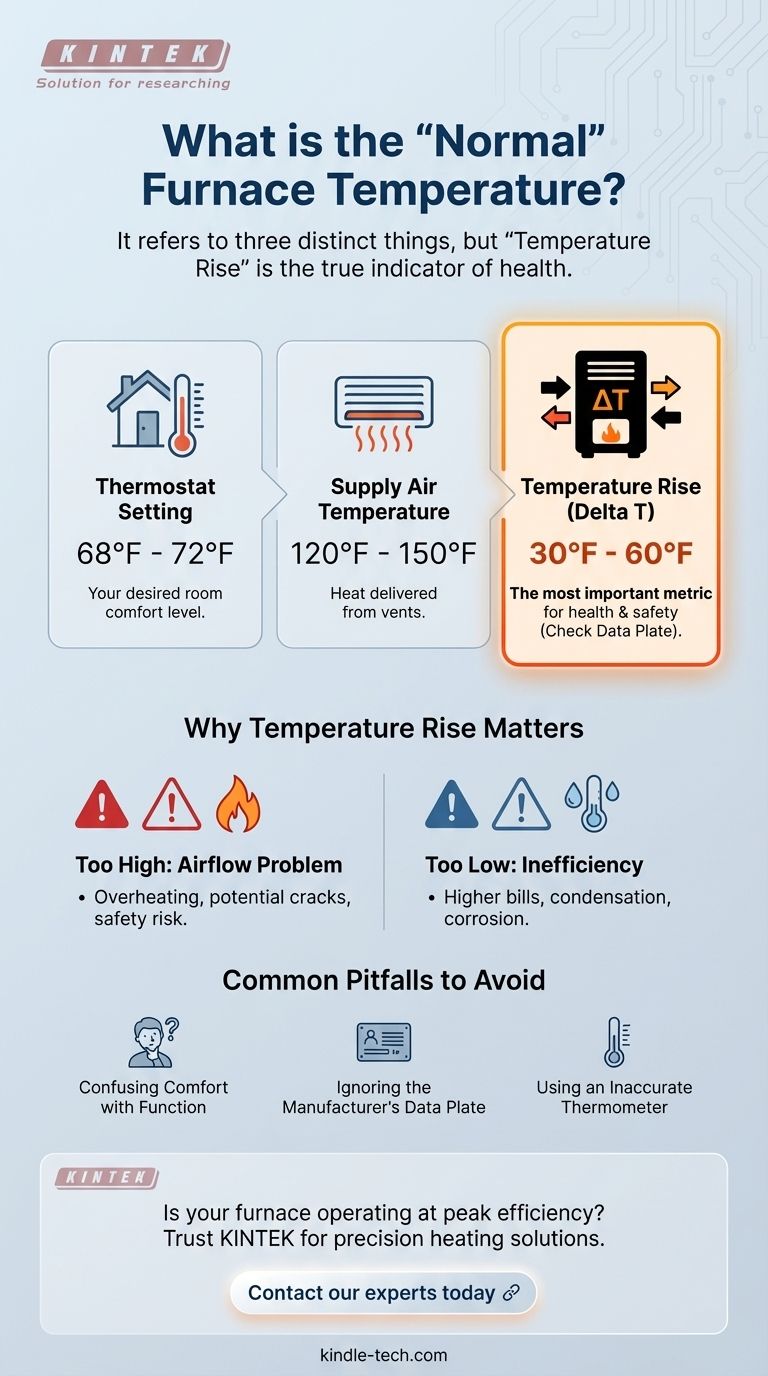

In a home heating system, the term "normal furnace temperature" can refer to three distinct things. While your thermostat is typically set between 68-72°F for comfort, the air coming out of your vents should be significantly hotter, usually between 120°F and 150°F. The most important technical measure, however, is the "temperature rise"—the difference between the air entering and exiting the furnace—which is the true indicator of its health.

The concept of a single "normal temperature" is a misconception. The key to understanding your furnace's health is not a specific number, but the specified temperature rise listed by the manufacturer, which ensures the unit is heating air efficiently and safely.

The Three "Normal" Temperatures of a Furnace

To properly assess your furnace, it's crucial to understand which temperature you are measuring and what it signifies. Each tells a different part of the story about your home's heating system.

Thermostat Setting (Your Comfort Zone)

This is the temperature you set for your living space. Most homeowners find a range of 68°F to 72°F to be a comfortable and energy-efficient baseline during the winter.

This number is purely a user preference and a command to the system. It tells the furnace when to turn on and off, but it does not reflect the internal operating temperature or the health of the unit itself.

Supply Air Temperature (What Comes Out of the Vents)

This is the temperature of the hot air being delivered through your supply vents. For most gas furnaces, this air should be in the range of 120°F to 150°F.

If the air feels lukewarm or cool, it can be a sign of a problem. This temperature provides a quick, tangible sense of whether the furnace is generating a substantial amount of heat.

Temperature Rise (The Key Performance Metric)

This is the most critical measurement for an HVAC professional and the true indicator of furnace health. Temperature rise (also called Delta T) is the difference between the temperature of the air going into the furnace (return air) and the temperature of the air coming out (supply air).

Every furnace has a data plate on the unit that specifies the acceptable temperature rise range, typically between 30°F and 60°F. This is the definitive "normal" operating parameter for your specific model.

Why Your Furnace's Temperature Rise Matters

Operating outside the manufacturer's specified temperature rise range is not just inefficient; it can be dangerous and cause premature failure of the equipment.

A Rise That's Too High

A temperature rise above the specified range is a critical warning sign. It almost always indicates an airflow problem, such as a severely clogged air filter, blocked vents, or an undersized duct system.

This restricted airflow prevents the furnace from shedding heat fast enough. This can cause the heat exchanger to overheat, potentially leading to cracks and creating a serious safety hazard.

A Rise That's Too Low

A temperature rise below the specified range means the furnace isn't transferring enough heat to the air. This can be caused by low gas pressure, dirty burners, or an oversized system.

This condition leads to inefficiency, higher utility bills, and can cause condensation to form inside the furnace, which may lead to corrosion and a shortened lifespan for the unit.

Common Pitfalls to Avoid

Understanding these distinctions helps you avoid common and costly misinterpretations about your furnace's performance.

Confusing Comfort with Function

Don't assume that because your house feels cold, the furnace itself is failing. The issue could be poor insulation, air leaks, or simply an undersized unit for the space.

Ignoring the Manufacturer's Data Plate

The data plate on your furnace is the ultimate source of truth. It contains the model-specific temperature rise range that a technician will use to diagnose the health of your system.

Using an Inaccurate Thermometer

While you can get a rough idea with a meat or infrared thermometer at a vent, these readings aren't precise. For an accurate diagnosis, a technician uses calibrated digital thermometers to measure the air temperature directly before and after the furnace unit.

How to Apply This to Your Project

Use this understanding to determine the right course of action for your specific situation.

- If your primary focus is energy savings: Concentrate on your thermostat setting. A range of 68-70°F is a good starting point, and using sweaters or blankets can help you adjust to a lower, more economical temperature.

- If you suspect a performance issue: A simple check is to feel the air from a supply vent. If it feels lukewarm instead of distinctly hot, it confirms that further investigation is needed.

- If you want a definitive health check: Locate the data plate on your furnace to find the specified "temperature rise" and have an HVAC professional perform a measurement to ensure your system is operating safely and effectively within that range.

Knowing what these different temperatures mean empowers you to move from simply feeling cold to identifying the true source of a potential problem.

Summary Table:

| Temperature Type | Typical Range | What It Means |

|---|---|---|

| Thermostat Setting | 68°F - 72°F | Your desired room temperature (comfort level). |

| Supply Air Temperature | 120°F - 150°F | The heat of the air coming out of your vents. |

| Temperature Rise (Delta T) | 30°F - 60°F | The most important metric for furnace health and safety. |

Is your furnace operating at peak efficiency and safety?

Understanding your furnace's temperature is the first step. For precise temperature control and reliable performance in any application, trust the equipment experts at KINTEK. We specialize in high-quality heating solutions for laboratories and industrial settings, ensuring accuracy, safety, and durability.

Let KINTEK be your partner in precision heating. Contact our experts today to discuss your specific needs and find the perfect solution for your project.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What PPE should you ensure is available when operating a furnace? A Complete Guide to Staying Safe

- Why hydrogen is used in sintering process? Achieve Superior Purity and Strength in Metal Parts

- What specific environmental conditions does a vacuum sintering furnace provide for transparent Yttrium Oxide ceramics?

- What is plasma pyrolysis waste treatment and disposal? Convert Waste into Clean Energy & Inert Materials

- What is the working mechanism of an anoxic pyrolysis reactor? Key to Green Hydrogen Production

- What are the outcomes of heat treatment? Tailor Material Properties for Superior Performance

- What is the significance of thermal gradient simulation and thermal cycling furnaces? Ensure Reactor Component Safety

- What are the advanced heat treatment techniques? Achieve Precision, Durability, and Superior Performance