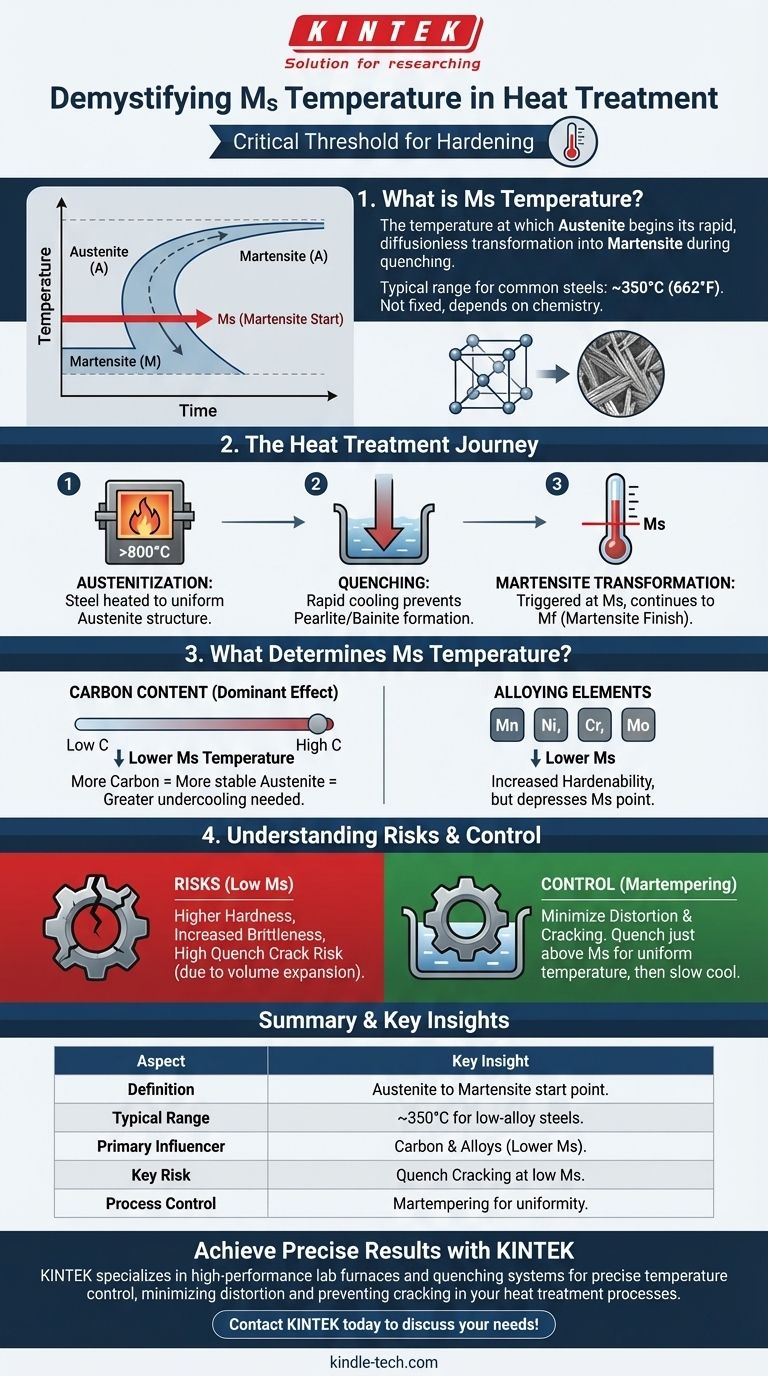

In heat treatment, Ms temperature is the critical threshold where the hardening transformation of steel begins. It stands for Martensite start, representing the precise temperature at which austenite, the high-temperature phase of steel, starts to convert into martensite, a very hard and brittle structure, during rapid cooling (quenching). For common low-carbon, low-alloy steels, this transformation typically begins around 350°C (662°F).

The Ms temperature is not a fixed constant but a variable property of the steel itself, primarily determined by its chemical composition. Understanding this value is essential for predicting a steel's response to quenching, allowing you to achieve the desired hardness while controlling risks like cracking and distortion.

The Role of Ms in the Quenching Process

To control the final properties of a steel component, you must first understand the journey it takes during heat treatment. The Ms temperature is arguably the most important landmark on that journey.

From Austenite to Martensite

Heat treatment for hardening begins by heating steel into the austenitic range (typically above 800°C or 1475°F). At this temperature, the steel has a uniform crystalline structure called austenite, which can dissolve a significant amount of carbon.

The goal of quenching is to cool the steel so rapidly that the carbon atoms do not have time to diffuse out and form softer structures like pearlite or bainite.

The Transformation Trigger

As the steel is quenched, its temperature plummets past the points where other transformations would normally occur. Once it cools to the Ms temperature, the transformation to martensite is triggered.

This transformation is diffusionless, meaning it happens almost instantly through a shear-like mechanism within the crystal lattice, trapping carbon atoms in place. This trapped carbon is what gives martensite its extreme hardness and strength.

Beyond the Start Point (Mf)

The formation of martensite does not happen all at once. It begins at the Ms temperature and continues as the component cools further.

The transformation is essentially complete when the steel reaches the Mf (martensite finish) temperature. The temperature range between Ms and Mf is critical for managing internal stresses.

What Determines the Ms Temperature?

The Ms temperature is a function of the steel's chemistry. Different elements dissolved in the austenite will raise or lower the temperature at which the martensitic transformation can begin.

The Dominant Effect of Carbon

Carbon is the single most influential element affecting the Ms temperature. As the carbon content in the steel increases, the Ms temperature significantly decreases.

This is a fundamental principle: more carbon makes the austenite more stable, requiring greater undercooling to force the transformation to martensite.

The Influence of Other Alloying Elements

Nearly all other common alloying elements—such as manganese, nickel, chromium, and molybdenum—also lower the Ms temperature.

These elements are added to increase hardenability (the ability to form martensite deeper into a part), but a direct consequence is the depression of the Ms point. Metallurgists use established empirical formulas to predict the Ms temperature based on a steel's complete chemical composition.

Understanding the Trade-offs and Risks

Knowing the Ms temperature is not just an academic exercise; it has direct and critical consequences for the success of your heat treatment process.

Predicting Hardness and Brittleness

A lower Ms temperature, typically resulting from higher carbon and alloy content, allows more carbon to be trapped in the final structure. This directly correlates to a higher potential as-quenched hardness and strength, but also to increased brittleness.

The Risk of Quench Cracks

The transformation from austenite to martensite involves a significant volume expansion (up to 4%). When this transformation occurs at a lower temperature (a low Ms), the steel is less ductile and less able to accommodate this internal stress.

This is the primary cause of quench cracking. A low Ms temperature dramatically increases this risk, as the material is transforming while it is already cool and brittle.

Controlling Distortion

Knowing the Ms allows you to design a smarter quenching cycle. Processes like martempering involve quenching the part in a medium (like molten salt) held at a temperature just above Ms.

The part is held there long enough for its entire cross-section to reach a uniform temperature before being cooled slowly through the Ms-Mf range. This ensures the martensitic transformation occurs uniformly, drastically reducing thermal stress, distortion, and the risk of cracking.

Making the Right Choice for Your Goal

The Ms temperature is a key piece of data for anyone specifying or performing heat treatment. Your approach should be dictated by your end goal.

- If your primary focus is maximizing hardness and wear resistance: Select a steel with higher carbon and alloy content, but be aware this lowers the Ms temperature and requires a carefully controlled quenching process to mitigate the high risk of cracking.

- If your primary focus is minimizing distortion and cracking in complex parts: Prioritize steels with a higher Ms temperature or insist on specialized quenching processes like martempering that manage the cooling rate around this critical point.

- If you are selecting a new steel for a hardened component: Always use its chemical composition to calculate or look up the Ms temperature. This allows you to anticipate its response to quenching and avoid costly failures.

Ultimately, understanding the Ms temperature transforms heat treatment from a reactive process into a predictive science, giving you direct control over the final outcome.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Definition | Ms is the temperature at which austenite starts transforming into martensite during quenching. |

| Typical Range | Around 350°C (662°F) for common low-carbon, low-alloy steels. |

| Primary Influencer | Carbon content: higher carbon significantly lowers the Ms temperature. |

| Key Risk | A low Ms temperature increases the risk of quench cracking due to higher stress. |

| Process Control | Enables specialized techniques like martempering to minimize distortion. |

Achieve precise and predictable results in your heat treatment processes.

Understanding the Ms temperature is critical, but applying that knowledge requires the right equipment. KINTEK specializes in high-performance lab furnaces and quenching systems that deliver the precise temperature control and rapid cooling rates essential for successful martensitic transformations.

Whether you are developing new alloys or hardening complex components, our solutions help you minimize distortion and prevent cracking. Let our experts help you select the perfect equipment for your specific steel and application.

Contact KINTEL today to discuss your laboratory's heat treatment needs and ensure your next project is a success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- What materials are used in a vacuum furnace? Selecting the Right Hot Zone for Your Process

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability