At its core, Physical Vapor Deposition (PVD) is a method for creating high-performance thin films. The mechanism involves placing a solid source material (a "target") in a high vacuum, applying energy to vaporize its surface atoms, and allowing this vapor to travel and condense onto a component (the "substrate"), building a new surface layer atom by atom.

The central principle of PVD is the physical transfer of material, not a chemical reaction. Think of it like water vapor from a boiling kettle condensing on a cold mirror—the process simply moves the material from one place to another in a different state, all within a controlled vacuum environment.

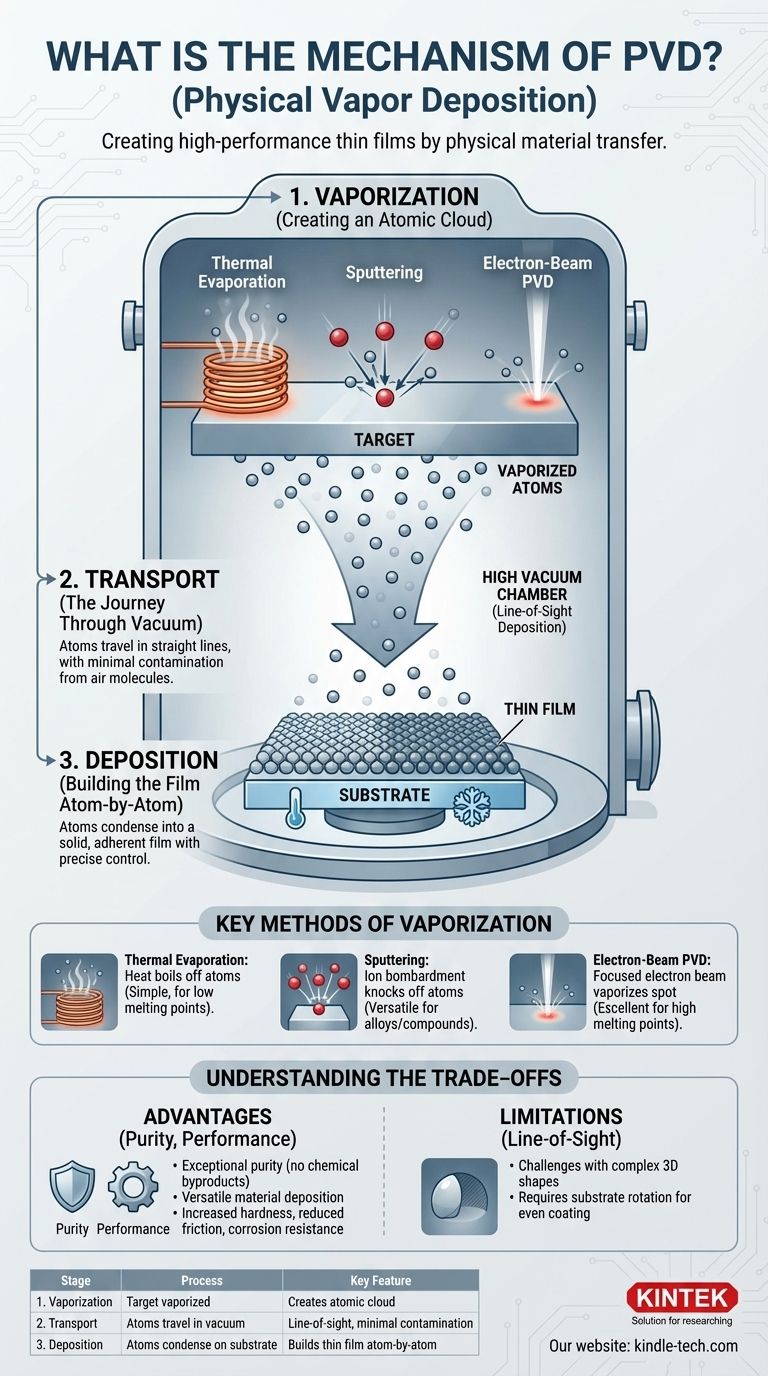

The Three Fundamental Stages of PVD

The entire PVD process, regardless of the specific technique used, can be broken down into three distinct stages. Understanding this sequence is key to understanding how PVD works.

Stage 1: Vaporization (Creating an Atomic Cloud)

The process begins with a solid block or piece of the desired coating material, known as the target. This target is subjected to a high-energy source inside a vacuum chamber.

This energy effectively "boils" or ejects atoms from the surface of the target, converting the solid material directly into a gaseous vapor. The specific method of vaporization is what differentiates the various types of PVD.

Stage 2: Transport (The Journey Through Vacuum)

Once atoms are freed from the target, they travel through the chamber. This journey takes place in a high vacuum (very low pressure), which is critical for two reasons.

First, the vacuum ensures there are minimal air or gas molecules for the vaporized atoms to collide with, preventing contamination. Second, it allows the atoms to travel in a straight line from the source to the substrate, a characteristic known as line-of-sight deposition.

Stage 3: Deposition (Building the Film Atom-by-Atom)

The vaporized atoms eventually reach the substrate, which is often cooler. Upon contact, they condense back into a solid state, forming a thin, highly adherent film.

This layer builds up one atom at a time, allowing for exceptional control over thickness, structure, and purity. Because no chemical reactions occur, the deposited film is composed of the same material as the original target.

Key Methods of Vaporization in PVD

While the transport and deposition stages are similar, the vaporization method defines the specific PVD technique and its ideal applications.

Thermal Evaporation

This is the simplest method. The target material is heated by electrical resistance until its atoms "boil off" and create a vapor, much like boiling water creates steam. It is suitable for materials with relatively low melting points.

Sputtering

In this process, the target is bombarded with high-energy ions (typically from a gas like Argon). These ions act like microscopic billiard balls, knocking atoms off the target material. Sputtering is highly versatile and can be used for a wide range of materials, including alloys and compounds.

Electron-Beam PVD (E-Beam PVD)

Here, a high-energy beam of electrons is magnetically guided to strike the target material. The intense, focused energy causes a localized spot on the target to vaporize. This technique is excellent for materials with very high melting points that are difficult to evaporate thermally.

Understanding the Trade-offs

PVD is a powerful technology, but it is essential to understand its advantages and limitations to apply it correctly.

Advantage: Purity and Versatility

The vacuum environment ensures an exceptionally pure coating, free from the byproducts of chemical reactions. PVD can deposit nearly any metal, alloy, or ceramic compound, making it extremely versatile.

Advantage: Performance Enhancement

PVD coatings are widely used to improve the surface properties of a component. Common benefits include significantly increased hardness, reduced friction, and enhanced resistance to oxidation and corrosion.

Limitation: Line-of-Sight Deposition

Because atoms travel in a straight line, surfaces that are not in the direct line-of-sight of the source will not get coated. This makes it challenging to evenly coat complex 3D shapes. Fixtures that rotate the substrate during deposition are often required to mitigate this effect.

Making the Right Choice for Your Goal

To decide if PVD is the right approach, consider your primary objective for the coating.

- If your primary focus is high-purity, ultra-thin films: PVD is an ideal choice due to the clean vacuum environment and atomic-level control over thickness.

- If your primary focus is coating complex 3D shapes evenly: Be aware of PVD's line-of-sight limitation and ensure your process includes substrate rotation, or consider an alternative like Chemical Vapor Deposition (CVD).

- If your primary focus is enhancing hardness and wear resistance on tools: PVD is a leading industry standard for applying hard coatings like Titanium Nitride (TiN) and is an excellent selection.

Ultimately, PVD provides a precise and powerful mechanism for engineering the surface of a material at the atomic level.

Summary Table:

| Stage | Process | Key Feature |

|---|---|---|

| 1. Vaporization | Target material is vaporized | Creates atomic cloud of coating material |

| 2. Transport | Atoms travel through vacuum | Line-of-sight deposition, minimal contamination |

| 3. Deposition | Atoms condense on substrate | Builds thin film atom-by-atom |

Ready to enhance your materials with precision PVD coatings? KINTEK specializes in advanced lab equipment and consumables for thin film deposition. Our expertise in PVD technology can help you achieve superior surface properties like increased hardness, reduced friction, and enhanced corrosion resistance. Contact our experts today to discuss how our solutions can meet your specific laboratory needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process