maintenance strategy is built on a few core principles designed to keep the fluid clean, cool, and free of contaminants.

Filtration: Your System's Defense

Filters are not optional accessories; they are essential for removing harmful particles. A robust filtration plan involves using the correct filters in the right locations (pressure, return, and offline loops) and, most importantly, changing them based on a schedule or condition indicator, not just when a failure occurs.

Fluid Analysis: Seeing Inside the System

Regular oil sampling and analysis is the equivalent of a blood test for your hydraulic system. It provides a precise snapshot of the fluid's condition.

This analysis can identify the type and quantity of contaminants, detect water presence, and measure the breakdown of the fluid's chemical properties (like viscosity and additive packages). This data allows you to predict failures and take corrective action long before a breakdown.

Controlling Temperature and Levels

Always ensure the system operates within its designed temperature range. Excessive heat rapidly degrades hydraulic fluid and destroys seals.

Likewise, maintaining the proper fluid level in the reservoir is critical. A low level can lead to pump cavitation (the formation of vapor bubbles) and aeration, which severely damages components and reduces system performance.

Understanding the Trade-offs and Common Pitfalls

Even with the best intentions, maintenance programs can fall short by focusing on the wrong things or misunderstanding key principles.

The Fallacy of "Run to Failure"

A reactive, "run to failure" approach is immensely expensive. The cost of replacing a failed hydraulic pump is often ten times greater than the cost of the proactive fluid maintenance that would have prevented the failure in the first place. This doesn't even account for the high cost of unplanned downtime.

Ignoring Small Leaks

A small leak is often dismissed as a minor nuisance. In reality, it is a critical warning sign. A leak is not only a point where expensive fluid escapes but also a potential entry point where dirt and moisture can be drawn into the system as it cools.

Improper Fluid Storage and Handling

Contamination often occurs before the fluid even enters the machine. Using dirty containers, open funnels, or leaving fluid drums exposed to the elements are common ways to introduce destructive contaminants from the very start. Always use sealed, clean dispensing equipment.

Creating a Proactive Maintenance Strategy

A reliable hydraulic system is the result of a deliberate, proactive strategy focused on fluid health.

- If your primary focus is maximizing uptime: Implement a scheduled fluid analysis program to predict component wear and fluid degradation before they cause a shutdown.

- If your primary focus is controlling costs: Prioritize clean fluid handling practices and timely filter changes to prevent the premature failure of expensive pumps, motors, and valves.

- If you are just starting a program: Begin with daily visual inspections for leaks, fluid levels, and temperatures, as this is the simplest and most effective first step toward reliability.

By treating the hydraulic fluid as the central component of the system, you fundamentally improve the longevity and performance of your machinery.

Summary Table:

| Maintenance Focus | Key Action | Primary Benefit |

|---|---|---|

| Filtration | Use correct filters & change on schedule | Removes destructive particles, prevents wear |

| Fluid Analysis | Regular oil sampling & testing | Predicts failures, monitors fluid health |

| Temperature Control | Maintain operating temperature range | Prevents fluid degradation & seal damage |

| Leak Prevention | Inspect for and fix leaks promptly | Stops fluid loss and contamination ingress |

Stop Reacting to Hydraulic Failures—Start Preventing Them.

Your hydraulic systems are the lifeblood of your operation. Unplanned downtime and costly component replacements don't have to be your reality. A proactive fluid management strategy is the key to maximizing uptime and controlling maintenance costs.

At KINTEK, we specialize in the precise equipment and consumables needed to keep your lab and industrial machinery running reliably. From filtration systems to fluid analysis supplies, we provide the tools for a data-driven maintenance program.

Ready to transform your hydraulic maintenance? Let our experts help you build a proactive plan. Contact KINTEK today to discuss your specific laboratory equipment needs and ensure your systems operate at peak performance.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Variable Speed Peristaltic Pump

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- How does a hydraulic press ensure quality for PBS/Baobab Powder composite sheets? Achieving Rheological Testing Precision

- What is the role of a laboratory hydraulic press in the solid-phase reduction of red mud? Optimize Sponge Iron Quality

- Purpose of Large-Tonnage Hydraulic Presses in Solid-State Battery Cathodes? Achieve 770 MPa for Maximum Densification

- What role does a laboratory hydraulic press play in ceramic membrane preparation? Master Your Material's Microstructure

- What are the samples for XRF analysis? A Guide to Preparing Solids, Powders, and Liquids

- What is the advantage of a hydraulic press? Harness Immense, Controlled Force for Your Lab

- How does a laboratory hydraulic press facilitate the sample preparation for cellulose citrate? Optimize IR Accuracy