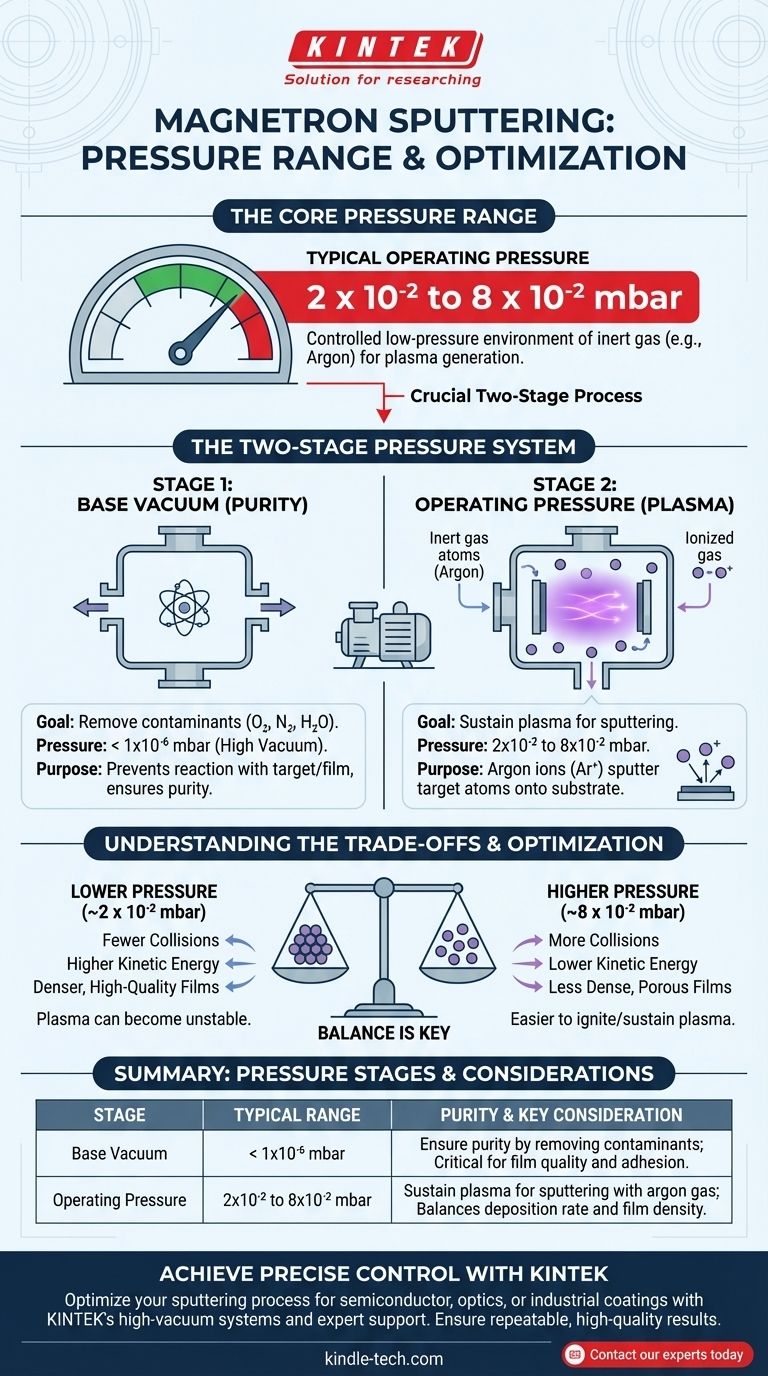

In magnetron sputtering, the typical operating pressure is a controlled low-pressure environment, generally ranging from 2 x 10⁻² to 8 x 10⁻² mbar. This specific pressure of an inert gas, like argon, is only introduced after the chamber has been pumped down to a much higher base vacuum to ensure a pure, contaminant-free environment for deposition.

The key is to understand that magnetron sputtering involves two distinct pressure regimes: a very high base vacuum to ensure purity, followed by a slightly higher operating pressure created by a working gas to generate the plasma needed for sputtering.

The Two-Stage Pressure System Explained

The pressure inside a sputtering chamber isn't a single setting but a carefully controlled two-step process. Mistaking the base vacuum for the operating pressure is a common point of confusion.

Stage 1: Achieving High Vacuum (Base Pressure)

Before any sputtering can begin, the deposition chamber must be evacuated to a high vacuum. This initial "base pressure" is often less than one ten-millionth of atmospheric pressure.

The sole purpose of this step is purity. By removing residual gases like oxygen, nitrogen, and water vapor, you prevent them from reacting with the target material or being incorporated into the deposited film, which would compromise its electrical, optical, or mechanical properties.

Stage 2: Introducing the Working Gas (Operating Pressure)

Once a sufficiently high vacuum is achieved, a controlled flow of a high-purity inert gas, typically argon, is introduced into the chamber. This raises the pressure to the specific operating range of 2 x 10⁻² to 8 x 10⁻² mbar.

This working gas serves as the fuel for the sputtering process. A high voltage is applied, which ionizes the argon gas atoms, creating a stable plasma. These positively charged argon ions are then accelerated into the negatively charged target material, dislodging atoms that then travel to and coat the substrate.

Why This Specific Pressure Range Matters

This pressure range represents a critical balance. It must be high enough to provide sufficient argon atoms to sustain a stable plasma and generate an adequate sputtering rate.

However, it must also be low enough to ensure that the sputtered atoms can travel from the target to the substrate with minimal collisions with the gas atoms along the way. This relatively long "mean free path" is essential for creating dense, high-quality films.

Understanding the Trade-offs

The choice of operating pressure within this range is not arbitrary; it directly impacts the deposition process and the final film quality.

The Effect of Higher Pressure

Operating at the higher end of the range (closer to 8 x 10⁻² mbar) can make it easier to ignite and sustain the plasma.

However, it also increases the chance of sputtered atoms colliding with gas atoms. This can reduce the energy of the depositing atoms, potentially leading to films that are less dense or have a more porous structure.

The Effect of Lower Pressure

Operating at the lower end (closer to 2 x 10⁻² mbar) results in fewer gas-phase collisions. The sputtered atoms arrive at the substrate with higher kinetic energy, which generally promotes the growth of denser, higher-quality films.

The primary challenge is that the plasma can become unstable or difficult to sustain at very low pressures, leading to an inconsistent or failed deposition run.

How to Optimize Pressure for Your Goal

Controlling the working gas pressure is a primary lever for tuning the properties of your deposited thin film.

- If your primary focus is achieving the highest film density and purity: Aim for the lowest possible base pressure and operate at the lower end of the working pressure range where your plasma remains stable.

- If your primary focus is a stable process with a reasonable deposition rate: Operating in the middle of the typical pressure range is often the most reliable starting point for a wide variety of materials and applications.

Ultimately, mastering pressure control is fundamental to achieving repeatable, high-quality results in magnetron sputtering.

Summary Table:

| Pressure Stage | Typical Range | Purpose | Key Consideration |

|---|---|---|---|

| Base Vacuum | < 1x10⁻⁶ mbar | Ensure purity by removing contaminants | Critical for film quality and adhesion |

| Operating Pressure | 2x10⁻² to 8x10⁻² mbar | Sustain plasma for sputtering with argon gas | Balances deposition rate and film density |

Achieve precise control over your sputtering process with KINTEK.

Whether you're developing advanced coatings for semiconductors, optics, or industrial tools, the right pressure settings are crucial for film density, purity, and performance. KINTEK's range of high-vacuum sputtering systems and expert support helps you optimize every parameter for repeatable, high-quality results.

Ready to enhance your thin film deposition? Contact our experts today to discuss your specific application needs and discover how KINTEK's lab equipment solutions can drive your research and production forward.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems