There is no single minimum temperature for sintering. This is because sintering is not a fixed physical event like the freezing point of water, but a process that is entirely dependent on the material being heated. Sintering is driven by atomic diffusion, which occurs at vastly different temperatures for plastics, metals, and ceramics.

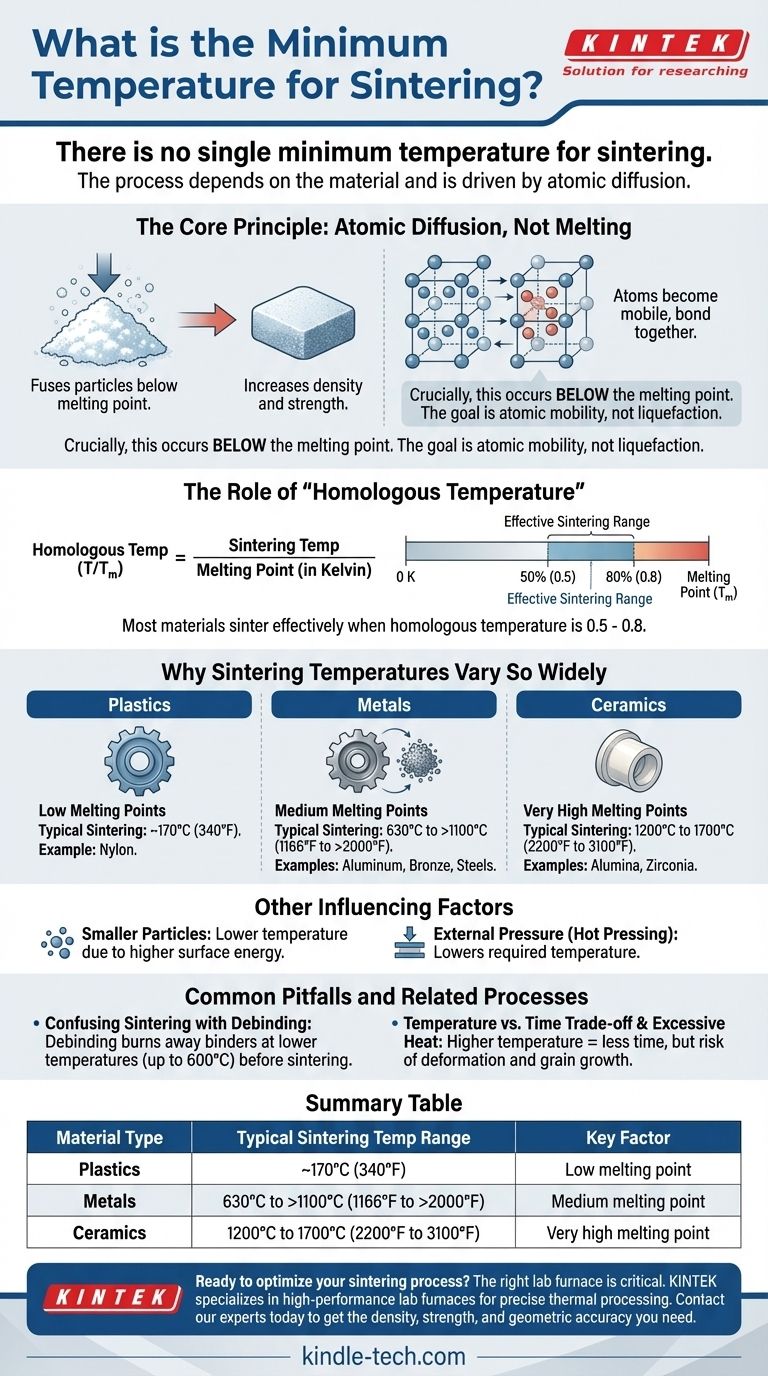

The critical concept to understand is that sintering temperature is relative to a material's melting point. As a rule of thumb, effective sintering occurs at a temperature between 50% and 80% of the material's absolute melting temperature, allowing atoms to fuse particles together without the material losing its shape.

The Core Principle: Atomic Diffusion, Not Melting

What Sintering Actually Is

Sintering is a thermal process that fuses particles of material together, increasing density and strength.

Imagine pressing a handful of loose snow together to form a solid snowball. Heat and pressure in sintering achieve a similar effect at the atomic level, bonding individual particles into a solid mass.

Crucially, this happens below the material's melting point. The goal is to make the atoms mobile enough to bond, not to turn the material into a liquid.

The Role of "Homologous Temperature"

The key to understanding sintering temperatures is the concept of homologous temperature.

This is the ratio of the sintering temperature to the material's melting point, both measured on an absolute scale (Kelvin).

Most materials begin to sinter effectively when they reach a homologous temperature between 0.5 and 0.8 (or 50% to 80%). This range provides enough thermal energy for atoms to diffuse across particle boundaries and fill in the gaps between them.

Why Sintering Temperatures Vary So Widely

Since the sintering temperature is a percentage of the melting point, the vast differences in melting points between materials lead to an equally wide range of sintering temperatures.

Material Type is the Primary Factor

- Plastics: With low melting points, some plastics like nylon can be sintered at temperatures as low as 170°C (340°F).

- Metals: Common metals require significantly more heat. The 630°C mentioned in one analysis is typical for aluminum or bronze alloys, while steels require temperatures well over 1100°C (2000°F).

- Ceramics: With extremely high melting points, ceramics like alumina or zirconia require very high sintering temperatures, often in the range of 1200°C to 1700°C (2200°F to 3100°F).

Other Influencing Factors

While material type is dominant, other factors can adjust the required temperature.

Smaller particles have higher surface energy and will sinter at a slightly lower temperature than larger particles. Applying external pressure during heating (a process called hot pressing) can also lower the necessary temperature.

Common Pitfalls and Related Processes

Confusing Sintering with Debinding

Debinding is a separate, preliminary step used in some forms of metal and ceramic manufacturing.

This process uses low heat (typically up to 600°C) to burn away a polymer "binder" that holds the particles together in their green state. The actual sintering only begins after the debinding phase is complete and the temperature is raised much higher.

The Temperature vs. Time Trade-off

Sintering is a function of both temperature and time.

You can often achieve a similar density by sintering at a slightly lower temperature for a longer duration. Conversely, a higher temperature can achieve the same result in less time. This trade-off is critical for process optimization.

The Risk of Excessive Heat

Using a temperature that is too high or too close to the melting point can be detrimental. It can cause the part to slump or deform, losing its intended shape. It can also cause excessive grain growth within the material's microstructure, which often leads to poor mechanical properties like brittleness.

Making the Right Choice for Your Goal

To determine the correct temperature, you must first define your material and your objective.

- If your primary focus is working with a known material: Start with the established industry standard for that material, which will fall within the 50-80% of its absolute melting point range.

- If your primary focus is optimizing a process: Carefully explore the trade-off between temperature and time. A lower temperature for a longer duration might prevent unwanted grain growth and improve the final part's properties.

- If your primary focus is troubleshooting part deformation: Your temperature is almost certainly too high. Reduce it to ensure you are well below the material's melting point to maintain geometric accuracy.

Ultimately, understanding that sintering is a process of atomic motion empowers you to control the outcome by intelligently balancing temperature, time, and material properties.

Summary Table:

| Material Type | Typical Sintering Temperature Range | Key Factor |

|---|---|---|

| Plastics | ~170°C (340°F) | Low melting point |

| Metals | 630°C to >1100°C (1166°F to >2000°F) | Medium melting point |

| Ceramics | 1200°C to 1700°C (2200°F to 3100°F) | Very high melting point |

Ready to optimize your sintering process? The right lab furnace is critical for achieving the perfect balance of temperature and time for your specific material. KINTEK specializes in high-performance lab furnaces and consumables designed for precise thermal processing of plastics, metals, and ceramics. Contact our experts today to discuss your application and ensure you get the density, strength, and geometric accuracy you need.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is a physical vapor deposition apparatus? A Guide to Thin-Film Coating Technology

- What is a scientific mixer called? Choosing the Right Mixer for Your Lab

- What are the advantages of the sintering process? Achieve Cost-Effective, Complex Parts

- What is ferronickel used for? The Essential Alloy for Stainless Steel Production

- How does a constant temperature heating and stirring device ensure the quality of silver (Ag) nanosphere seed synthesis?

- Can people tell the difference between real and fake diamonds? The Truth About Lab-Grown vs. Natural

- What are the benefits of staying updated with the latest ULT freezer technologies? Save Costs & Boost Sustainability

- What is the purpose of using 5000 mesh grinding consumables for the fine polishing of alloy samples? Achieve Precision