At its core, continuous sintering is a high-volume manufacturing process that transforms powdered materials into a solid, dense mass by moving them through a long furnace with controlled temperature zones. Unlike batch processes where materials are loaded, heated, and cooled in a static chamber, continuous sintering uses a conveyor system to ensure a constant, automated flow of parts, dramatically increasing production speed and consistency.

The critical distinction to understand is that continuous sintering prioritizes throughput and scalability over the precise atmospheric control offered by batch processes. This makes it the ideal method for mass production of metal and ceramic components where efficiency is paramount.

The Fundamental Goal: From Powder to Solid

To understand continuous sintering, we must first grasp the core principles of the sintering process itself. It's a method of consolidation driven by thermal energy.

What is Sintering?

Sintering is the process of compacting and forming a solid mass from a powdered material by applying heat and pressure. Crucially, the temperature is kept below the material's melting point.

The goal is to reduce the porous spaces between the initial particles, forcing them to bond and create a dense, solid object.

The Atomic-Level Mechanism

The magic of sintering happens at the atomic level. As the material is heated, atoms gain energy and diffuse across the boundaries of adjacent particles.

This atomic migration effectively "welds" the particles together, fusing them into a single, cohesive piece with significantly greater strength and density.

Why Not Simply Melt?

Sintering is essential for materials with extremely high melting points, such as tungsten and molybdenum, where melting would be impractical and energy-intensive.

Furthermore, it allows for the creation of parts with controlled porosity or specific microstructures that would be impossible to achieve through casting.

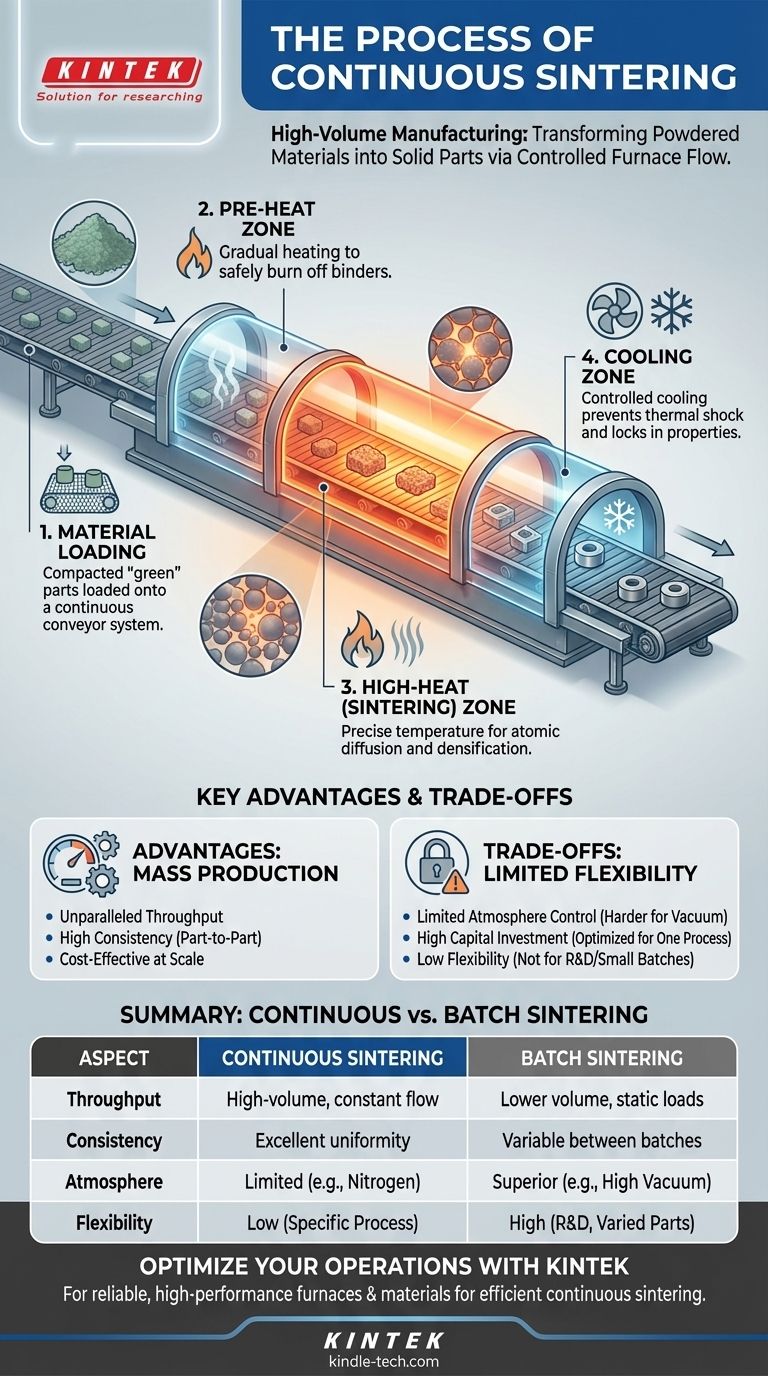

The Continuous Sintering Process: A Step-by-Step Flow

The continuous process converts the principles of sintering into an efficient, assembly-line-style operation. The parts, often referred to as "green" compacts, move sequentially through different zones of a tunnel furnace.

Step 1: Material Loading

Compacted "green" parts are loaded onto a mesh belt conveyor or pushed by a ceramic pusher mechanism at the entrance of the furnace. The loading rate is carefully controlled to match the furnace's processing speed.

Step 2: The Pre-Heat Zone

As parts enter the furnace, they first pass through a pre-heat or binder burnout zone. The temperature is gradually increased to safely burn off any lubricants or binding agents used in the initial powder compaction stage.

Step 3: The High-Heat (Sintering) Zone

Next, the parts move into the hottest section of the furnace, where the temperature is held at the precise sintering point for that specific material. It is in this zone that the critical atomic diffusion and densification occur.

Step 4: The Cooling Zone

Finally, the newly sintered parts travel through a controlled cooling section. This gradual reduction in temperature is vital to prevent thermal shock, which could cause cracking, and to lock in the desired final material properties.

Understanding the Trade-offs: Continuous vs. Batch Sintering

The choice between continuous and batch sintering (like vacuum or microwave sintering) is a strategic one, defined by a clear set of trade-offs.

Advantage: Throughput and Scalability

The primary benefit of continuous sintering is its immense throughput. It is designed for non-stop, high-volume production, making it incredibly cost-effective at scale.

Advantage: Consistency

Because every part follows the exact same path and experiences the identical thermal profile, part-to-part consistency is exceptionally high. This is crucial for applications with tight quality control requirements.

Limitation: Atmospheric Control

While a controlled atmosphere (like nitrogen or hydrogen) can be maintained, it is much harder to achieve a high-purity vacuum compared to a sealed batch furnace. This makes continuous sintering less suitable for highly reactive materials that require pristine environments.

Limitation: Flexibility

Continuous furnaces are large, capital-intensive pieces of equipment optimized for one specific process. They are not easily adjusted, making them inefficient for research, prototyping, or small production runs of varied parts.

Making the Right Choice for Your Goal

The choice between a continuous or batch sintering process depends entirely on your operational priorities and material requirements.

- If your primary focus is high-volume production and cost-efficiency: Continuous sintering is the clear choice for its unparalleled speed, automation, and consistency in mass manufacturing.

- If your primary focus is material purity and precise properties: Batch processes, such as vacuum sintering, offer superior control over the atmosphere, which is critical for reactive metals or advanced ceramics.

- If your primary focus is R&D or producing diverse, small-batch parts: The flexibility of a batch furnace is essential for testing different thermal cycles and accommodating various material compositions without major downtime.

By understanding this fundamental process distinction, you can confidently align your manufacturing strategy with your specific material and business objectives.

Summary Table:

| Aspect | Continuous Sintering | Batch Sintering |

|---|---|---|

| Throughput | High-volume, constant flow | Lower volume, static loads |

| Consistency | Excellent part-to-part uniformity | Variable between batches |

| Atmosphere Control | Limited (e.g., nitrogen/hydrogen) | Superior (e.g., high vacuum) |

| Flexibility | Low (optimized for one process) | High (ideal for R&D and varied parts) |

| Best For | Mass production of standard components | Reactive materials, prototyping, small batches |

Ready to scale up your component production with reliable sintering solutions? KINTEK specializes in lab equipment and consumables, providing the durable, high-performance furnaces and materials needed for efficient continuous sintering processes. Whether you're mass-producing metal or ceramic parts, our expertise ensures you achieve the consistency and throughput your laboratory demands. Contact us today to discuss how KINTEK can optimize your sintering operations!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What are the benefits of vacuum drying? Achieve Gentle, Efficient Drying for Sensitive Materials

- What is the purpose of quenching aluminum? To Lock in Strength for Age Hardening

- What is the function of a vacuum arc melting furnace? Master Homogeneity for Fe-Co Metallic Glasses

- How does a vacuum furnace facilitate the synthesis of Mg3Sb2? Achieving High-Purity Zintl Phase Materials

- Why is the diffusion bonding process within a vacuum furnace critical for near-alpha titanium alloy materials?

- How does the degassing step in a vacuum oven influence the quality of molded F-LSR components? Enhance Material Strength

- How does a high-temperature steam oxidation test system assist in safety verification of molybdenum alloy cladding?

- What is the principle of vacuum furnace? Achieve Purity and Precision in Material Processing