At its core, Vacuum Arc Remelting (VAR) is a high-purity secondary melting process used to refine metals and special alloys. It operates by striking a powerful DC electric arc to melt a pre-made metal rod (the electrode) inside a vacuum chamber. The molten metal drips down and re-solidifies in a water-cooled copper mold, producing a new, highly purified ingot with a superior internal structure.

The true purpose of VAR is not to make metal from raw ore, but to take an existing alloy and elevate its quality. By remelting it under vacuum, the process removes dissolved gases and volatile impurities, resulting in an ultra-clean material with exceptional mechanical properties required for the most demanding applications.

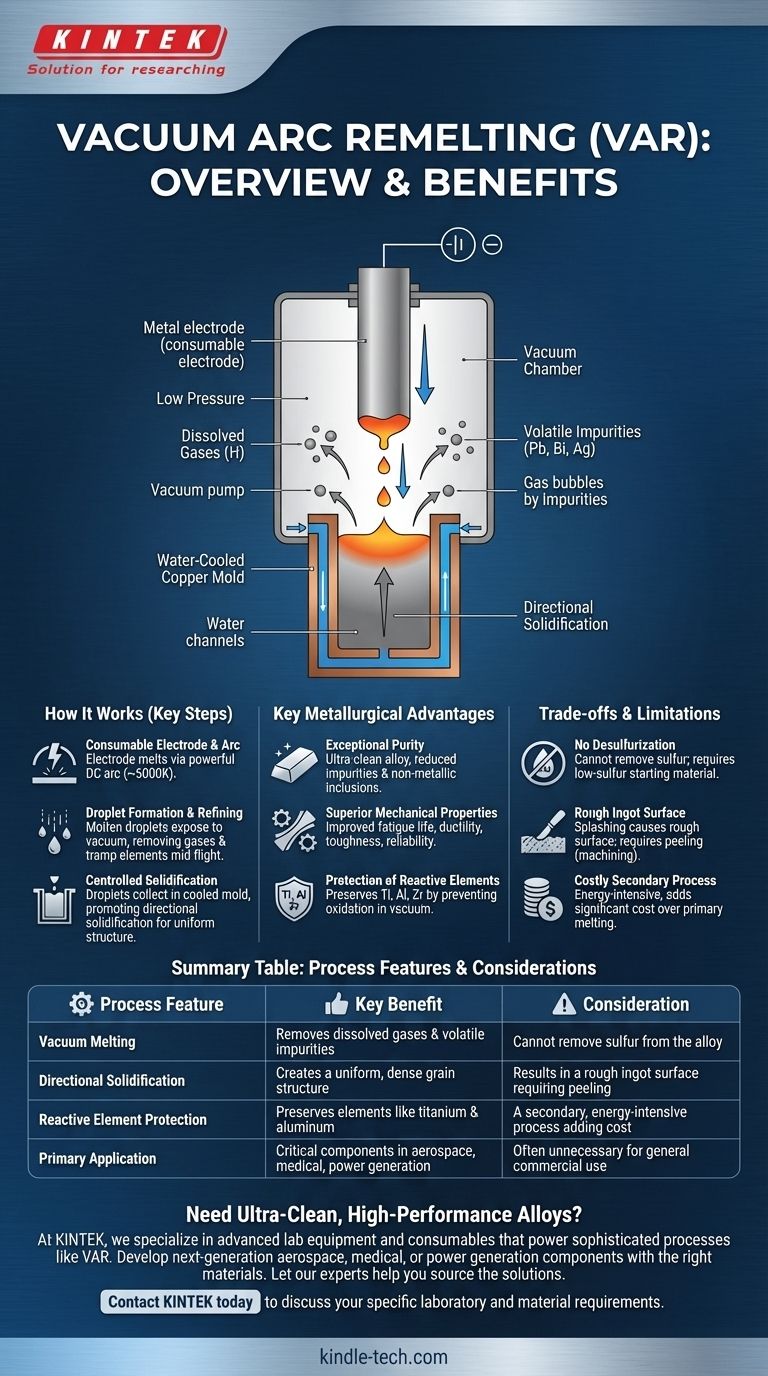

How the VAR Process Achieves Purification

The effectiveness of VAR lies in its combination of high heat and a controlled vacuum environment, which drives a series of physical and chemical refining reactions.

The Consumable Electrode and Arc

The process begins with a solid cylinder of the alloy to be refined, known as a consumable electrode. This electrode is suspended inside a vacuum furnace and functions as the negative terminal (cathode) in a high-power DC circuit.

An electric arc is struck between the bottom tip of the electrode and a small amount of starter material in the base of the water-cooled copper mold. The intense heat of the arc, reaching nearly 5000K, melts the tip of the electrode.

Droplet Formation and Vacuum Refining

As the electrode melts, droplets of liquid metal form and detach. During their fall through the vacuum, these superheated droplets are exposed to the low-pressure environment.

This exposure is critical. The vacuum helps pull out dissolved gases like hydrogen and volatile, low-melting-point tramp elements such as lead, bismuth, and silver, effectively purifying the metal mid-flight.

Controlled Solidification in the Mold

The purified droplets collect in a molten pool at the bottom of the water-cooled copper mold. Because the mold is actively cooled, solidification begins immediately at the mold wall and progresses upward and inward.

This directional solidification is crucial for producing a uniform and refined crystal structure. It minimizes chemical segregation and internal defects like shrinkage porosity, resulting in an ingot that is dense and chemically homogenous.

Key Metallurgical Advantages

The unique conditions of the VAR process deliver distinct benefits that are unattainable with conventional air-melting techniques.

Exceptional Purity and Cleanliness

By preventing contamination from air (oxygen and nitrogen) and actively removing dissolved gases and volatile metals, VAR produces an ultra-clean alloy. This reduction in impurities and non-metallic inclusions is the primary reason for its use.

Superior Mechanical Properties

The fine, uniform grain structure created by controlled solidification directly enhances the material's performance. VAR-processed alloys exhibit improved fatigue life, ductility, toughness, and overall reliability under stress.

Protection of Reactive Elements

For special alloys, VAR is essential for preserving precise amounts of highly reactive elements like titanium and aluminum. In a conventional furnace, these elements would burn off and be lost through oxidation. The vacuum environment protects them, ensuring the final chemistry meets exact specifications.

Understanding the Trade-offs and Limitations

While powerful, VAR is not a universal solution. Its benefits come with specific operational constraints and costs.

No Desulfurization Capability

The VAR process cannot remove sulfur. Therefore, the consumable electrode used as the starting material must already have a very low sulfur content. This places a significant constraint on the initial material selection.

Rough Ingot Surface

The melting process often involves splashing, which results in a rough, porous, and chemically inconsistent surface on the final ingot. This outer layer must be machined away—a process called surface peeling—before the ingot can be used for forging or other hot working, adding cost and reducing material yield.

A Costly Secondary Process

VAR is an energy-intensive, secondary refining step. It adds significant cost compared to primary melting methods and is therefore reserved for applications where the highest possible material quality is a non-negotiable requirement.

When to Specify a VAR Material

Choosing a VAR-processed alloy is a decision driven by the end-use application's performance and safety demands.

- If your primary focus is ultimate reliability and fatigue life: Specify VAR for critical components in aerospace, power generation, or medical implants where material failure would be catastrophic.

- If your primary focus is manufacturing with reactive alloys: Use VAR to produce specialty metals containing precise amounts of titanium, zirconium, or aluminum without losing them to oxidation.

- If your primary focus is general structural or commercial use: VAR is almost always unnecessary. A conventional air-melted or vacuum-degassed material will provide sufficient performance at a much lower cost.

Understanding the principles of VAR empowers you to specify the exact material quality required to meet your most demanding engineering challenges.

Summary Table:

| Process Feature | Key Benefit | Consideration |

|---|---|---|

| Vacuum Melting | Removes dissolved gases & volatile impurities | Cannot remove sulfur from the alloy |

| Directional Solidification | Creates a uniform, dense grain structure | Results in a rough ingot surface requiring peeling |

| Reactive Element Protection | Preserves elements like titanium & aluminum | A secondary, energy-intensive process adding cost |

| Primary Application | Critical components in aerospace, medical, and power generation | Often unnecessary for general commercial use |

Need ultra-clean, high-performance alloys for your critical applications?

At KINTEK, we specialize in the advanced lab equipment and consumables that power sophisticated processes like Vacuum Arc Remelting. Whether you are developing next-generation aerospace components, life-saving medical implants, or high-reliability power generation systems, the right materials are fundamental to your success.

Let our experts help you source the solutions you need to meet your most demanding engineering challenges. Contact KINTEK today to discuss your specific laboratory and material requirements.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- How thick is the plasma nitriding layer? Tailor Case Depth from 0.05mm to 0.5mm for Your Needs

- What advantages do fast-heating furnaces provide when brazing manganese-nickel alloys? Precision Thermal Control Guide

- What is the significance of vacuum heating for Li-IL in MOFs? Ensure Deep Dehydration & Battery Stability

- What are the factors of pyrolysis? Balancing Technical and Economic Levers for Success

- What is the temperature and time for quenching? Mastering the Critical Parameters for Hardening Metals

- What function does a laboratory vacuum furnace serve during the 150°C post-treatment of fluorinated carbon aerogels?

- Can brazing be used for ferrous metals? Yes, and here's how to ensure a strong joint.

- What precautions should be taken during annealing? Ensure Material Integrity and Performance