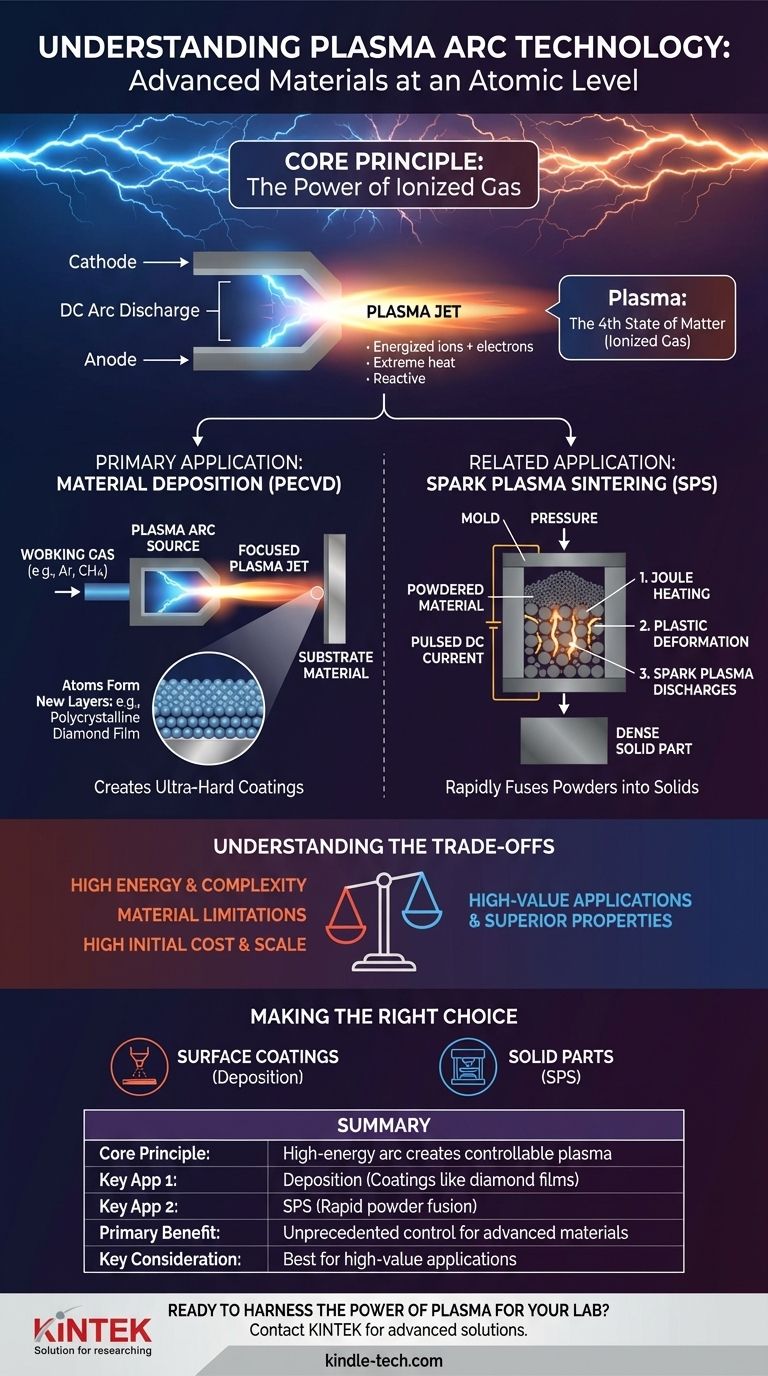

At its core, plasma arc technology is a process that uses a high-energy electrical discharge, or arc, to create a state of matter known as plasma. This superheated, ionized gas is then precisely directed to manipulate materials at an atomic level. This enables advanced manufacturing techniques, most notably for applying specialized coatings or for rapidly fusing powdered materials into a solid mass.

Plasma arc technology is not a single tool, but a powerful principle. It harnesses electricity to create a controlled, high-energy plasma jet, which can be used either to deposit new material onto a surface or to rapidly sinter powdered materials into dense, solid objects.

The Core Principle: Generating Plasma from an Arc

Plasma arc technology is fundamentally about energy conversion. It transforms electrical energy into thermal and kinetic energy by creating and controlling plasma.

What Is Plasma?

Plasma is often called the fourth state of matter, alongside solid, liquid, and gas. It is a gas that has been energized to the point that its atoms are stripped of their electrons, creating a mixture of charged ions and free electrons. This state makes plasma electrically conductive and highly reactive.

How an Electric Arc Creates Plasma

The process begins by creating a powerful DC arc discharge between two electrodes: a cathode and an anode. This arc is an intense, sustained electrical current flowing through a gas. The immense energy of the arc rapidly heats the gas to extreme temperatures.

This extreme heat ionizes the gas atoms, converting the gas into a high-temperature plasma. The working gas is effectively transformed into a controllable, high-energy tool.

The Role of Working Gases

The specific gas used, known as the working gas, determines the final outcome. Gases like Argon (Ar) provide an inert, high-energy plasma jet, while reactive gases like Methane (CH4) or Hydrogen (H2) can participate in chemical reactions to form new materials.

Primary Application: Material Deposition

One of the most common uses for plasma arc technology is the deposition of thin films and coatings. This process is often called Plasma-Enhanced Chemical Vapor Deposition (PECVD) or, in this specific case, DC arc plasma injection.

Creating Ultra-Hard Coatings

A prime example is the creation of synthetic diamond films. By using a working gas mixture containing methane (CH4), the plasma arc provides the energy needed to break the methane molecules apart.

The Deposition Process Explained

The generated plasma is ejected from the arc source at very high speed, driven by gas pressure and electromagnetic fields. This creates a focused plasma jet that is aimed at a target material, known as the substrate.

How Atoms Form New Layers

When the high-energy plasma hits the substrate, the carbon atoms from the methane are deposited onto the surface. The energy and conditions are so precise that these carbon atoms bond together to form a strong, polycrystalline diamond film, creating a surface with exceptional hardness and durability.

Another Key Application: Spark Plasma Sintering (SPS)

While not always using a visible "arc," Spark Plasma Sintering (SPS) is a related technology that uses plasma effects to rapidly fuse powders into a solid.

Fusing Powders into Solids

SPS is a rapid prototyping method used to create dense, solid parts from a starting powder. The powder is placed into a mold, and a high-amperage, pulsed DC current is passed directly through it.

How SPS Works

This process combines three key effects. First, Joule heating from the current rapidly heats the powder particles. Second, high pressure is applied to promote plastic deformation. Third, the pulsed current generates spark plasma discharges between particles, cleaning their surfaces and accelerating fusion.

Why It's Faster Than Traditional Methods

Compared to traditional hot-press sintering, which relies on external heating, SPS heats the material directly and internally. This dramatic efficiency allows for much faster sintering times and often results in materials with superior properties.

Understanding the Trade-offs

While powerful, plasma arc technologies are not a universal solution. Understanding their limitations is critical for proper application.

High Energy, High Complexity

These processes involve extreme temperatures and high electrical energies, requiring sophisticated equipment and precise control systems. Variables like gas flow rate, current, voltage, and pressure must be managed carefully to achieve the desired result.

Material and Substrate Limitations

The choice of working gas and substrate material is critical. The high temperatures can damage sensitive substrates, and not all materials can be effectively deposited or sintered using these methods.

High Initial Cost and Scale

The equipment for plasma arc deposition and SPS is specialized and expensive. This makes the technology best suited for high-value applications where the resulting material properties—such as hardness or density—justify the investment.

Making the Right Choice for Your Goal

To apply this technology, you must first define your manufacturing objective. The specific method you choose depends entirely on whether you are building on top of a material or building with a material.

- If your primary focus is creating thin films or surface coatings: You will use a plasma deposition technique to direct a jet of reactive plasma onto a substrate.

- If your primary focus is rapidly creating dense, solid parts from powder: You will use Spark Plasma Sintering (SPS) to pass a pulsed current directly through the powdered material under pressure.

Ultimately, plasma arc technology gives engineers unprecedented control over matter, enabling the creation of advanced materials that were previously impossible to fabricate.

Summary Table:

| Aspect | Description |

|---|---|

| Core Principle | Uses a high-energy electric arc to create a controllable, ionized gas (plasma). |

| Key Application 1 | Material Deposition (PECVD): Creates ultra-hard coatings like diamond films on substrates. |

| Key Application 2 | Spark Plasma Sintering (SPS): Rapidly fuses powdered materials into dense, solid parts. |

| Primary Benefit | Unprecedented control over matter for creating advanced materials with superior properties. |

| Key Consideration | High initial cost and complexity; best suited for high-value applications. |

Ready to Harness the Power of Plasma for Your Lab?

Plasma arc technology enables the creation of advanced materials with exceptional properties. Whether your goal is applying ultra-hard, wear-resistant coatings or rapidly prototyping dense components from powder, having the right equipment is critical.

KINTEK specializes in advanced lab equipment, including systems for plasma-enhanced processes. We can help you identify the right technology to achieve your material science goals, improve your research outcomes, and accelerate your development cycle.

Contact us today to discuss how our solutions can empower your work. Let's turn your material challenges into breakthroughs.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Can aluminum be sintered? Overcome the Oxide Barrier for Complex, Lightweight Parts

- What is the SPS process of spark plasma sintering? A Guide to Rapid, Low-Temperature Densification

- What is the difference between hot press and SPS? Choose the Right Sintering Method for Your Lab

- What are the steps in spark plasma sintering? Achieve Rapid, Low-Temperature Densification

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication