The primary objective of a muffle furnace is to heat a material to a very high temperature while ensuring it remains completely isolated from the heating source and any contaminants it might produce. This is achieved by placing the sample inside a "muffle"—a self-contained, heat-resistant inner chamber—which is then heated externally. This design guarantees that byproducts like combustion gases, soot, or ash cannot come into contact with the material being treated.

The core value of a muffle furnace is its ability to create a pure, uncontaminated, high-temperature environment. This separation is critical for processes where the chemical and physical integrity of the sample must be preserved without interference from the heating process itself.

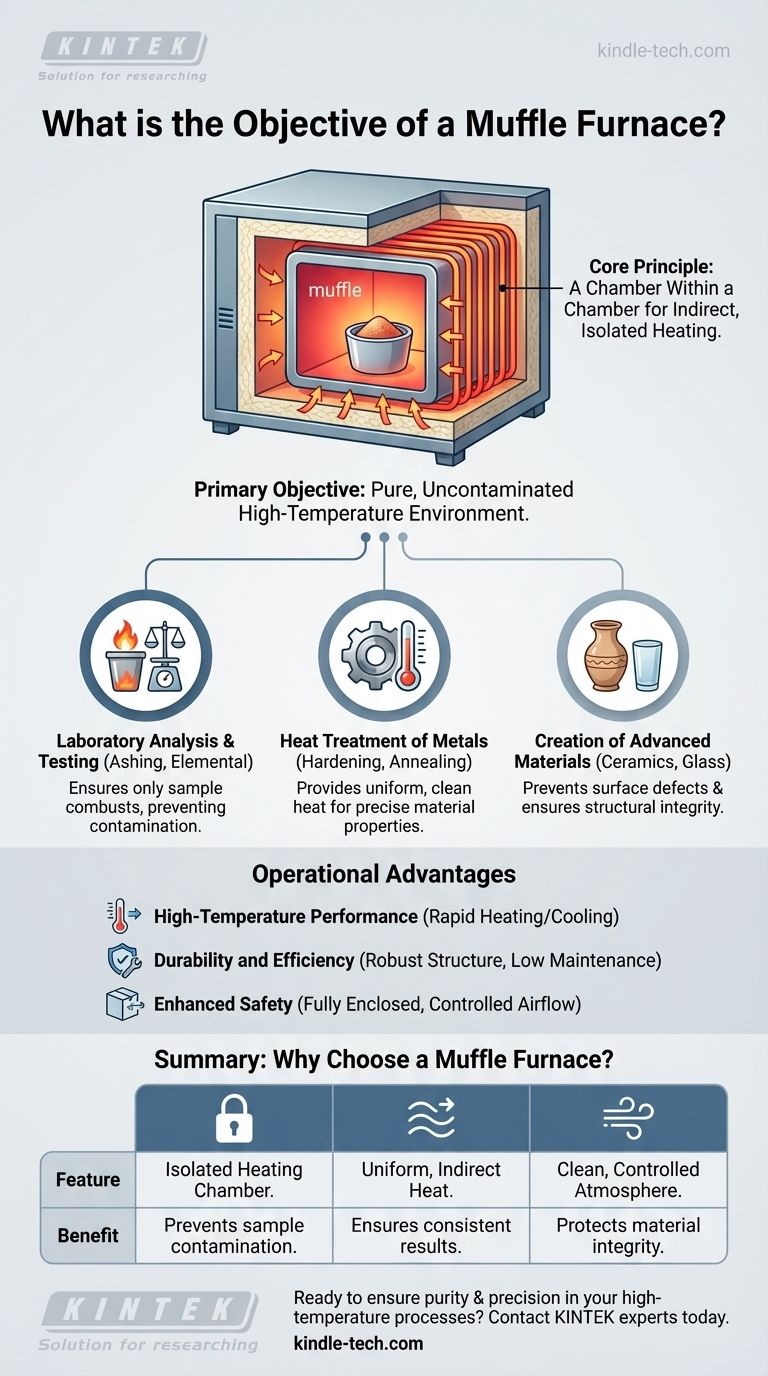

The Core Principle: A Chamber Within a Chamber

The defining characteristic of a muffle furnace is its indirect heating method. Understanding this simple concept clarifies its purpose and applications across various fields.

What is the "Muffle"?

The muffle is the heat-resistant inner container that holds the material to be heated. This chamber acts as a protective barrier, shielding the contents from direct exposure to the heating elements or flames.

Historically, this was designed to protect materials from the fuel, ash, and fumes of combustion.

How Modern Furnaces Work

In modern electric muffle furnaces, high-temperature heating coils are positioned outside the muffle chamber. These coils apply heat to the chamber through radiation and convection.

The insulated material of the furnace acts as the muffle, heating the internal space uniformly while preventing heat from escaping, leading to high energy efficiency.

Key Applications Driven by Purity and Temperature

The need for a clean, high-heat environment makes muffle furnaces indispensable for specific technical applications where contamination would compromise the results or the final product.

Laboratory Analysis and Testing

Muffle furnaces are used for processes like ashing, where a sample is burned to determine its inorganic content. The isolated chamber ensures that only the sample itself is combusted, without adding contaminants from a fuel source.

This is also critical for detecting elements in materials like coal.

Heat Treatment of Metals

Processes such as hardening, annealing, and tempering require precise temperature control in a clean atmosphere. A muffle furnace provides the uniform, indirect heat needed to alter the metal's properties without causing surface oxidation or contamination.

Creation of Advanced Materials

Manufacturing processes for ceramics, fused glass, and enamel coatings are highly sensitive to atmospheric impurities. A muffle furnace's isolated environment prevents unwanted chemical reactions, ensuring the structural integrity and aesthetic quality of the final product.

The Operational Advantages of the Muffle Design

The design philosophy of a muffle furnace not only ensures purity but also delivers several practical benefits that make it a standard tool in professional settings.

High-Temperature Performance

These furnaces are engineered for rapid high-temperature heating, recovery, and cooling within a self-contained cabinet.

Durability and Efficiency

Their structure is typically simple and robust, leading to a long service life with low maintenance costs. Modern designs with integral door frames and step-type assembling ensure the hearth does not collapse and that heat energy is not easily dissipated.

Enhanced Safety

Because the heating process is fully enclosed, muffle furnaces are safe to operate. Many models use mechanical convection to direct airflow out of an exhaust, often eliminating the need for a separate fume hood.

Making the Right Choice for Your Application

Selecting the right heating equipment depends entirely on whether your process can tolerate exposure to the byproducts of direct heating.

- If your primary focus is analytical purity (e.g., ashing, elemental analysis): A muffle furnace is non-negotiable, as it is the only way to prevent sample contamination.

- If your primary focus is creating sensitive materials (e.g., ceramics, glass, enamel): The isolated atmosphere is essential for preventing surface defects and ensuring product integrity.

- If your primary focus is metallurgical heat treatment (e.g., annealing, tempering): The furnace provides the precise, uniform, and clean heat required to achieve specific material properties reliably.

Ultimately, a muffle furnace is the definitive solution whenever a high-temperature process demands absolute separation between the material and the heat source.

Summary Table:

| Key Feature | Primary Benefit | Ideal Application |

|---|---|---|

| Isolated Heating Chamber | Prevents sample contamination | Analytical testing (e.g., ashing) |

| Uniform, Indirect Heat | Ensures consistent results | Metallurgical heat treatment |

| Clean, Controlled Atmosphere | Protects material integrity | Creating ceramics, glass, and enamels |

| High-Temperature Performance | Rapid heating and cooling cycles | Various laboratory and industrial processes |

Ready to ensure purity and precision in your high-temperature processes?

KINTEK specializes in high-performance laboratory equipment, including durable and efficient muffle furnaces designed for applications where contamination-free results are critical. Whether your lab focuses on material testing, metal heat treatment, or advanced material creation, our solutions deliver the reliable, clean environment you need.

Contact our experts today to find the perfect muffle furnace for your specific laboratory requirements and enhance your process integrity.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the tolerance of a muffle furnace? A Guide to Temperature Accuracy & Uniformity

- What is ashing in a muffle furnace? Isolate Inorganic Content with Precision

- What is the temperature of a muffle furnace ashing? Find Your Precise Ashing Temperature

- What is the ashing method of muffle furnace? A Guide to Accurate Sample Analysis

- What is the capacity of a muffle furnace? Find the Right Size for Your Lab Needs