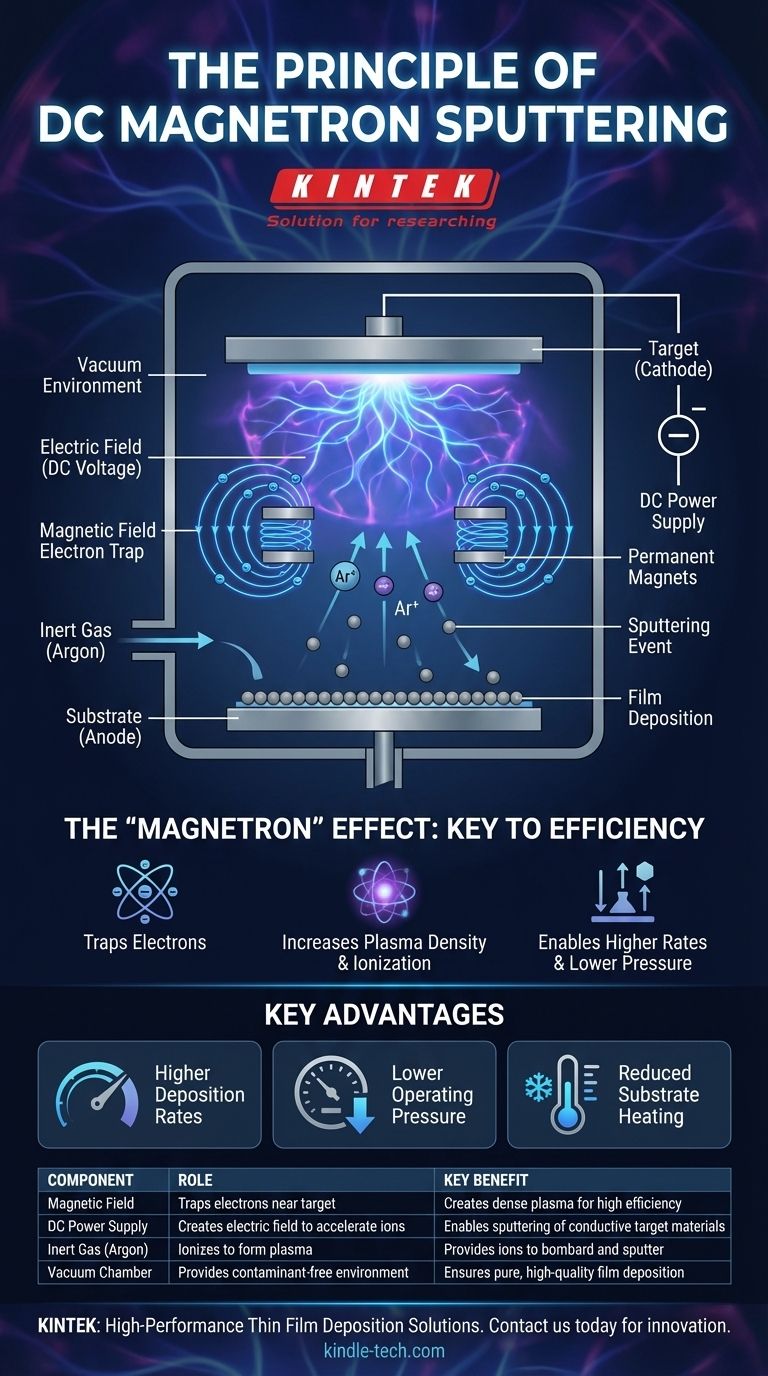

In essence, DC magnetron sputtering is a highly efficient vacuum coating process used to deposit thin films of material onto a surface. It works by creating a magnetically confined plasma from an inert gas, like argon. This plasma generates positive ions that are accelerated into a negatively charged material source, called a target, knocking atoms loose. These ejected atoms then travel through the vacuum and condense onto a substrate, building a high-quality film layer by layer.

The core principle is not just the sputtering itself, but the use of a strategically placed magnetic field to trap electrons near the target. This simple addition dramatically increases the plasma's density and ionization efficiency, enabling higher deposition rates at lower pressures and temperatures than other sputtering methods.

The Core Components of the Process

To understand the principle, we must first look at the fundamental setup inside the sputtering chamber.

The Vacuum Environment

The entire process occurs in a high-vacuum chamber, typically pumped down to very low pressures. This is critical to remove air and other contaminants that could react with and compromise the film. It also ensures the sputtered atoms can travel freely from the target to the substrate without colliding with other gas molecules.

The Target and Substrate

The target is a plate made of the material you wish to deposit (e.g., titanium, copper, aluminum). It is connected to a high-voltage DC power supply and acts as the cathode (negative electrode). The substrate is the object to be coated and is typically placed on the anode (positive or grounded electrode).

The Inert Gas (Argon)

A small, precisely controlled amount of an inert gas, almost always argon (Ar), is introduced into the chamber. Argon is used because it is chemically non-reactive and has a suitable atomic mass to efficiently dislodge atoms from the target upon impact.

The Electric Field (The "DC" part)

A strong Direct Current (DC) voltage, often several hundred volts, is applied between the cathode (target) and the anode. The target is held at a high negative potential, creating a powerful electric field that will accelerate charged particles.

The "Magnetron" Effect: The Key to Efficiency

The "magnetron" in the name refers to the specific use of magnets, which is the crucial innovation that makes the process so effective.

Creating the Plasma (Glow Discharge)

The high voltage applied across the argon gas strips electrons from some of the argon atoms. This creates a mixture of positively charged argon ions (Ar+) and free electrons, which is known as a plasma or "glow discharge."

The Problem with Simple Diode Sputtering

In a simple system without magnets, the light, negatively charged electrons are rapidly drawn to the positive anode. The plasma is therefore thin and unstable, requiring high gas pressures and voltages to sustain. This makes the process slow, inefficient, and prone to overheating the substrate.

How Magnets Trap Electrons

In magnetron sputtering, permanent magnets are placed behind the target. This creates a closed magnetic field that projects out in front of the target's surface. As electrons are drawn toward the anode, this magnetic field exerts a force (the Lorentz force) that traps them, forcing them into a long, spiraling path directly above the target.

The Impact of Trapped Electrons

These trapped electrons are the key to the entire process. By dramatically increasing their path length, their probability of colliding with and ionizing neutral argon atoms skyrockets. This creates a cascade effect, generating a very dense, stable plasma precisely where it is needed most—right in front of the target.

From Ion Bombardment to Film Deposition

With a dense plasma established, the final steps of film growth can occur rapidly.

The Sputtering Event

The dense cloud of positively charged Ar+ ions is now strongly accelerated by the powerful negative electric field of the target. They bombard the target surface with high kinetic energy. This impact is not a chemical or thermal process but a pure momentum transfer, physically knocking or "sputtering" atoms from the target material.

Deposition onto the Substrate

These newly liberated, electrically neutral target atoms travel through the vacuum in straight-line paths. When they reach the substrate, they condense on its surface, gradually building up a thin, uniform, and dense film.

Understanding the Key Advantages

The magnetron's ability to create a dense plasma provides three primary advantages over less advanced sputtering techniques.

Higher Deposition Rates

A denser plasma means far more Ar+ ions are available to bombard the target. This significantly increases the rate of sputtering and, consequently, the speed at which the film grows on the substrate.

Lower Operating Pressure

Because the ionization process is so efficient, magnetron sputtering can operate at much lower argon pressures (1-10 mTorr) compared to diode sputtering (>50 mTorr). This results in fewer gas-phase collisions, leading to higher-purity films.

Reduced Substrate Heating

The magnetic field confines the high-energy electrons to the target region, preventing them from bombarding and heating the substrate. This, combined with the ability to run at lower voltages, makes the process ideal for coating temperature-sensitive materials like plastics, polymers, and complex electronics.

How This Principle Is Applied

Understanding the role of each component clarifies when DC magnetron sputtering is the right choice for an application.

- If your primary focus is coating conductive materials: DC sputtering is ideal, as it relies on a conductive target to complete the electrical circuit and maintain the plasma.

- If your primary focus is deposition speed and throughput: The magnetron enhancement makes this one of the fastest and most economical PVD coating methods for large-scale production.

- If your primary focus is depositing high-quality, dense films: The low-pressure operation minimizes gas incorporation and creates films with excellent adhesion and structural integrity.

- If your primary focus is coating delicate substrates: The low operating temperature protects plastics, electronics, or other sensitive materials from thermal damage during deposition.

By mastering the interplay between the electric and magnetic fields, magnetron sputtering provides precise control over the creation of high-performance thin films.

Summary Table:

| Component | Role in the Process | Key Benefit |

|---|---|---|

| Magnetic Field | Traps electrons near the target | Creates a dense plasma for high efficiency |

| DC Power Supply | Creates electric field to accelerate ions | Enables sputtering of conductive target materials |

| Inert Gas (Argon) | Ionizes to form the plasma | Provides ions to bombard and sputter the target |

| Vacuum Chamber | Provides a contaminant-free environment | Ensures pure, high-quality film deposition |

Ready to enhance your lab's capabilities with precise thin film deposition?

KINTEK specializes in high-performance lab equipment, including DC magnetron sputtering systems designed for reliability and superior results. Whether you are coating semiconductors, creating optical layers, or developing new materials, our solutions deliver the high deposition rates and low-temperature operation you need.

Contact us today using the form below to discuss how our sputtering technology can advance your research and production. Let KINTEK be your partner in innovation.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the process of sintering steel industry? Optimize Blast Furnace Efficiency with Engineered Feed

- Can I vacuum my furnace? A DIY Guide to Safe and Effective HVAC Maintenance

- What is the process of sputter coating? A Step-by-Step Guide to Thin Film Deposition

- How long does it take to sinter? From Milliseconds to Days for Optimal Results

- Why is it necessary to preheat silica particles? Master the Prep for Defect-Free Zinc Alloy Composites

- How do you prepare a sample for XRF? Achieve Accurate and Reliable Analysis

- What is the disadvantage of plate frame filter press? High Labor Costs and Batch Process Downtime

- What is the conductivity of graphite? Understanding Its High Electrical & Thermal Properties