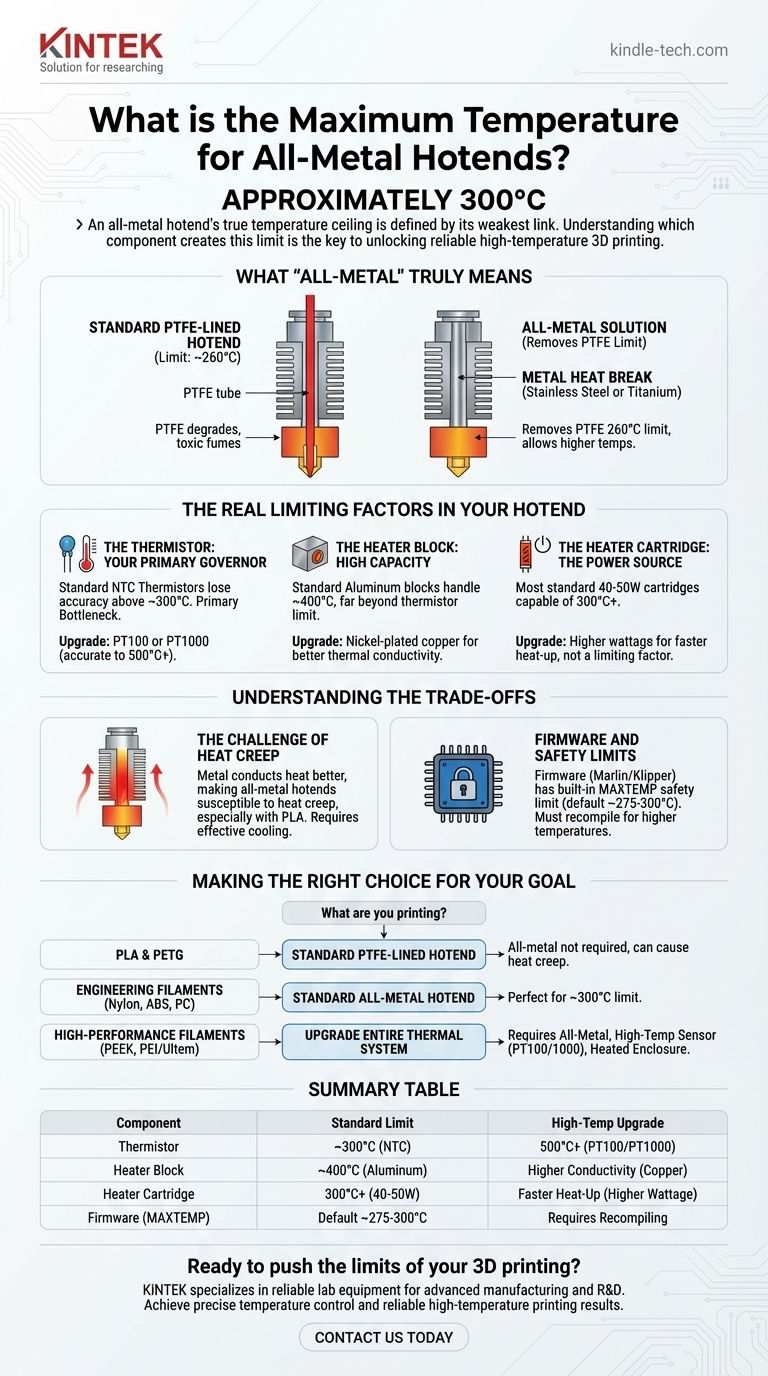

The maximum temperature of an all-metal hotend is not determined by its metal construction but by the limitations of its electronic components. For the vast majority of consumer and prosumer models, this limit is approximately 300°C, governed primarily by the type of thermistor used to measure the temperature. Pushing beyond this requires a systemic upgrade, not just a different hotend.

An all-metal hotend's true temperature ceiling is defined by its weakest link. Understanding which component creates this limit is the key to unlocking reliable high-temperature 3D printing.

What "All-Metal" Truly Means

To understand the temperature limits, we must first define what an "all-metal" hotend is. The distinction lies in a single, critical component.

The Standard, PTFE-Lined Hotend

Most entry-level 3D printers use a hotend where a low-friction PTFE (Teflon) tube runs all the way down to the nozzle. This design is cost-effective and works well for low-temperature materials like PLA.

The critical weakness is the PTFE itself. It begins to degrade and release toxic fumes around 260°C, creating a hard ceiling for safe operation.

The All-Metal Solution

An "all-metal" hotend replaces this internal PTFE liner with a metal tube, typically stainless steel or titanium, known as the heat break.

This single change removes the 260°C limitation of PTFE, allowing the hotend to reach much higher temperatures safely. However, this introduces new limiting factors.

The Real Limiting Factors in Your Hotend

Once the PTFE liner is eliminated, the maximum temperature is passed to other components in the system. The "all-metal" frame can handle extreme heat, but its supporting parts cannot.

The Thermistor: Your Primary Governor

The thermistor is the sensor that reports temperature back to the printer's mainboard. It is almost always the true bottleneck.

Standard NTC thermistors, common in most printers, lose accuracy and risk failure above 285-300°C. For printing above this range, you must upgrade to a different sensor type, such as a PT100 or PT1000, which can accurately measure up to 500°C but may require a dedicated amplifier board.

The Heater Block: High Capacity

The heater block is the piece of metal surrounding the nozzle that houses the heater cartridge and thermistor. Standard blocks are aluminum, which works well up to 400°C, far beyond the thermistor's limit.

Upgraded blocks made of nickel-plated copper offer better thermal conductivity for more stable temperatures but do not inherently increase the maximum temperature limit of the system.

The Heater Cartridge: The Power Source

The heater cartridge provides the energy to melt the filament. Most standard 40W or 50W cartridges are capable of reaching temperatures well over 300°C. While higher wattage cartridges can heat up faster, they are rarely the limiting factor for max temp.

Understanding the Trade-offs

Upgrading to an all-metal hotend is not a simple "more is better" decision. It comes with a significant performance trade-off that requires careful management.

The Challenge of Heat Creep

The primary job of the heat break is to create a sharp thermal boundary, keeping the "hot side" hot and the "cold side" cold. Because metal conducts heat better than PTFE, all-metal hotends are more susceptible to a problem called heat creep.

Heat creep occurs when heat travels too far up the filament path, softening it before it reaches the melt zone. This leads to frustrating clogs and jams, especially with low-temperature materials like PLA. Effective part cooling is far more critical with an all-metal hotend.

Firmware and Safety Limits

Your printer's firmware (like Marlin or Klipper) has a built-in safety limit, often labeled MAXTEMP. This is a hard-coded value that will shut the printer down if the thermistor reports a temperature exceeding it.

Simply changing the hotend does not change this firmware limit. You must recompile and flash new firmware to enable temperatures beyond the default setting, but only after you have confirmed all hardware components can support it.

Making the Right Choice for Your Goal

Selecting a hotend depends entirely on the materials you intend to print. Use this as your guide.

- If your primary focus is PLA and PETG: An all-metal hotend is not required and can introduce heat creep issues if cooling is not optimized. A standard PTFE-lined hotend is often more reliable.

- If your primary focus is Engineering Filaments (Nylon, ABS, PC): A standard all-metal hotend is the perfect choice, as its typical 300°C limit comfortably accommodates the printing temperatures for these materials.

- If your primary focus is High-Performance Filaments (PEEK, PEI/Ultem): You must upgrade the entire thermal system. This includes an all-metal hotend, a high-temperature sensor (PT100/1000), and a heated enclosure to control the ambient air temperature.

Ultimately, understanding that your hotend is a system of interconnected components empowers you to make an informed decision and achieve your specific printing goals.

Summary Table:

| Component | Standard Limit | High-Temp Upgrade |

|---|---|---|

| Thermistor | ~300°C (NTC) | 500°C+ (PT100/PT1000) |

| Heater Block | ~400°C (Aluminum) | Higher Conductivity (Copper) |

| Heater Cartridge | 300°C+ (40-50W) | Faster Heat-Up (Higher Wattage) |

| Firmware (MAXTEMP) | Default ~275-300°C | Requires Recompiling |

Ready to push the limits of your 3D printing?

Whether you're optimizing for engineering filaments like Nylon and ABS or exploring high-performance materials like PEEK and PEI/Ultem, the right lab equipment is crucial for success. KINTEK specializes in providing reliable lab equipment and consumables to support your advanced manufacturing and R&D needs.

Contact us today to discuss how our solutions can help you achieve precise temperature control and reliable high-temperature printing results.

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Electrode Fixture for Electrochemical Experiments

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the general procedure and what precautions should be taken during the polishing process? Achieve a Flawless Electrode Finish

- How does a laboratory hydraulic press contribute to MIC testing? Ensure Precision in Stainless Steel Specimens

- What is a hot mounting press machine? Precision Control for Metallurgy & Electronics Assembly

- What is the purpose of using epoxy resin and laboratory mounting equipment? Precision in U71Mn Weld Area Analysis

- How should a sample be installed onto the sample holder? Ensure Mechanical Stability & Electrical Integrity