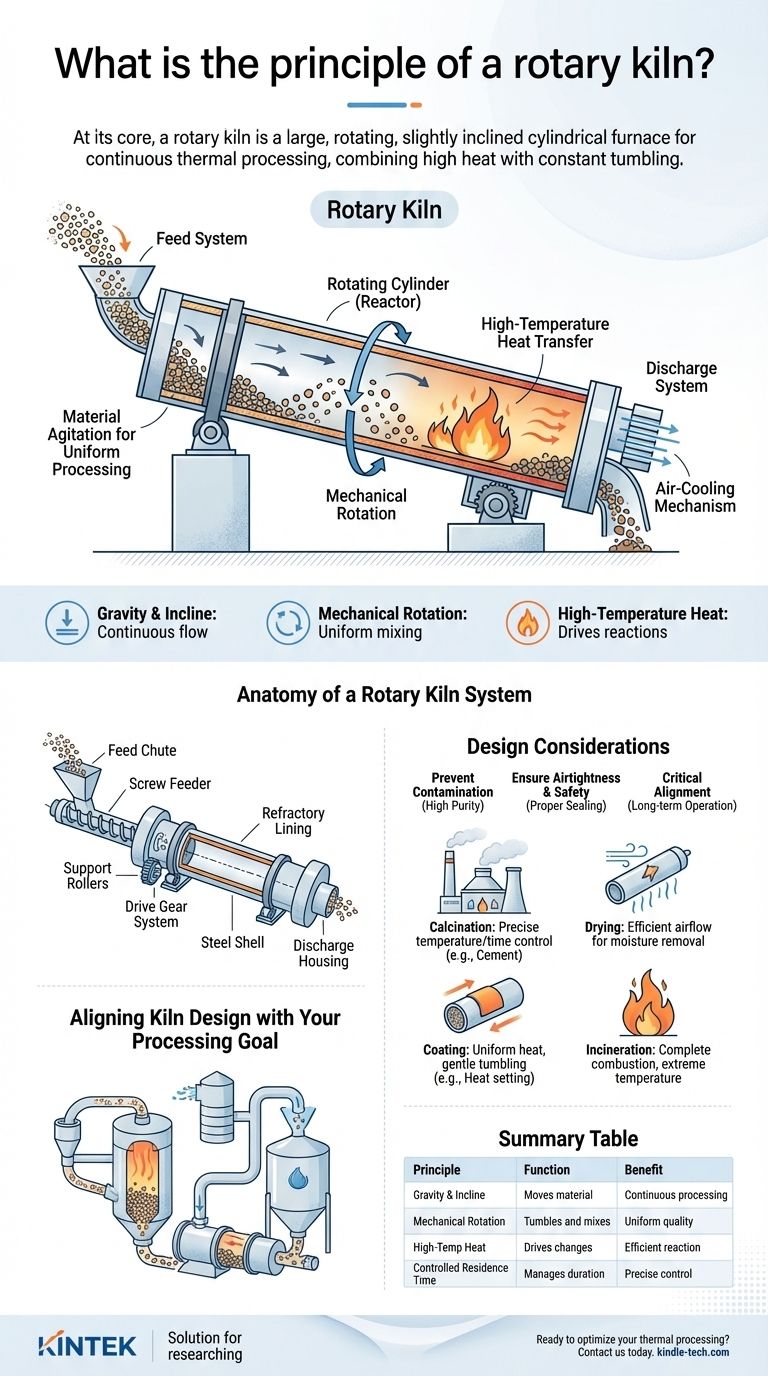

At its core, a rotary kiln is a large, rotating, slightly inclined cylindrical furnace used for the continuous thermal processing of solid materials. It combines high heat with constant tumbling motion, causing materials to undergo a physical change or chemical reaction as they travel from the upper feed end to the lower discharge end. This elegant principle allows it to function as a dryer, calcinator, incinerator, and reactor in a single, efficient system.

The genius of the rotary kiln lies in its masterful use of three simple principles: gravity, mechanical rotation, and high-temperature heat transfer. This combination ensures that bulk solids are heated uniformly and processed continuously, solving a fundamental challenge in large-scale material manufacturing.

The Fundamental Mechanism: Heat, Rotation, and Gravity

The operation of a rotary kiln is governed by a straightforward yet powerful interplay of physical forces and thermal energy. Understanding this core mechanism is key to appreciating its versatility.

The Role of Inclination and Rotation

A rotary kiln is always positioned at a slight angle to the horizontal. This incline is critical, as it uses gravity to move material through the cylinder.

As the kiln rotates slowly on its axis, the material inside is lifted up the side of the cylinder until the angle of repose is exceeded. The material then tumbles and slides down to the bottom, mixing as it goes. Each rotation advances the material bed slightly further down the incline, ensuring a continuous flow from input to output.

The Principle of Heat Transfer

The kiln is fundamentally a heat exchanger, designed to operate at extremely high temperatures. Heat is applied to the material to drive a specific process, such as drying, a chemical transformation, or combustion.

Modern kilns often feature 360° heater placement, which guarantees even and efficient heat transmission to the material bed as it tumbles. The system allows for a precise heat pattern to be set, matching the exact thermal requirements of the product being fired.

Material Agitation for Uniform Processing

The constant tumbling motion is not just for transport; it is essential for product quality. As the material tumbles, it continuously exposes new surfaces to the heat source.

This agitation ensures every particle is processed evenly, preventing hot spots and resulting in a highly consistent and uniform final product.

Anatomy of a Rotary Kiln System

A rotary kiln is the heart of a larger processing system. Each component is engineered to handle high temperatures and abrasive materials reliably.

The Feed System

Raw material is introduced at the higher end of the kiln through a feed chute. This is often done with a quantitative screw feeder (single, double, or shaftless) to ensure a controlled and consistent flow rate.

This feed component is typically made from a heat-resistant alloy and is designed to be robust, minimizing the chance of blockages or material build-up.

The Rotating Cylinder (Reactor)

The main body is a long, refractory-lined steel cylinder. It rotates on support rollers and is driven by a large gear system. The lining protects the steel shell from the extreme internal temperatures and any corrosive materials.

The length, diameter, rotation speed, and incline angle are all carefully calculated to control how long the material spends inside the kiln, a critical parameter known as "residence time."

The Heating and Discharge System

The heat source is typically located at the discharge end, creating a counter-current flow where the hottest gases meet the most processed material.

Once the material reaches the lower end of the kiln, it exits through a discharge housing. It may then enter an air-cooling mechanism to bring its temperature down in a controlled manner, stabilizing the final product.

Understanding the Trade-offs and Design Considerations

While powerful, the effective operation of a rotary kiln depends on precise engineering and maintenance. Several factors are critical to its performance and longevity.

Preventing Material Contamination

For high-purity applications, the kiln can be customized to suppress metal contamination from its internal components. This is crucial in industries like specialty chemicals or advanced ceramics.

Ensuring Airtightness and Safety

Proper sealing at both the feed and discharge ends is essential. These seals prevent the leakage of hot gas or dust, ensure process airtightness for atmospheric control, and stop raw material from scattering.

The Critical Role of Alignment

The construction, position, and alignment of the kiln are paramount for smooth, long-term operation. Even a minor misalignment of the massive rotating cylinder can create immense mechanical stress, leading to premature wear on the support rollers, tires, and drive system.

Aligning Kiln Design with Your Processing Goal

The optimal rotary kiln setup depends entirely on the specific material and the desired transformation. The principles remain the same, but the configuration must be tailored to the goal.

- If your primary focus is a chemical reaction (like calcination): Your priority is precise control over temperature and residence time to ensure the reaction fully completes, as seen when making cement from limestone.

- If your primary focus is drying or moisture removal: You need efficient airflow to carry away vapor, working in concert with a heat profile that removes moisture without damaging the material.

- If your primary focus is coating a product (like heat setting): The key is uniform heat application and gentle tumbling to create an even, securely bonded coat without breaking down the core material.

- If your primary focus is waste incineration: The design must prioritize complete organic combustion, extreme temperature endurance, and robust off-gas treatment systems to meet environmental standards.

Ultimately, the rotary kiln’s genius lies in its simple, adaptable mechanics, making it an indispensable cornerstone of modern thermal processing.

Summary Table:

| Principle | Function | Benefit |

|---|---|---|

| Gravity & Incline | Moves material through the cylinder | Continuous, automated processing |

| Mechanical Rotation | Tumbles and mixes the material bed | Uniform heating and consistent product quality |

| High-Temperature Heat Transfer | Drives physical/chemical changes | Efficient drying, calcination, or reaction |

| Controlled Residence Time | Manages duration material spends in kiln | Precise process control for specific outcomes |

Ready to optimize your thermal processing?

KINTEK's rotary kilns are engineered for precision and durability, delivering the uniform heating and reliable performance your laboratory or production facility demands. Whether your goal is calcination, drying, coating, or incineration, our expertise in lab equipment ensures a solution tailored to your specific material and process requirements.

Contact us today to discuss how a KINTEK rotary kiln can enhance your efficiency and product quality.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

People Also Ask

- What are disadvantages of pyrolysis process? Key Challenges in Energy, Cost, and Product Stability

- What is the activation temperature of activated carbon? A Guide to Method, Temperature, and Pore Structure

- What is the purpose of a fluidized bed? Achieve Superior Heat Transfer and Process Efficiency

- What furnace is used for calcination? A Guide to Muffle, Rotary Kiln, and Shaft Furnaces

- What is the residence time of microwave pyrolysis? Achieve Fast, Efficient Biomass Conversion

- What is calcination in short answer? A Guide to High-Temperature Material Transformation

- What is the temperature range of a rotary kiln? A Guide to Custom Thermal Profiles

- Where are rotary kilns used? The Heart of Industrial Processing for Cement, Metals & More