At its core, pressureless sintering is a process for compacting powdered materials into a solid mass using only high temperatures, without the application of any external mechanical pressure. The entire process relies on thermal energy to drive atomic diffusion, causing the individual particles to fuse together and reduce the empty space between them.

While many manufacturing processes rely on force, the key principle of pressureless sintering is its deliberate simplicity. It leverages a material's inherent ability to densify under heat, making it a foundational technique whose trade-offs become clear when compared to more complex, pressure-assisted methods.

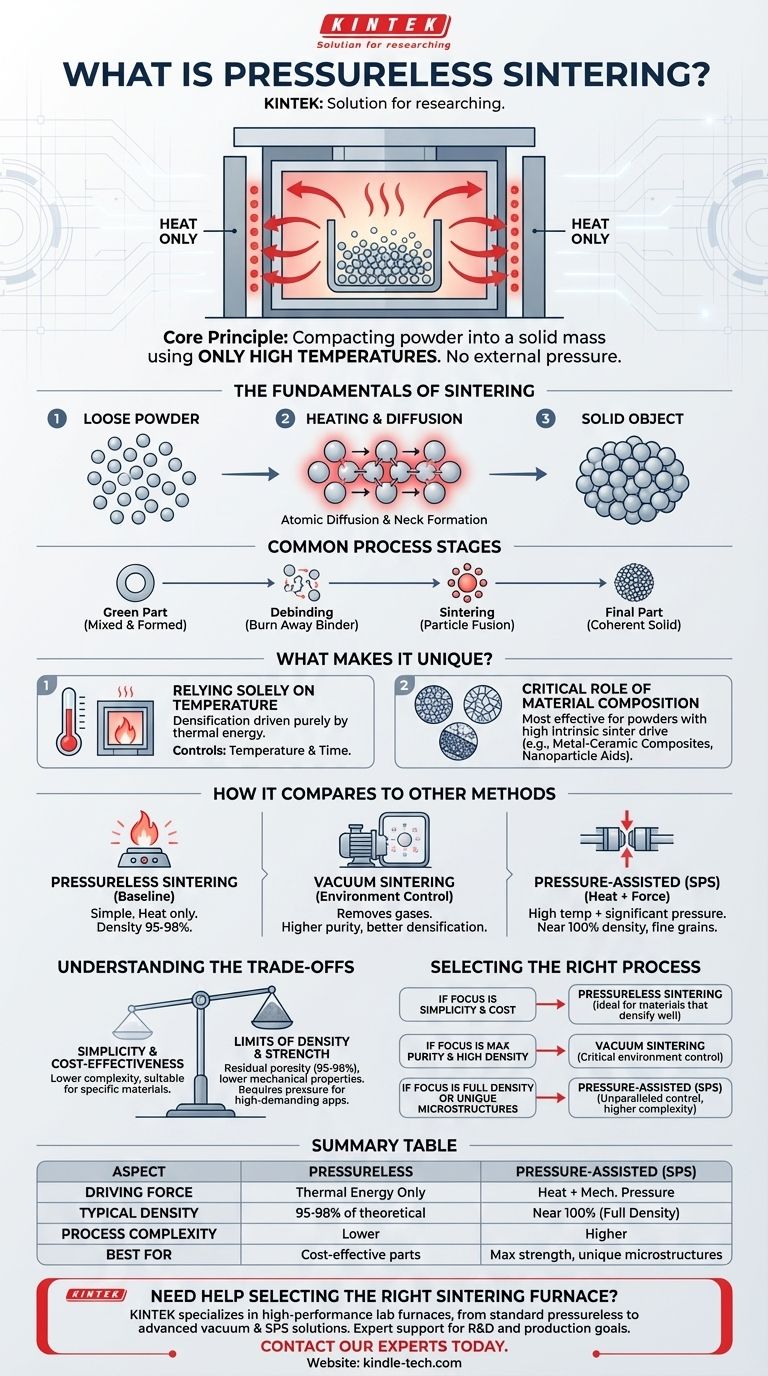

The Fundamentals of Sintering

To understand pressureless sintering, it's first necessary to grasp the basic mechanism that turns a loose powder into a dense, solid object.

How Powder Becomes Solid

Sintering works by heating a material to a temperature below its melting point. At this elevated temperature, the atoms at the contact points between powder particles become more mobile.

This atomic diffusion allows the particles to form chemical bonds and "necks" between them, gradually closing the pores and voids in the material. The result is a densified, solid component.

The Common Stages of the Process

For many applications, the process begins by mixing the primary powder with a temporary binder, such as wax or a polymer.

First, this blend is formed into the desired preliminary shape, often called a "green part." Next, the part is heated in a furnace to burn away the binder. Finally, the temperature is raised to the sintering point, where the primary particles fuse together into a coherent solid.

What Makes Pressureless Sintering Unique?

Pressureless sintering is defined by what it lacks: external force. This makes it distinct from other advanced consolidation techniques.

Relying Solely on Temperature

The driving force for densification in this method is purely thermal. The process relies on carefully controlling the furnace temperature and the duration of the heating cycle to achieve the desired level of particle fusion and density.

The Critical Role of Material Composition

This technique is not suitable for all materials. It is most effective for powders that have a high intrinsic drive to sinter, such as certain metal-ceramic composites or materials enhanced with nanoparticle sintering aids.

These formulations are specifically engineered to densify efficiently without needing to be physically squeezed together.

How It Compares to Other Sintering Methods

Pressureless sintering is the baseline. Understanding how other methods modify this baseline reveals why they are used.

Contrast with Vacuum Sintering

Vacuum sintering is not a fundamentally different process but rather sintering performed in a controlled environment. By removing atmospheric gases from the furnace, a vacuum prevents oxidation and helps pull out gases released from the material itself.

This results in a final product with higher purity, better densification, and more stable performance. Vacuum conditions can be applied to pressureless sintering or combined with pressure-assisted methods.

Contrast with Pressure-Assisted Sintering (SPS)

Spark Plasma Sintering (SPS) is a modern technique that applies both high temperature and significant mechanical pressure. It uses a pulsed electric current that flows directly through the powder and die, creating incredibly rapid heating.

The combination of direct current and external pressure forces particles together quickly. This speed inhibits the natural growth of material grains, enabling the creation of components with unique, fine-grained microstructures that are impossible to achieve with slower, pressureless methods.

Understanding the Trade-offs

The primary advantage of pressureless sintering—its simplicity—is also the source of its main limitations.

The Limits of Full Densification

Without external force to squeeze particles together, pressureless sintering may struggle to eliminate all porosity. For many materials, it can be difficult to achieve a density above 95-98% of the theoretical maximum.

This residual porosity can impact mechanical properties like strength and hardness, making the process unsuitable for the most demanding structural applications.

When Pressure Becomes Necessary

For materials that sinter poorly or for components where near-perfect density is non-negotiable, pressure-assisted sintering is required. Methods like Hot Pressing or SPS physically close the remaining pores, overcoming the material's natural resistance to densification.

Selecting the Right Sintering Process

Your choice of sintering method depends entirely on the material you are working with and the final properties you need to achieve.

- If your primary focus is process simplicity and cost-effectiveness: Pressureless sintering is often the ideal choice, especially for materials engineered to densify well with heat alone.

- If your primary focus is achieving maximum purity and high density: Vacuum sintering is a critical environmental control that prevents contamination and is often necessary for high-performance materials.

- If your primary focus is achieving full density or creating unique microstructures: Advanced, pressure-assisted methods like SPS provide unparalleled control, justifying their higher complexity and cost for cutting-edge applications.

Ultimately, choosing the right method is about matching the process mechanics—heat, pressure, and environment—to your specific material and performance goals.

Summary Table:

| Aspect | Pressureless Sintering | Pressure-Assisted (e.g., SPS) |

|---|---|---|

| Driving Force | Thermal energy only | Heat + Mechanical pressure |

| Typical Density | 95-98% of theoretical | Near 100% (Full density) |

| Process Complexity | Lower | Higher |

| Best For | Cost-effective parts, suitable materials | Maximum strength, unique microstructures |

Need help selecting the right sintering furnace for your materials?

KINTEK specializes in high-performance lab furnaces for all your sintering needs, from standard pressureless systems to advanced vacuum and SPS solutions. Our expertise ensures you get the precise temperature control and environment required to achieve your desired material properties.

Contact our experts today to discuss how we can support your R&D or production goals with the ideal laboratory equipment.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification

- What is vacuum sintering? Achieve Unmatched Purity and Performance for Advanced Materials

- What is sintering reaction? Transform Powders into Dense Solids Without Melting