At its core, magnetron sputtering is a plasma-based physical vapor deposition (PVD) technique. It uses magnetically-confined plasma to bombard a material source, known as the "target," with a continuous stream of high-energy ions. This collision physically ejects atoms from the target, which then travel through a vacuum and deposit onto a substrate, forming an exceptionally dense, pure, and uniform thin film.

The critical innovation of magnetron sputtering is its use of a magnetic field to trap electrons near the target's surface. This dramatically increases the efficiency of the plasma, enabling high deposition rates at lower gas pressures, which is the fundamental key to creating higher-quality films.

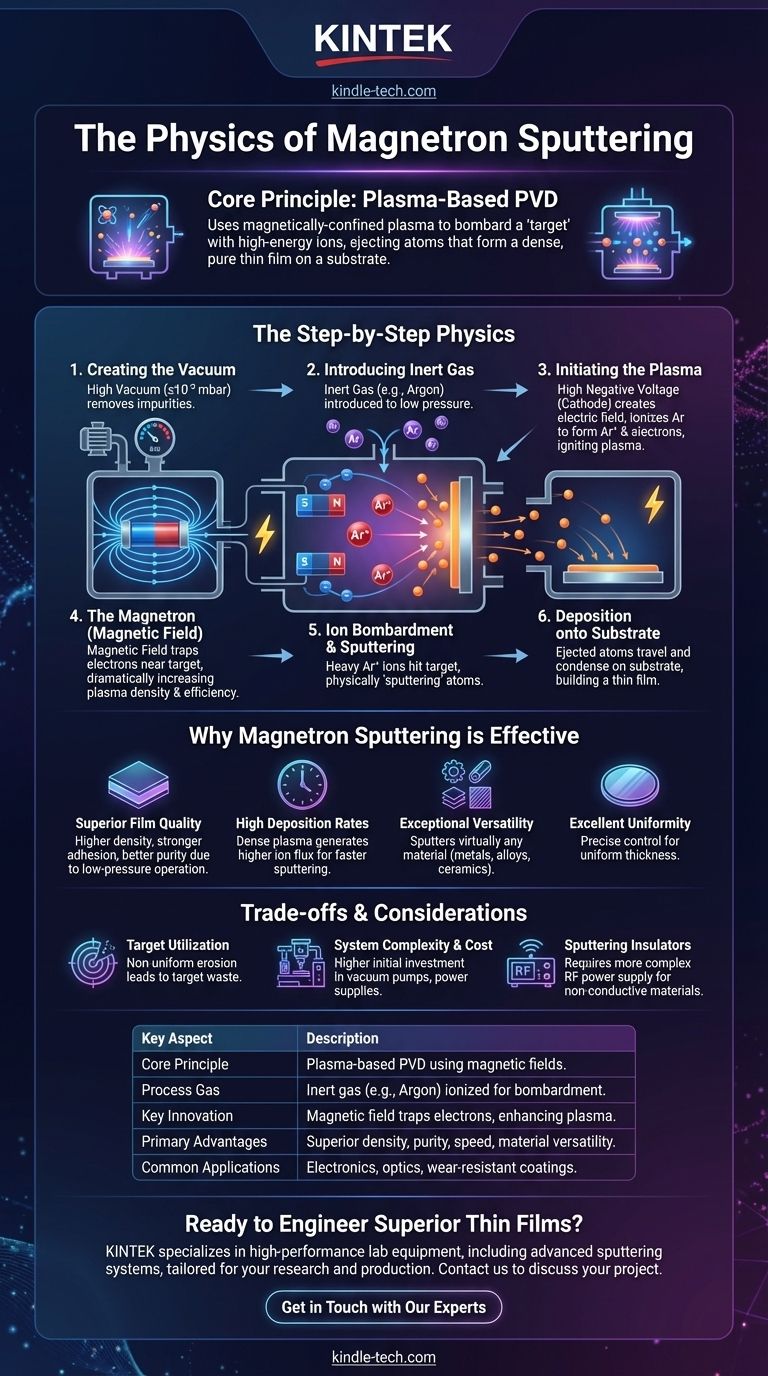

The Fundamental Physics: A Step-by-Step Breakdown

To understand how magnetron sputtering works, it's best to break it down into the sequence of physical events that occur inside the deposition chamber.

Step 1: Creating the Vacuum Environment

First, the process chamber is pumped down to a high vacuum (typically 10⁻³ mbar or lower). This crucial step removes residual gases like oxygen, water vapor, and other impurities that could contaminate the final film.

Step 2: Introducing the Inert Gas

An inert gas, most commonly Argon (Ar), is then introduced into the chamber, raising the pressure to a carefully controlled low level (around 10⁻¹ to 10⁻³ mbar). Argon is chosen because it is chemically non-reactive and has a relatively high atomic mass, making it effective for the bombardment process.

Step 3: Initiating the Plasma

A high negative DC or RF voltage is applied to the target material, which acts as the cathode. This creates a powerful electric field that accelerates stray electrons present in the gas.

These high-speed electrons collide with neutral Argon atoms, knocking an electron out of the atom's orbit. This event creates two new particles: a positively charged Argon ion (Ar⁺) and another free electron. This process repeats, creating a cascade that rapidly ignites and sustains a glowing plasma discharge.

Step 4: The Role of the Magnetic Field (The "Magnetron")

This is the defining step of the process. A set of powerful permanent magnets is placed behind the target. This creates a magnetic field that projects out in front of the target's surface.

This magnetic field traps the lightweight, fast-moving electrons in a spiral path very close to the target. By confining the electrons, their path length is dramatically increased, vastly raising the probability that they will collide with and ionize more Argon atoms. This creates a much denser and more stable plasma right where it is needed most.

Step 5: Ion Bombardment and Sputtering

The heavy, positively charged Argon ions (Ar⁺) are largely unaffected by the magnetic field but are strongly attracted to the high negative voltage of the target.

They accelerate directly into the target's surface with significant kinetic energy. This impact transfers momentum to the atoms of the target material, physically ejecting them or "sputtering" them off the surface.

Step 6: Deposition onto the Substrate

The ejected target atoms travel in a straight line through the low-pressure environment until they strike the substrate (the object being coated).

Upon arrival, they condense on the surface, gradually building up a thin film one atomic layer at a time. The high energy of these arriving atoms helps form very dense and strongly adhered films.

Why Magnetron Sputtering is So Effective

The underlying physics directly leads to the technique's primary advantages in industrial and research settings.

Superior Film Quality

Because the magnetic field makes the plasma so efficient, the process can be run at lower gas pressures. This means sputtered atoms are less likely to collide with gas molecules on their way to the substrate, allowing them to arrive with higher energy. This results in films with higher density, stronger adhesion, and better purity.

High Deposition Rates

The dense, magnetically-confined plasma generates a much higher flux of ions bombarding the target compared to simple diode sputtering. This translates directly into a faster sputtering rate and significantly reduced coating times, making it ideal for mass production.

Exceptional Material Versatility

Sputtering is a physical, not a chemical or thermal, process. It relies purely on momentum transfer. This means virtually any material can be sputtered, including high-melting-point metals, alloys, and even insulating ceramics (using RF power supplies).

Excellent Uniformity and Control

The process parameters—voltage, pressure, and gas flow—can be precisely controlled to achieve highly uniform and repeatable film thicknesses across large surface areas, which is critical for applications in electronics and optics.

Understanding the Trade-offs and Considerations

While powerful, the technique is not without its limitations. Objectivity requires acknowledging them.

Target Material Utilization

The magnetic field confines the plasma to a specific area, leading to non-uniform erosion of the target, often in a "racetrack" pattern. This means a significant portion of the expensive target material may not be used, which impacts cost-effectiveness.

System Complexity and Cost

A magnetron sputtering system requires a significant investment in vacuum pumps, high-voltage power supplies, magnetic assemblies, and process control systems. The initial capital cost is higher than for some simpler coating methods.

Sputtering Insulators

The basic DC sputtering process described above only works for electrically conductive targets. To deposit insulating materials like ceramics, a more complex and expensive Radio Frequency (RF) power supply is required to prevent a positive charge from building up on the target surface, which would otherwise stop the process.

Making the Right Choice for Your Goal

Understanding the physics allows you to align the technique with your specific application needs.

- If your primary focus is high-purity, dense coatings for electronics or optics: Magnetron sputtering is a superior choice due to its low-pressure operation and high-energy deposition.

- If your primary focus is depositing complex alloys with precise composition: The physical nature of sputtering ensures the material's stoichiometry is accurately transferred from the target to the film.

- If your primary focus is coating a simple shape with a low-melting-point metal at the lowest cost: A simpler technique like thermal evaporation might be a more economical alternative.

By understanding the interplay of plasma, electric fields, and magnetic confinement, you can leverage magnetron sputtering to achieve precisely engineered surfaces for the most demanding applications.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Plasma-based Physical Vapor Deposition (PVD) using magnetic fields to enhance efficiency. |

| Process Gas | Inert gas (typically Argon) ionized to create a plasma for bombarding the target material. |

| Key Innovation | Magnetic field traps electrons, creating a dense plasma for high deposition rates at low pressure. |

| Primary Advantages | Superior film density, purity, adhesion, high deposition rates, and exceptional material versatility. |

| Common Applications | Electronics, optics, wear-resistant coatings, and advanced materials research. |

Ready to engineer superior thin films for your research or production?

The precise control and high-quality results of magnetron sputtering are essential for advancing technology in semiconductors, renewable energy, and medical devices. At KINTEK, we specialize in providing high-performance lab equipment, including advanced sputtering systems and consumables, tailored to the exact needs of your laboratory.

Our experts can help you select the right system to achieve the dense, pure, and uniform coatings critical for your success. Contact us today to discuss your project and discover how KINTEK solutions can enhance your capabilities.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials