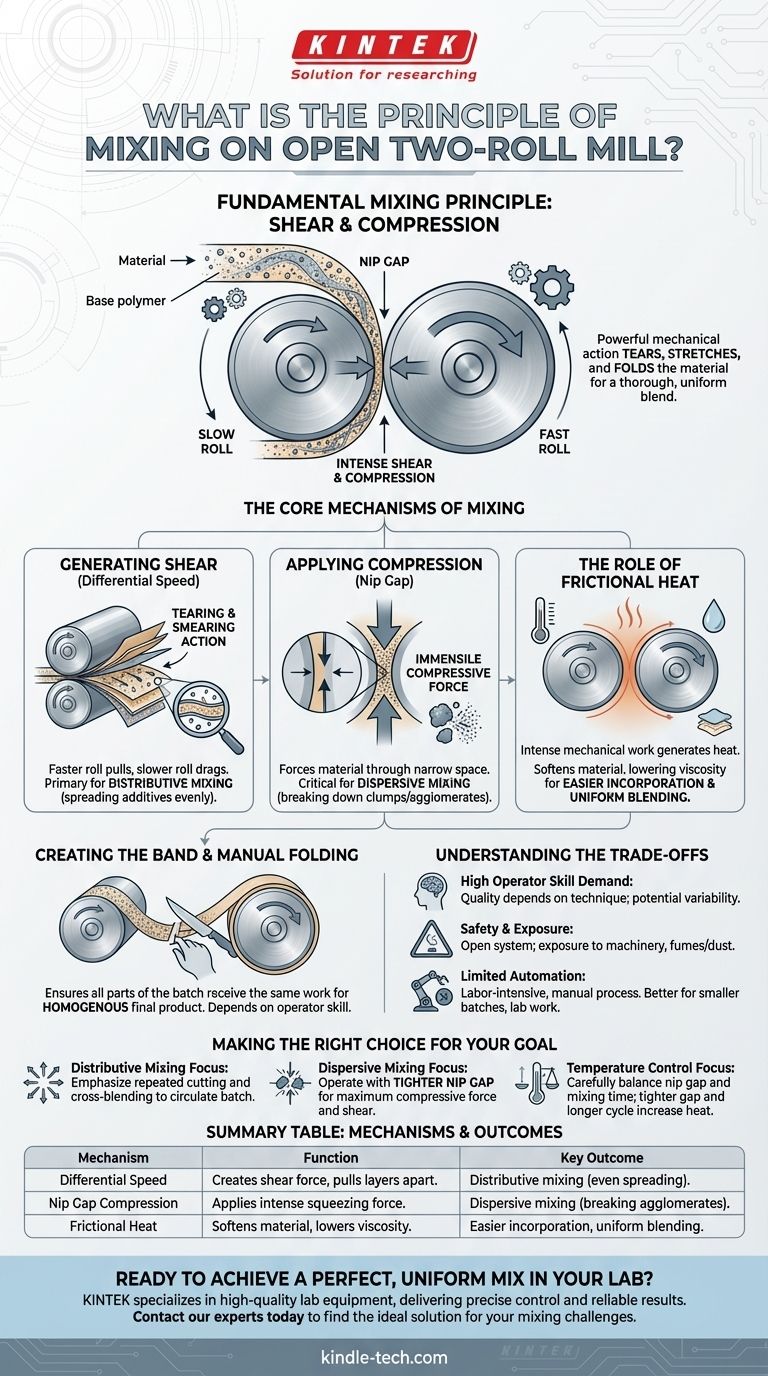

The fundamental mixing principle of a two-roll mill is the application of intense shear and compression to a material. This is achieved by passing the material through the narrow gap, or "nip," between two large steel rolls that rotate towards each other at different speeds. This powerful mechanical action tears, stretches, and folds the material, ensuring a thorough and uniform blend.

A two-roll mill achieves its mix not just by squeezing, but by creating a powerful shearing effect. The difference in roll speeds is the critical factor that pulls and tears material layers apart, while the narrow gap provides the compressive force needed to break down and disperse particles.

The Core Mechanisms of Mixing

To truly understand the process, it's essential to break down the distinct forces at play. Each mechanism serves a specific purpose in transforming raw ingredients into a homogenous compound.

Generating Shear with Differential Speed

The two rolls do not rotate at the same velocity. There is always a "slow" roll and a "fast" roll.

This differential speed is the primary source of shear force. As the material enters the nip, the faster roll pulls it forward while the slower roll drags it back, creating an intense tearing and smearing action between the layers of the material.

This action is highly effective for distributive mixing, which focuses on spreading particles of additives evenly throughout the polymer matrix.

Applying Compression at the Nip

The distance between the two rolls, known as the nip gap, is adjustable by the operator.

This narrow gap forces the material through a small space, subjecting it to immense compressive force. This squeezing action is critical for dispersive mixing—the process of breaking down clumps or agglomerates of additives (like carbon black or pigments) into their finest particles.

The Role of Frictional Heat

The intense mechanical work of shearing and compressing the material generates significant frictional heat.

This is not an unwanted side effect but a crucial part of the process. The heat softens the rubber or plastic, lowering its viscosity and making it more pliable. This softened state allows additives to be incorporated much more easily and uniformly.

Creating the Band and Manual Folding

During operation, the material will form a continuous sheet, or "band," that wraps around the faster roll.

To ensure all parts of the batch receive the same amount of work, the operator must manually use a knife to cut this band and fold it back into the nip repeatedly. This step is essential for guaranteeing a homogenous final product.

Understanding the Trade-offs

While powerful, the two-roll mill is a classic piece of machinery with inherent limitations that are important to recognize.

High Demand on Operator Skill

The quality and consistency of the final mix are heavily dependent on the skill of the operator. Their technique in cutting, folding, and managing the material band directly impacts the outcome, leading to potential batch-to-batch variability.

Safety and Exposure

As an "open" system, there are significant safety considerations. Operators are in close proximity to powerful rotating machinery and can be exposed to fumes or dust generated from the material being mixed.

Limited Automation

Compared to modern internal mixers (like a Banbury mixer), the two-roll mill is a labor-intensive, manual process. It is generally better suited for smaller batches, laboratory work, or situations requiring precise visual control over the mix.

Making the Right Choice for Your Goal

Controlling the outcome on a two-roll mill means understanding how to manipulate its key variables to achieve your specific objective.

- If your primary focus is distributive mixing (spreading additives evenly): Emphasize repeated cutting and cross-blending of the material band to ensure all parts of the batch are circulated through the nip.

- If your primary focus is dispersive mixing (breaking down tough particle clumps): Operate with a tighter nip gap to maximize compressive force and increase the local shear rate on the material.

- If your primary focus is controlling material temperature: Carefully balance the nip gap setting and mixing time, as a tighter gap and longer cycle will both dramatically increase heat buildup.

By mastering the interplay between roll speed, nip gap, and manual technique, you can effectively control the mixing process to achieve your desired compound properties.

Summary Table:

| Mechanism | Function | Key Outcome |

|---|---|---|

| Differential Speed | Creates shear force by pulling material layers apart. | Distributive mixing (even spreading of particles). |

| Nip Gap Compression | Applies intense squeezing force in the narrow roll gap. | Dispersive mixing (breaking down agglomerates). |

| Frictional Heat | Softens the material, lowering viscosity. | Easier incorporation and uniform blending of additives. |

Ready to achieve a perfect, uniform mix in your lab? The principles of a two-roll mill are foundational for material processing. KINTEK specializes in high-quality lab equipment, including mills and mixers, designed to deliver precise control and reliable results for your laboratory needs. Contact our experts today to find the ideal solution for your mixing challenges and enhance your R&D or quality control processes.

Visual Guide

Related Products

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Powerful Plastic Crusher Machine

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

People Also Ask

- What is the pyrolysis temperature of rubber? Control the Process to Maximize Your Output

- What are the disadvantages of blown film extrusion? Overcoming Precision and Speed Limitations

- What are the three types of rolling mills? A Guide to Boosting Your Metal Production Efficiency

- Why is a roller press machine required for CuMH solid-state membranes? Expert Insights on Flexible Electrolyte Forming

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts

- What does a blown film machine do? Transform Plastic Pellets into Versatile Film

- What does vulcanizing a tire do? Achieve a Permanent, Structural Tire Repair

- What is the mixing process of rubber? Master the Stages for Superior Compound Quality