Vacuum Induction Melting (VIM) is a highly controlled process for producing exceptionally clean, high-purity metals and alloys. Often called "VIM metal," the material is melted inside a sealed chamber under a deep vacuum using electromagnetic induction. This environment prevents contamination from the atmosphere and allows for precise control over the final chemistry, resulting in materials with superior mechanical properties.

The core purpose of VIM is not just to melt metal, but to refine it. By removing the reactive gases found in air, the process eliminates impurities that compromise material strength and performance, enabling the creation of advanced alloys impossible to produce by conventional means.

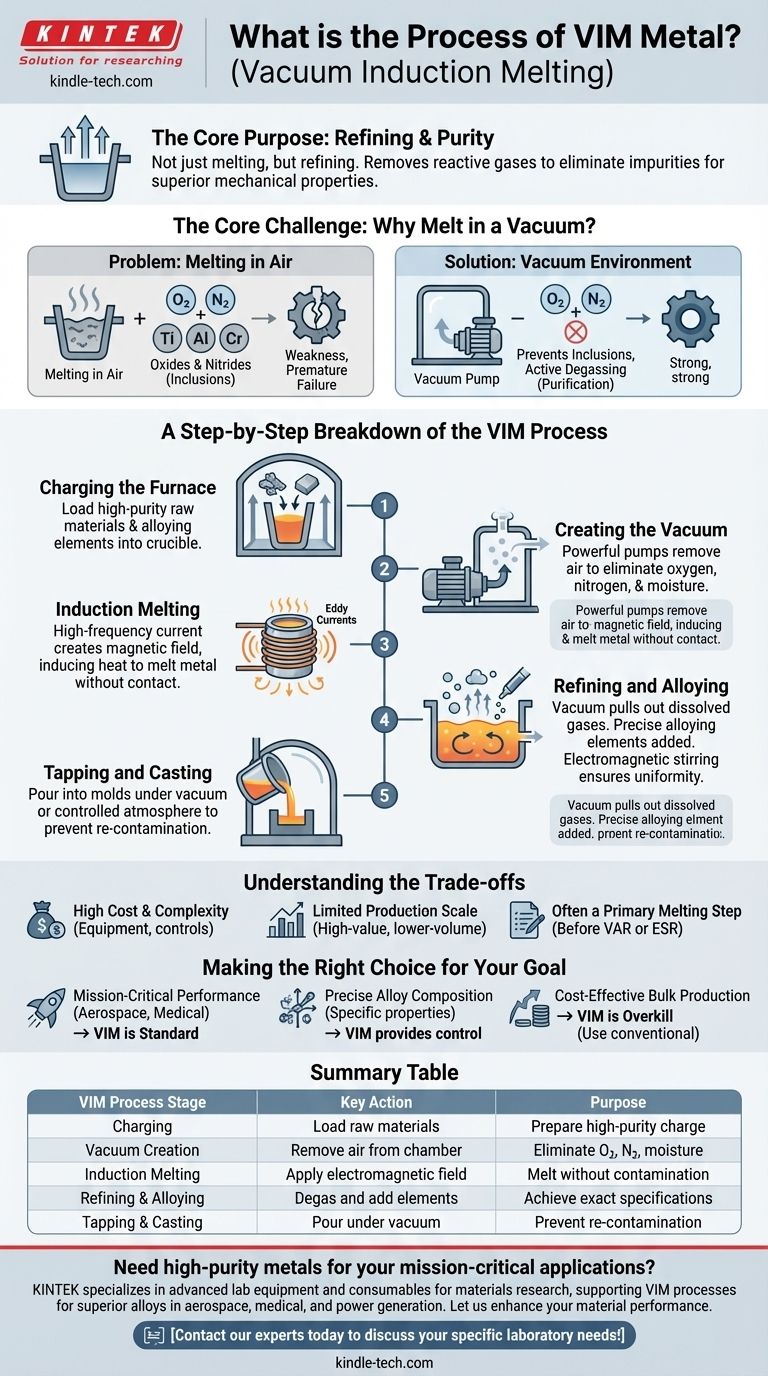

The Core Challenge: Why Melt in a Vacuum?

To understand VIM, you must first understand the problem with melting metal in the open air. The air we breathe is fundamentally hostile to high-performance molten metals.

The Problem with Reactive Elements

Many critical alloying elements—such as titanium, aluminum, and chromium—are highly reactive. When melted in air, they readily combine with oxygen and nitrogen to form oxides and nitrides.

The Impact of Impurities

These unwanted compounds get trapped in the metal as non-metallic inclusions. Inclusions act as microscopic stress points, compromising the material's integrity and leading to reduced fatigue life, poor ductility, and premature failure under stress.

The Goal of a Vacuum Environment

The VIM process solves this by removing the air. Operating under a vacuum prevents the formation of these inclusions. Furthermore, the vacuum actively pulls dissolved gases like hydrogen and nitrogen out of the liquid metal, a purification process known as degassing.

A Step-by-Step Breakdown of the VIM Process

The VIM process is a sequence of carefully controlled stages designed to maximize purity and compositional accuracy.

Step 1: Charging the Furnace

High-purity raw metals and alloying elements, known as the charge, are loaded into a ceramic crucible. This crucible sits inside a large, sealed vacuum chamber.

Step 2: Creating the Vacuum

Powerful pumps remove the air from the chamber, creating a vacuum. This critical step eliminates the oxygen, nitrogen, and moisture that would otherwise contaminate the metal.

Step 3: Induction Melting

A high-frequency electrical current is passed through a copper coil that wraps around the crucible. This creates a powerful magnetic field that induces electrical eddy currents within the metal charge. The resistance to these currents generates intense heat, melting the metal without any direct contact from a heat source.

Step 4: Refining and Alloying

As the metal melts, the vacuum pulls out dissolved gases. The electromagnetic field also naturally stirs the molten bath, ensuring it is uniform in temperature and composition. At this stage, operators can add precise amounts of other alloying elements through a vacuum-sealed port to meet exact chemical specifications.

Step 5: Tapping and Casting

Once the metal reaches the target chemistry and temperature, the crucible is tilted to pour (or tap) the molten alloy into molds. This entire step is performed while still under vacuum or in a controlled inert gas atmosphere to prevent any re-contamination before the metal solidifies into an ingot or casting.

Understanding the Trade-offs

While VIM produces superior materials, it is a specialized process with specific limitations. It is not the right choice for every application.

High Cost and Complexity

VIM is significantly more expensive than conventional air-melting. The required vacuum equipment, longer processing times, and sophisticated controls contribute to a higher operational cost.

Limited Production Scale

VIM furnaces are typically smaller than furnaces used for bulk steel production. This makes the process best suited for high-value, lower-volume materials rather than common structural metals.

Often a Primary Melting Step

For the most demanding applications, such as single-crystal turbine blades or rotating aerospace parts, VIM is just the first step. The ingot produced by VIM is often used as a high-purity electrode for a secondary refining process, such as Vacuum Arc Remelting (VAR) or Electroslag Remelting (ESR), to achieve an even higher level of quality.

Making the Right Choice for Your Goal

Selecting the VIM process is a strategic choice driven entirely by the performance requirements of the final component.

- If your primary focus is mission-critical performance: VIM is the standard for producing the superalloys used in aerospace engines, medical implants, and power generation turbines where material failure is not an option.

- If your primary focus is precise alloy composition: VIM provides unparalleled control for developing materials with highly specific magnetic, electronic, or chemical properties.

- If your primary focus is cost-effective bulk production: VIM is overkill; conventional air-melting or Argon Oxygen Decarburization (AOD) are far more suitable for less demanding applications.

Ultimately, choosing VIM is a decision to invest in material purity and precision to achieve unparalleled performance in the most demanding environments.

Summary Table:

| VIM Process Stage | Key Action | Purpose |

|---|---|---|

| Charging | Load raw materials into crucible | Prepare high-purity charge |

| Vacuum Creation | Remove air from chamber | Eliminate oxygen, nitrogen, moisture |

| Induction Melting | Apply electromagnetic field | Melt metal without contamination |

| Refining & Alloying | Degas and add precise elements | Achieve exact chemical specifications |

| Tapping & Casting | Pour into molds under vacuum | Prevent re-contamination during solidification |

Need high-purity metals for your mission-critical applications?

KINTEK specializes in advanced lab equipment and consumables for materials research and development. Our expertise supports processes like Vacuum Induction Melting, helping you achieve the precise alloy compositions and superior material properties required for aerospace, medical implants, and power generation.

Let us help you enhance your material performance and reliability. Contact our experts today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How do specialized industrial-grade small melting furnaces address challenges in precision jewelry casting? Expert Guide

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What are the disadvantages of direct core type induction furnace? High Standby Costs and Inflexibility

- What is a steel induction furnace? The Inside-Out Melting Technology for High-Purity Steel

- Does induction heating work on aluminum? Yes, with the right high-frequency equipment.

- What is the power of induction furnace? Unlock Precise Control and Efficiency for Your Lab

- What role does a Vacuum Induction Melting furnace play in 12% Cr martensitic steel? Achieve Ultra-Pure Alloy Control

- What is the difference between core type furnace and coreless induction furnace? Choose the Right Tool for Your Foundry