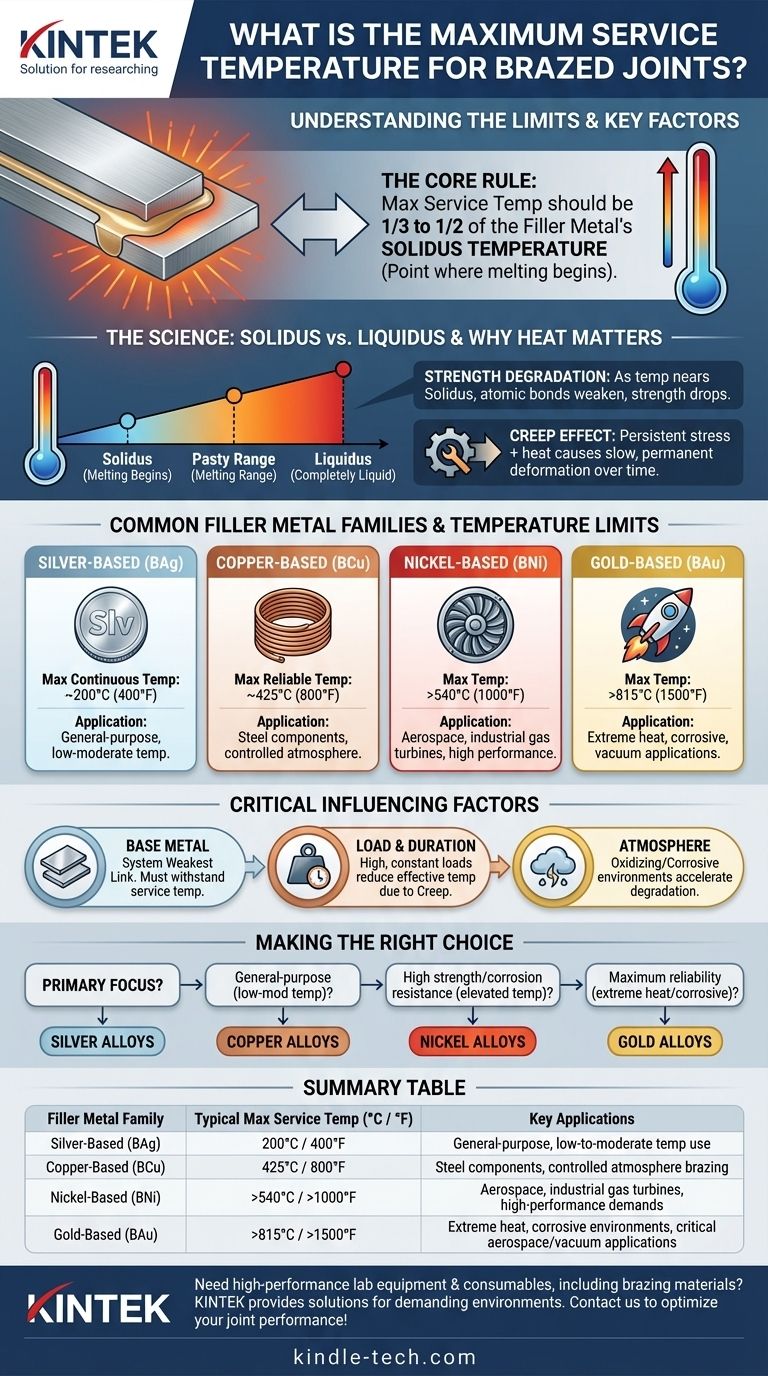

The maximum service temperature of a brazed joint is not a single value but is fundamentally determined by the properties of the filler metal used. As a reliable engineering rule of thumb, the maximum service temperature should not exceed one-third to one-half of the filler metal's solidus temperature (the temperature at which it begins to melt).

The critical takeaway is that a brazed joint's strength degrades significantly as the temperature rises. The safe operating limit is a conservative fraction of the filler metal's melting point, ensuring the joint remains strong enough to handle its designed load without failing over time.

The Core Principle: Solidus Temperature as the Benchmark

To understand why a brazed joint has a temperature limit, you must first understand the behavior of the filler metal that creates the bond.

Defining Solidus and Liquidus

Every brazing alloy has a melting range defined by two key points.

The solidus is the temperature at which the alloy first begins to melt. Below this point, the alloy is completely solid.

The liquidus is the temperature at which the alloy becomes completely liquid. The range between these two points is the alloy's "pasty" or melting range.

Why Strength Degrades with Heat

As the service temperature of a brazed joint approaches the filler metal's solidus, the material's strength drops dramatically. The atomic bonds weaken, making the material softer and more susceptible to deformation under stress.

This weakening is why a significant safety margin is required. Pushing a joint too close to its solidus temperature invites failure, especially under continuous load.

The Impact of Creep

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress. This effect is highly dependent on temperature.

Even at temperatures well below the solidus, a joint under a constant load (like pressure in a pipe or rotational force on a turbine blade) will slowly deform. The higher the temperature and the load, the faster the creep, eventually leading to joint failure.

A Guide to Common Filler Metal Families

The choice of filler metal family is the primary factor in determining a joint's service temperature.

Silver-Based Alloys (BAg)

These are versatile, widely used alloys. They offer excellent flow and wetting on many base metals but have the lowest temperature resistance of the common groups.

Their typical maximum service temperature is around 200°C (400°F) for continuous service.

Copper-Based Alloys (BCu)

Pure copper and copper-phosphorus alloys are often used for brazing steel, stainless steel, and nickel alloys in a controlled atmosphere.

They offer a significant step up in temperature resistance, with reliable service up to 425°C (800°F).

Nickel-Based Alloys (BNi)

Nickel alloys are the standard for high-performance applications requiring excellent strength, corrosion resistance, and oxidation resistance at high temperatures.

These are common in aerospace and industrial gas turbines, with service temperatures often exceeding 540°C (1000°F) and some specialized alloys performing much higher.

Gold-Based Alloys (BAu)

Gold alloys represent a premium choice for the most demanding applications. They provide exceptional ductility and resistance to oxidation and corrosion in extreme environments.

These alloys are used in critical aerospace and vacuum applications where service temperatures can exceed 815°C (1500°F).

Understanding the Trade-offs and Critical Factors

The filler metal is only part of the equation. A truly reliable joint depends on a holistic view of the application.

The Role of the Base Metal

A brazed joint is a system. If the base metals being joined cannot withstand the service temperature, the strength of the braze filler is irrelevant. The maximum operating temperature is always limited by the weakest component in the assembly.

Load and Service Duration

The magnitude and type of stress on the joint are critical. A joint under a high, constant load will have a lower effective service temperature than one experiencing a light, intermittent load due to the effects of creep.

Atmospheric Conditions

The environment the joint operates in plays a major role. A joint exposed to an oxidizing or corrosive atmosphere will degrade faster at high temperatures than one operating in a vacuum or inert environment. The filler metal must be chemically compatible with its service environment.

Making the Right Choice for Your Application

Selecting the correct filler metal requires balancing performance requirements with cost and manufacturability.

- If your primary focus is general-purpose use at low-to-moderate temperatures: Silver alloys provide an excellent, cost-effective solution for a wide range of base metals.

- If your primary focus is joining steel components for service up to 425°C (800°F): Copper and its alloys offer a reliable and economical choice, provided the brazing is done in a protective atmosphere.

- If your primary focus is high strength and corrosion resistance at elevated temperatures: Nickel-based alloys are the industry standard for demanding applications in aerospace and industrial manufacturing.

- If your primary focus is maximum reliability in extreme heat and corrosive environments: Gold and other precious metal alloys provide the ultimate performance, though at a significant cost premium.

By matching the filler metal's capabilities to the specific thermal, mechanical, and environmental demands of your design, you can engineer a brazed joint with confidence and reliability.

Summary Table:

| Filler Metal Family | Typical Maximum Service Temperature (°C / °F) | Key Applications |

|---|---|---|

| Silver-Based (BAg) | 200°C / 400°F | General-purpose, low-to-moderate temperature use |

| Copper-Based (BCu) | 425°C / 800°F | Steel components, controlled atmosphere brazing |

| Nickel-Based (BNi) | >540°C / >1000°F | Aerospace, industrial gas turbines, high-performance demands |

| Gold-Based (BAu) | >815°C / >1500°F | Extreme heat, corrosive environments, critical aerospace/vacuum applications |

Need to ensure your brazed joints can withstand high temperatures? KINTEK specializes in providing high-performance lab equipment and consumables, including brazing materials and solutions tailored for demanding laboratory and industrial environments. Our experts can help you select the right filler metals and processes to achieve reliable, high-temperature joints. Contact us today to discuss your specific application requirements and enhance your joint performance with KINTEK's trusted solutions!

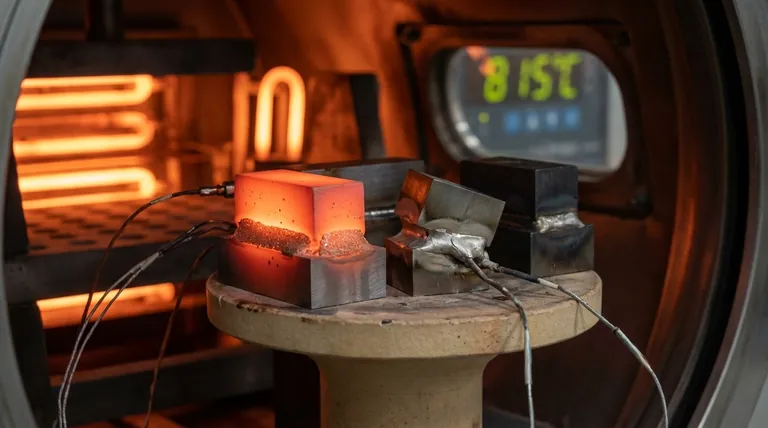

Visual Guide

Related Products

- Copper Foam

- Custom PTFE Teflon Parts Manufacturer for Gaskets and More

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the common applications of copper foam? A Guide to Its High-Performance Uses

- Is copper foam safe? Discover the facts about its antimicrobial and cooling benefits

- What are the characteristics of copper foam? Unlock High-Performance Thermal and Electrical Solutions

- What are the factors that affect heat transfer? Master the Key Variables for Optimal Thermal Performance

- What electrostatic protection measures should be taken when using nickel and copper foam? Essential ESD Safety Protocols