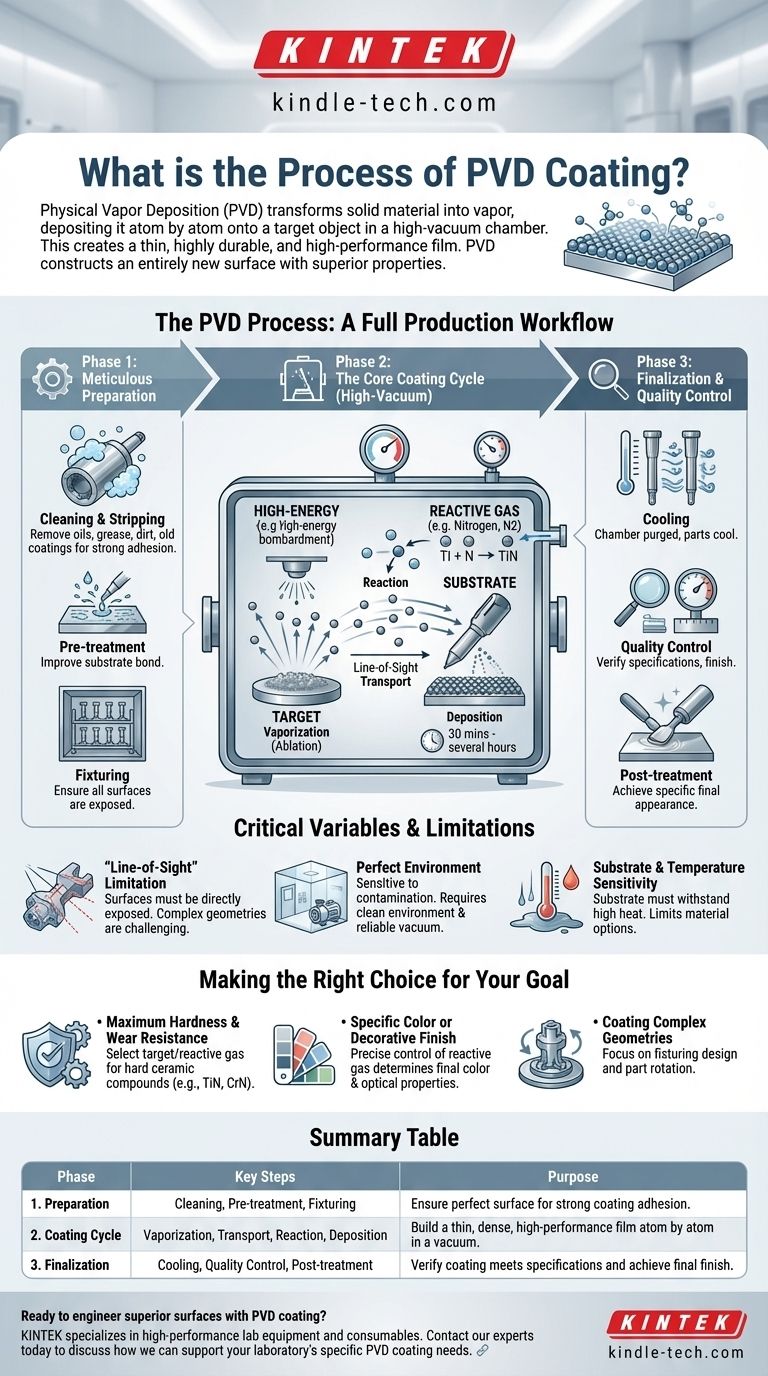

At its core, Physical Vapor Deposition (PVD) is a vacuum coating process that transforms a solid material into a vapor, which is then deposited atom by atom onto a target object. This creates a thin, highly durable, and high-performance film. The entire process takes place within a high-vacuum chamber to ensure the purity and quality of the final coating.

PVD should be understood not as a simple coating application, but as the construction of an entirely new surface. It is a highly controlled, atomic-level process designed to build a thin film with properties often superior to the underlying material itself.

The PVD Process: A Full Production Workflow

Viewing the PVD process simply as the moment of deposition is a common mistake. In practice, it is a multi-stage workflow where each step is critical to achieving a high-quality, well-adhered coating.

Phase 1: Meticulous Preparation

Before a part ever enters the PVD chamber, it must be perfectly prepared. Any failure in this phase will almost certainly lead to a failure of the coating itself.

The first step is cleaning and stripping. The substrate (the part to be coated) must be absolutely free of oils, grease, dirt, or any previous coatings. This is a foundational step for ensuring strong adhesion.

Next is pre-treatment. Depending on the substrate material, this may involve chemical etching or other surface modifications designed to improve the bond between the substrate and the PVD coating.

Finally, parts are placed on specialized fixtures or racks. This fixturing is crucial for ensuring all necessary surfaces are exposed to the coating vapor during the process.

Phase 2: The Core Coating Cycle

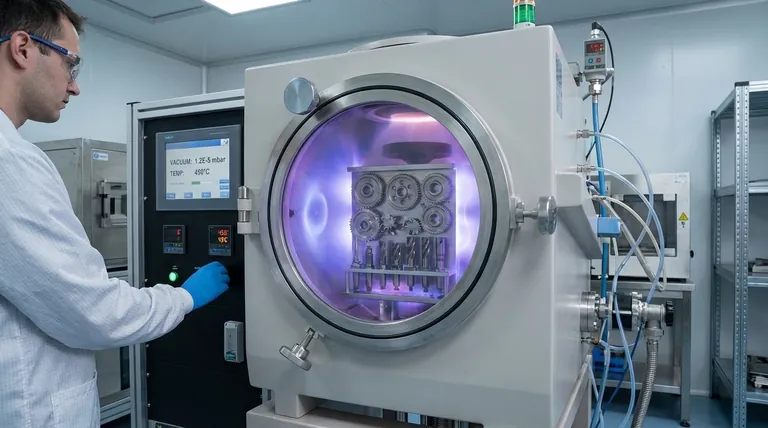

This is the heart of the PVD process, occurring entirely within a sealed, high-vacuum chamber. The vacuum is essential because it removes atmospheric particles that could react with or contaminate the coating.

The cycle consists of four distinct physical stages:

-

Vaporization (Ablation): A solid source material, known as a target, is converted into a vapor. Common target materials include titanium, zirconium, or chromium. This is typically achieved through high-energy bombardment, using methods like sputtering (with ions) or cathodic arc discharge.

-

Transport: The vaporized atoms travel from the target towards the substrate within the vacuum chamber. This journey is typically in a "line-of-sight" path.

-

Reaction: For many applications, a specific reactive gas (such as nitrogen or a carbon-containing gas) is precisely introduced into the chamber. The vaporized metal atoms react with this gas mid-flight to form a new compound, which determines the coating's final properties like hardness and color. For example, titanium reacts with nitrogen to form Titanium Nitride (TiN).

-

Deposition: The metal or metal-compound vapor reaches the substrate and condenses, forming a thin, dense, and strongly bonded film. This deposition happens atom by atom, building the layer with exceptional uniformity and purity. The entire in-chamber process can take anywhere from 30 minutes to several hours.

Phase 3: Finalization and Quality Control

Once the deposition is complete, the parts are allowed to cool. The chamber is purged with an inert gas to remove any residual reactive vapors before being brought back to atmospheric pressure.

A final quality control check is performed. This includes visual inspection to ensure every surface is finished correctly and, often, thickness measurements to verify the coating meets precise specifications.

Some applications may also require post-treatment, such as polishing, to achieve a specific final appearance or texture.

Understanding the Critical Variables and Limitations

While powerful, the PVD process is not without its operational challenges and inherent trade-offs. Understanding these is key to its successful application.

The "Line-of-Sight" Limitation

Because the vaporized material travels in a straight line, PVD is a line-of-sight process. Surfaces that are not directly exposed to the target source will not be coated effectively. This makes coating complex internal geometries challenging and requires sophisticated part rotation and fixturing to ensure uniform coverage.

The Necessity of a Perfect Environment

The process is extremely sensitive to contamination. A microscopic particle of dust or a minor vacuum leak can compromise the integrity of an entire batch. This demands a meticulously clean production environment and highly reliable vacuum equipment.

Substrate and Temperature Sensitivity

The PVD process generates significant heat inside the chamber. The substrate material must be able to withstand these temperatures without deforming, melting, or having its own properties negatively altered. This limits the types of materials that can be effectively coated.

Making the Right Choice for Your Goal

Selecting the right PVD parameters is about matching the process to the desired outcome.

- If your primary focus is maximum hardness and wear resistance: The key is the selection of the target material and reactive gas to create hard ceramic compounds like Titanium Nitride (TiN) or Chromium Nitride (CrN).

- If your primary focus is a specific color or decorative finish: The precise control of the reactive gas mixture is the most critical variable, as it directly determines the final color and optical properties of the film.

- If your primary focus is coating complex geometries: The design of the fixturing and the part's rotation and movement within the chamber are more important than any other single factor.

Ultimately, understanding the PVD process is the first step toward leveraging its power to engineer superior surfaces.

Summary Table:

| Phase | Key Steps | Purpose |

|---|---|---|

| 1. Preparation | Cleaning, Pre-treatment, Fixturing | Ensure perfect surface for strong coating adhesion |

| 2. Coating Cycle | Vaporization, Transport, Reaction, Deposition | Build a thin, dense, high-performance film atom by atom in a vacuum |

| 3. Finalization | Cooling, Quality Control, Post-treatment | Verify coating meets specifications and achieve final finish |

Ready to engineer superior surfaces with PVD coating?

KINTEK specializes in high-performance lab equipment and consumables, including solutions for advanced coating processes. Whether you need to enhance wear resistance, achieve specific decorative finishes, or coat complex geometries, our expertise can help you achieve your goals.

Contact our experts today to discuss how we can support your laboratory's specific PVD coating needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing