At its core, furnace soldering is a high-volume process for joining multiple components simultaneously using a precisely controlled heating and cooling cycle within a regulated atmosphere. It differs significantly from sintering, a process described in the references which fuses powders into a solid mass. Furnace soldering uses a filler metal (solder) to create strong, clean joints across entire assemblies without the need for manual, point-by-point application.

The fundamental advantage of furnace soldering is not just heating, but achieving a perfect joint by controlling the entire thermal and atmospheric environment. This prevents oxidation and ensures the solder flows precisely where needed, making it a cornerstone of high-reliability manufacturing.

The Fundamental Difference: Soldering vs. Sintering

Before detailing the soldering process, it is critical to distinguish it from sintering, a common point of confusion as they both use high-temperature furnaces.

What is Soldering?

Soldering is a joining process where two or more metal items are joined together by melting and flowing a filler metal (solder) into the joint. The base materials themselves are not melted; only the solder is.

What is Sintering?

Sintering is a process that uses heat and sometimes pressure to fuse particles of a powder together into a solid, coherent mass. The material is heated below its melting point until the individual particles bond, creating a single solid piece.

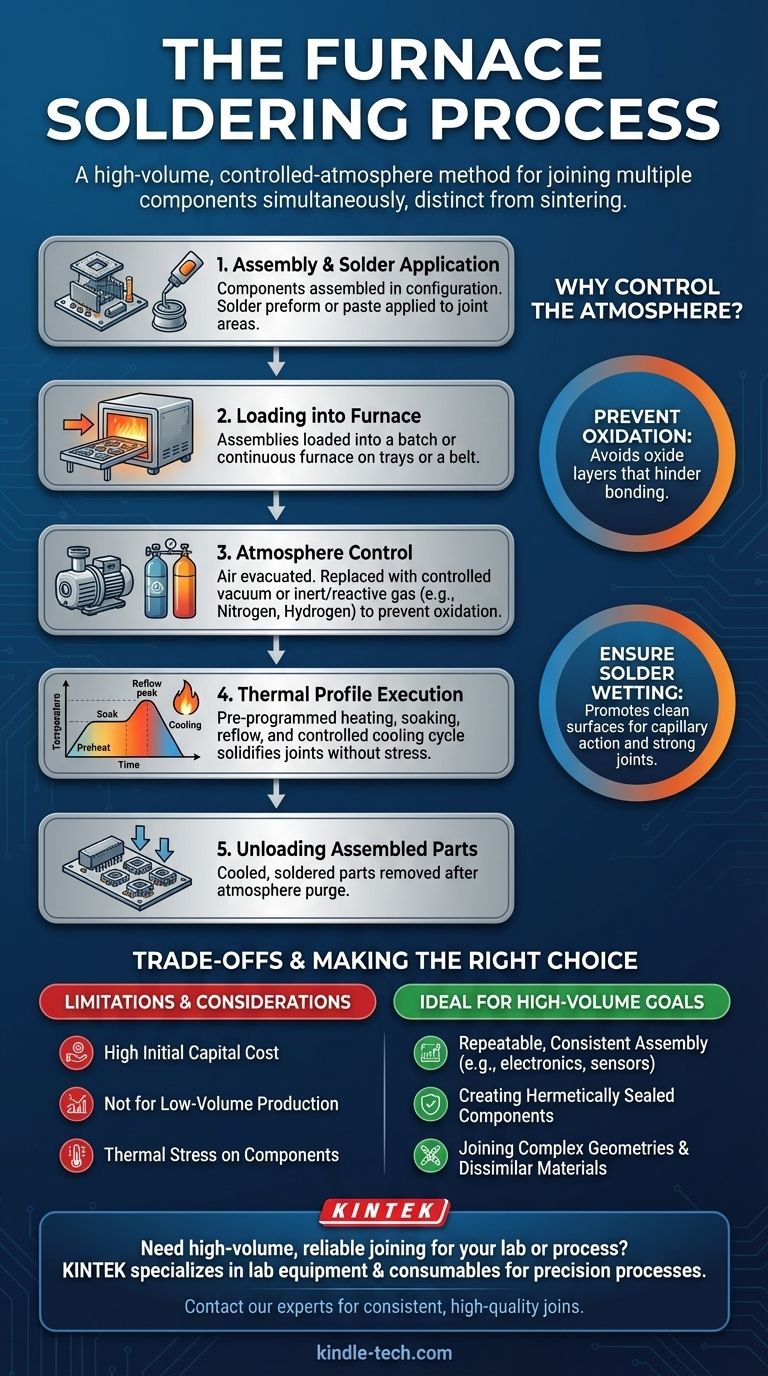

The Step-by-Step Furnace Soldering Process

The furnace soldering process is a carefully choreographed sequence designed for repeatability and quality control.

Step 1: Component Assembly and Solder Application

First, the components to be joined are assembled in their final configuration. Solder is applied to the joint areas, typically as a pre-shaped solder preform (a stamped shape of solder alloy) or as a solder paste (a mix of solder powder and flux).

Step 2: Loading into the Furnace

The assemblies are loaded onto trays or a conveyor belt and placed inside the furnace. This can be a batch furnace, where a single load is processed at once, or a continuous furnace, where a belt carries assemblies through different temperature zones.

Step 3: Atmosphere Control

The furnace is sealed, and the air is removed. It is replaced with a tightly controlled atmosphere, which is crucial for success. This is often a vacuum or, more commonly, an inert gas like nitrogen or a reactive gas mix like hydrogen.

Step 4: The Thermal Profile

The furnace executes a pre-programmed thermal profile. This involves ramping up the temperature at a specific rate, holding it at a "soak" temperature to allow the assembly to stabilize, rising again to the peak reflow temperature to melt the solder, and finally, a controlled cool-down to solidify the joints without thermal shock.

Step 5: Unloading the Assembled Parts

Once the cycle is complete and the assemblies have cooled, the controlled atmosphere is purged, and the finished, soldered parts are removed from the furnace.

Why Control the Atmosphere? The Core Principle

The use of a vacuum or specific gas atmosphere, similar to the sintering processes mentioned in the references, is the most critical aspect of furnace soldering.

Preventing Oxidation

At high temperatures, metals react rapidly with oxygen, forming oxides on the surface. These oxide layers prevent the solder from properly bonding to the base metal, leading to weak or failed joints. An inert atmosphere eliminates this risk.

Ensuring Proper Solder Wetting

"Wetting" is the ability of liquid solder to flow over and adhere to a solid surface. A clean, oxide-free surface, maintained by the controlled atmosphere, promotes excellent wetting, allowing solder to be drawn into the joint by capillary action for a strong, complete connection.

Understanding the Trade-offs

While powerful, furnace soldering is not a universal solution. Understanding its limitations is key to making an informed decision.

High Initial Capital Cost

Furnaces, especially those with advanced atmospheric controls, represent a significant capital investment compared to hand-soldering stations or small-scale reflow ovens.

Not Suitable for Low-Volume Production

The setup, programming of thermal profiles, and cycle time make furnace soldering inefficient for one-off prototypes or very small production runs. Its strength lies in medium to high-volume manufacturing where consistency is paramount.

Thermal Stress Considerations

Subjecting an entire assembly to high temperatures can introduce thermal stress. Components must be selected to have compatible coefficients of thermal expansion to avoid damage or warping during the heating and cooling cycle.

Making the Right Choice for Your Goal

Furnace soldering is a specialized process best suited for specific manufacturing challenges.

- If your primary focus is high-volume, repeatable assembly: Furnace soldering provides unparalleled consistency for producing thousands of identical, high-quality assemblies, such as in electronics or automotive sensor manufacturing.

- If your primary focus is creating hermetically sealed components: The clean, flux-free joints created in a controlled atmosphere are ideal for sealing electronic packages, sensors, and aerospace components against the environment.

- If your primary focus is joining complex geometries or dissimilar materials: Furnace soldering can simultaneously create multiple joints on complex parts where hand soldering would be impractical or impossible.

Understanding this process allows you to select the right joining technology based on your specific requirements for quality, volume, and performance.

Summary Table:

| Process Step | Key Action | Purpose |

|---|---|---|

| 1. Assembly & Solder Application | Components assembled; solder preform or paste applied. | Prepares joint for bonding. |

| 2. Loading | Assemblies placed in batch or continuous furnace. | Prepares for controlled heating cycle. |

| 3. Atmosphere Control | Air removed; replaced with vacuum or inert/reactive gas. | Prevents oxidation for proper solder wetting. |

| 4. Thermal Profile | Pre-programmed heating, soaking, reflow, and cooling. | Melts solder uniformly and solidifies joints without stress. |

| 5. Unloading | Finished, soldered parts are removed after cooling. | Completes the high-reliability joining process. |

Need high-volume, reliable joining for your laboratory or manufacturing process?

Furnace soldering is ideal for creating strong, hermetically sealed assemblies in electronics, aerospace, and sensor manufacturing. At KINTEK, we specialize in the lab equipment and consumables that make precision processes like this possible.

Let us help you achieve flawless results: We provide the expertise and solutions for consistent, high-quality joins. Contact our experts today via our form to discuss how we can support your production goals with the right equipment and materials.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond