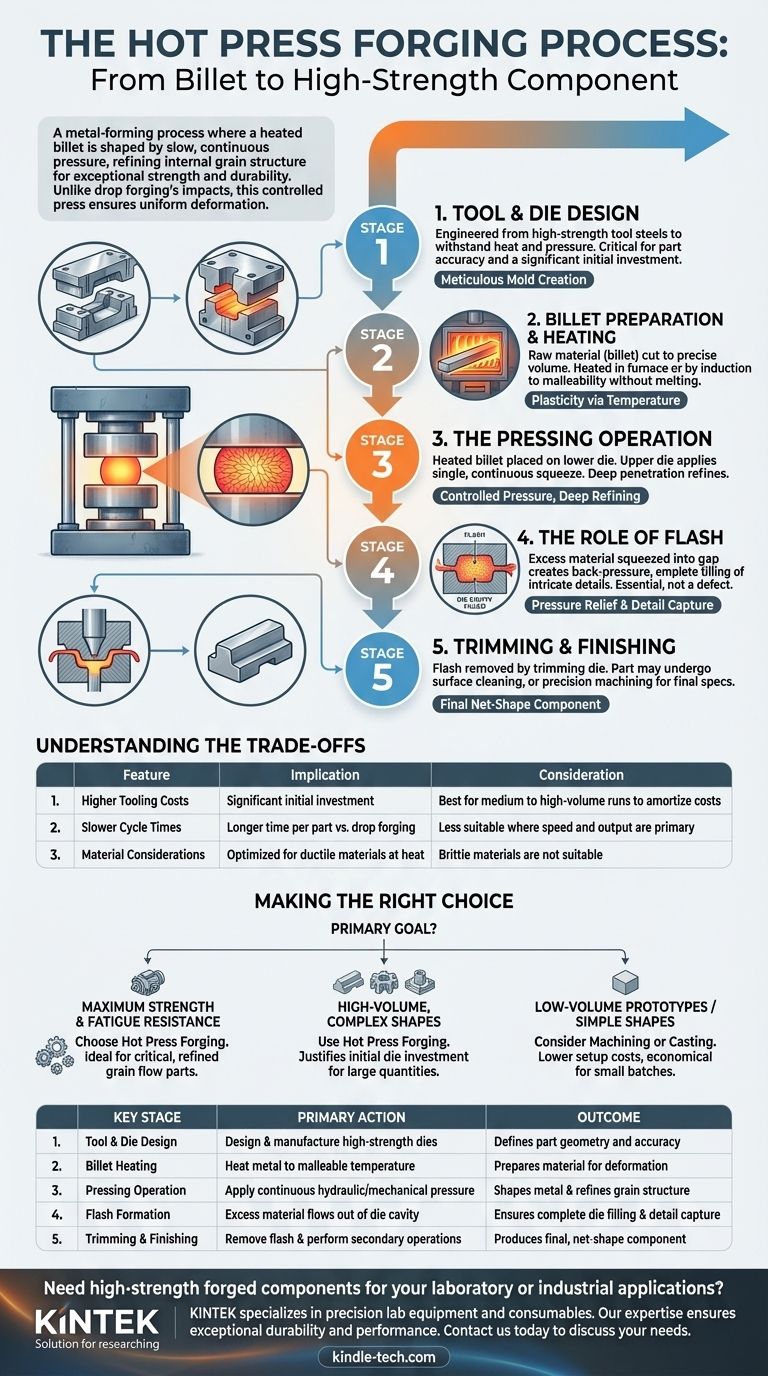

At its core, hot press forging is a metal-forming process where a piece of metal, known as a billet, is heated to a malleable temperature below its melting point. This heated billet is then placed between two dies and shaped by applying slow, continuous, and immense mechanical or hydraulic pressure. Unlike the violent impacts of drop forging, this controlled pressing action squeezes the metal, forcing it to fill the die cavity and conform to the desired shape.

The true value of hot press forging is not just in creating a shape, but in refining the metal's internal grain structure. This process produces components with exceptional strength, density, and fatigue resistance that are often superior to parts made by casting or machining.

The Hot Press Forging Process: A Step-by-Step Breakdown

Understanding the journey from a simple metal bar to a high-strength component reveals why this process is chosen for critical applications.

Step 1: Tool and Die Design

The entire process begins with engineering. Dies, which act as the molds for the metal, are meticulously designed and manufactured based on the final component's specifications.

These tools are typically made from high-strength, wear-resistant tool steels, as they must withstand extreme temperatures and pressures repeatedly. This initial tooling phase is a significant investment and is critical to the part's final accuracy.

Step 2: Billet Preparation and Heating

Raw material, usually in the form of a bar or ingot called a billet, is cut to a precise volume. The volume must be exact enough to fill the die cavity with a small, planned amount of excess.

The billet is then heated in a furnace or via induction to its forging temperature. This temperature, which varies by alloy, makes the metal plastic and malleable without melting it, allowing it to be shaped with less force and without cracking.

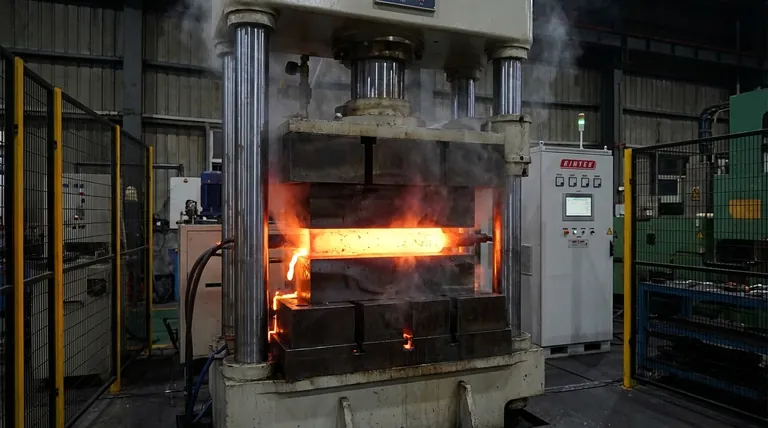

Step 3: The Pressing Operation

The heated billet is quickly transferred to the press and placed on the lower die. The press then forces the upper die down onto the billet with a single, continuous squeezing motion.

This slow application of pressure is a key characteristic of press forging. It ensures the deformation penetrates deep into the center of the workpiece, refining the grain structure uniformly throughout the part.

Step 4: The Role of Flash

As the dies close, some excess material is squeezed out of the die cavity into a small gap. This excess material is called flash.

Flash is not a defect; it is a planned and essential part of the process. It acts as a pressure relief valve and, more importantly, its resistance to flow creates back-pressure that ensures the main die cavity is completely filled, capturing every intricate detail of the design.

Step 5: Trimming and Finishing

After the part is formed, it is removed from the press, and the flash is cut off in a secondary operation, often using a dedicated trimming die.

The forged component may then undergo further processes like heat treatment to achieve specific mechanical properties, shot blasting to clean the surface, or precision machining for features that require extremely tight tolerances.

Understanding the Trade-offs and Limitations

While powerful, hot press forging is not the right solution for every problem. Objectively weighing its trade-offs is crucial for making an informed decision.

Higher Initial Tooling Costs

The design and fabrication of robust, heat-resistant dies represent a significant upfront cost. As the reference material notes, these dies are more complex and expensive than molds used for casting.

This investment makes press forging best suited for medium to high-volume production runs where the cost can be amortized across thousands of units.

Slower Cycle Times

Compared to the rapid blows of drop forging, the slow, controlled squeeze of a forging press results in a longer cycle time per part.

This makes the process less suitable for applications where sheer speed and maximum output are the primary drivers over part quality and complexity.

Material Considerations

While a wide range of ferrous and non-ferrous metals can be press forged (including steel, aluminum, and titanium alloys), the process is optimized for materials with good ductility at elevated temperatures. Brittle materials are not suitable candidates.

Making the Right Choice for Your Component

To determine if hot press forging is the correct manufacturing path, align the process capabilities with your primary engineering goal.

- If your primary focus is maximum strength and fatigue resistance: Choose hot press forging for its ability to produce a refined and continuous grain flow, ideal for critical parts like engine components, gears, and structural fittings.

- If your primary focus is high-volume production of complex shapes: Use hot press forging when the part geometry is intricate and the production volume is large enough to justify the initial die investment.

- If your primary focus is low-volume prototypes or simple shapes: Consider alternative methods like machining from bar stock or casting, which have lower initial setup costs and are more economical for small quantities.

Ultimately, hot press forging is an engineering tool for creating components where strength and reliability are non-negotiable.

Summary Table:

| Key Stage | Primary Action | Outcome |

|---|---|---|

| Tool & Die Design | Design and manufacture high-strength dies | Defines part geometry and accuracy |

| Billet Heating | Heat metal to a malleable temperature | Prepares material for deformation |

| Pressing Operation | Apply continuous hydraulic/mechanical pressure | Shapes metal and refines grain structure |

| Flash Formation | Excess material flows out of die cavity | Ensures complete die filling and detail capture |

| Trimming & Finishing | Remove flash and perform secondary operations | Produces final, net-shape component |

Need high-strength forged components for your laboratory or industrial applications? KINTEK specializes in precision lab equipment and consumables, and we understand the critical role of reliable metal parts in demanding environments. Our expertise in materials and manufacturing processes ensures you get components with exceptional durability and performance. Contact us today to discuss how our solutions can meet your specific needs for strength and reliability.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production

- Why is a vacuum essential for sintering metal-ceramic composites? Achieve Pure, High-Density Results

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification