At its core, oil sludge is the precursor to catastrophic engine failure. It is a thick, tar-like gel that forms inside an engine when motor oil breaks down and becomes contaminated. Unlike liquid oil, sludge cannot properly circulate or lubricate, effectively blocking the engine's "arteries" and starving critical components of the oil they need to survive.

The central problem with oil sludge is not that it's "dirty oil," but that it is a semi-solid blockage. It restricts or completely stops oil flow, leading to rapid component wear, overheating, and ultimately, irreversible engine seizure.

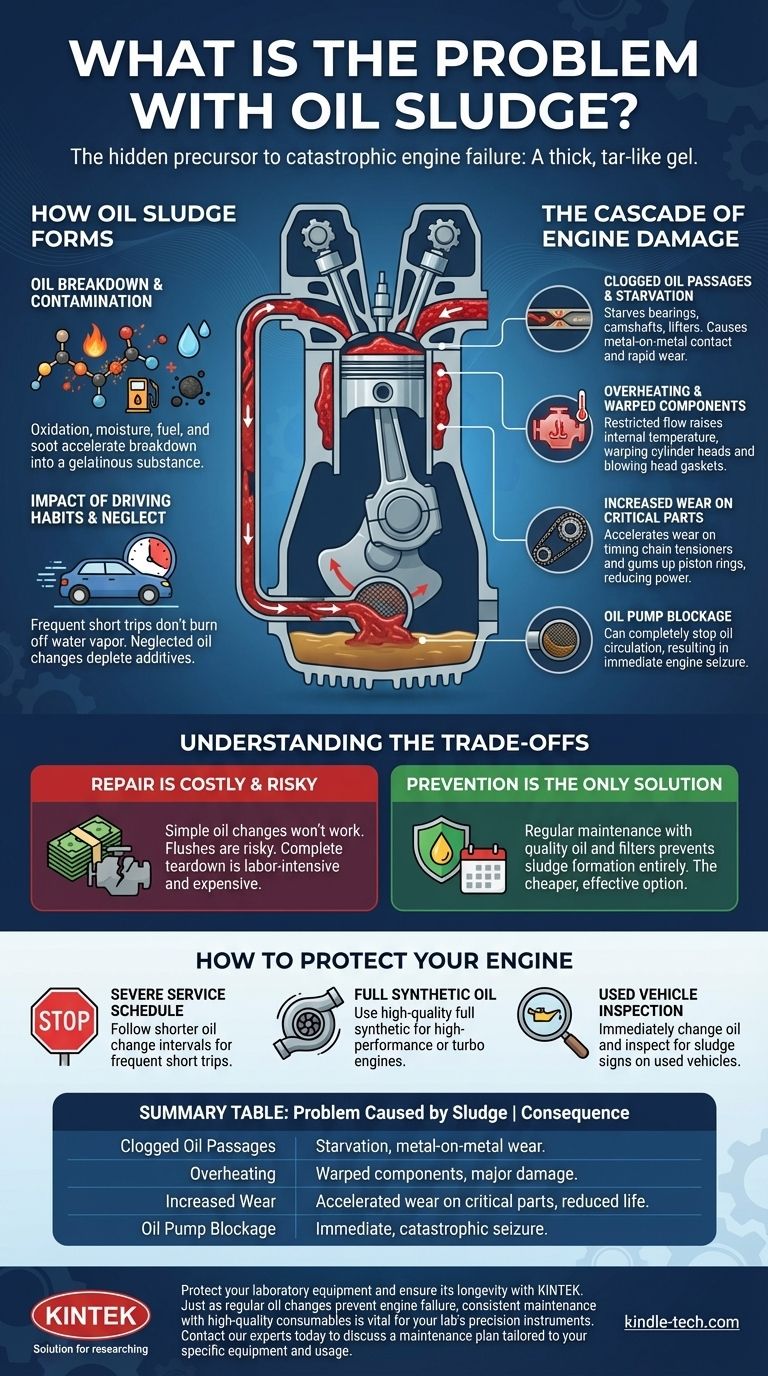

How Oil Sludge Forms

Understanding how sludge forms is the first step in preventing it. It is not a single event, but a process of degradation accelerated by specific conditions.

The Role of Oil Breakdown and Contamination

Motor oil is designed to withstand extreme heat, but it has a finite lifespan. Over time, high temperatures cause the oil to oxidize, a process that breaks down its molecular structure and reduces its ability to lubricate.

Contaminants dramatically accelerate this breakdown. Moisture from condensation, unburnt fuel, and soot from combustion all mix with the degrading oil, creating the thick, gelatinous substance we call sludge.

The Impact of Driving Habits

Your driving style is a major factor. Frequent short trips are a primary cause of sludge, especially in colder climates.

On short drives, the engine never reaches its optimal operating temperature for long enough to burn off the water vapor that accumulates in the crankcase. This moisture then churns with the oil, creating a sludge-prone emulsion, much like mixing oil and vinegar.

Neglected Maintenance as the Primary Culprit

The single greatest contributor to sludge formation is failing to change the oil at recommended intervals.

Fresh motor oil contains a precise package of additives, including detergents to clean internal surfaces and dispersants to hold contaminants in suspension so they can be removed by the oil filter. As the oil ages, these additives are depleted, allowing contaminants to clump together and form sludge.

The Cascade of Engine Damage Caused by Sludge

Once sludge begins to form, it initiates a chain reaction of failures that grow progressively worse and more expensive.

Clogged Oil Passages and Starvation

This is the most immediate and dangerous effect. Sludge is too thick to flow through the engine's narrow oil passages.

Key components like the oil pump pickup screen can become completely blocked, preventing any oil from circulating. This starves parts like bearings, camshafts, and lifters, causing metal-on-metal contact and rapid, destructive wear.

Overheating and Warped Components

Motor oil is responsible for a significant portion of an engine's cooling. By restricting oil flow, sludge causes internal temperatures to skyrocket.

This localized overheating can lead to warped cylinder heads, blown head gaskets, and other major failures that often require a complete engine rebuild to correct.

Increased Wear on Critical Components

Even in smaller amounts, sludge accelerates wear on the entire engine. It can block the small orifices that supply oil to timing chain tensioners, causing the chain to fail and leading to catastrophic valve and piston damage.

It also gums up piston rings, causing them to stick. This results in a loss of compression, reduced power, poor fuel economy, and a sharp increase in oil consumption.

Understanding the Trade-offs: Repair vs. Prevention

Addressing a sludge problem is fundamentally different from preventing one. The options for repair are limited, costly, and carry significant risk.

The High Cost and Uncertainty of Sludge Removal

Once an engine is filled with sludge, a simple oil change is useless. The damage has often already begun, and the sludge itself is too thick to drain out.

So-called "engine flushes" can be risky, as they can dislodge a large chunk of sludge that then travels and blocks a critical oil passage, causing immediate engine seizure. The only certain way to remove severe sludge is a complete engine teardown and manual cleaning, a process that is extremely labor-intensive and can easily cost thousands of dollars.

Why Prevention Is the Only Real Solution

The cost of an oil change is microscopic compared to the cost of an engine rebuild or replacement. Prevention is not just the cheaper option; it is the only effective one.

By performing regular maintenance with quality oil and filters, you ensure the additive package is always strong enough to prevent the oxidation and contamination process from ever creating sludge in the first place.

How to Protect Your Engine from Oil Sludge

Your strategy for prevention should be tailored to your vehicle and how you use it.

- If you primarily drive short distances or in stop-and-go traffic: You must follow the "severe service" maintenance schedule in your vehicle's owner's manual, which often recommends oil changes at shorter intervals (e.g., every 3,000-5,000 miles).

- If you own a turbocharged or high-performance engine: Use a high-quality full synthetic oil, as these engines generate more heat and put greater stress on the oil. Sticking to a strict change interval is non-negotiable.

- If you've purchased a used vehicle with an unknown service history: The safest course of action is to perform an immediate oil change and have a trusted mechanic inspect for signs of sludge by looking into the oil filler cap and under the valve cover, if possible.

Ultimately, consistent maintenance with the correct oil is the single most effective defense against sludge, ensuring your engine's long-term health and reliability.

Summary Table:

| Problem Caused by Sludge | Consequence |

|---|---|

| Clogged Oil Passages | Starves critical components of oil, leading to metal-on-metal wear and failure. |

| Overheating | Causes warped components, blown head gaskets, and major engine damage. |

| Increased Wear | Accelerates wear on piston rings, timing chains, and bearings, reducing engine life. |

| Oil Pump Blockage | Can completely stop oil circulation, resulting in immediate and catastrophic engine seizure. |

Protect your laboratory equipment and ensure its longevity with KINTEK. Just as regular oil changes prevent engine failure, consistent maintenance with high-quality consumables is vital for your lab's precision instruments. KINTEK specializes in lab equipment and consumables, serving all your laboratory needs to prevent downtime and ensure reliable performance. Contact our experts today to discuss a maintenance plan tailored to your specific equipment and usage.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Bottle Oil Fume Sampling Tube

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What are the disadvantages of oil sludge? Avoid Catastrophic Engine Damage and Costly Repairs

- What is the lifespan of a filter media? Understand the 3 Types for Optimal Filtration

- Why is slender PTFE tubing necessary for flow control in multi-channel catalyst aging? Ensure Equal Gas Distribution

- What are the problems for bio oils utilization? Overcome Key Barriers to Renewable Fuel Adoption

- Is PTFE corrosion resistant? Discover the Ultimate Chemical Resistance for Your Lab