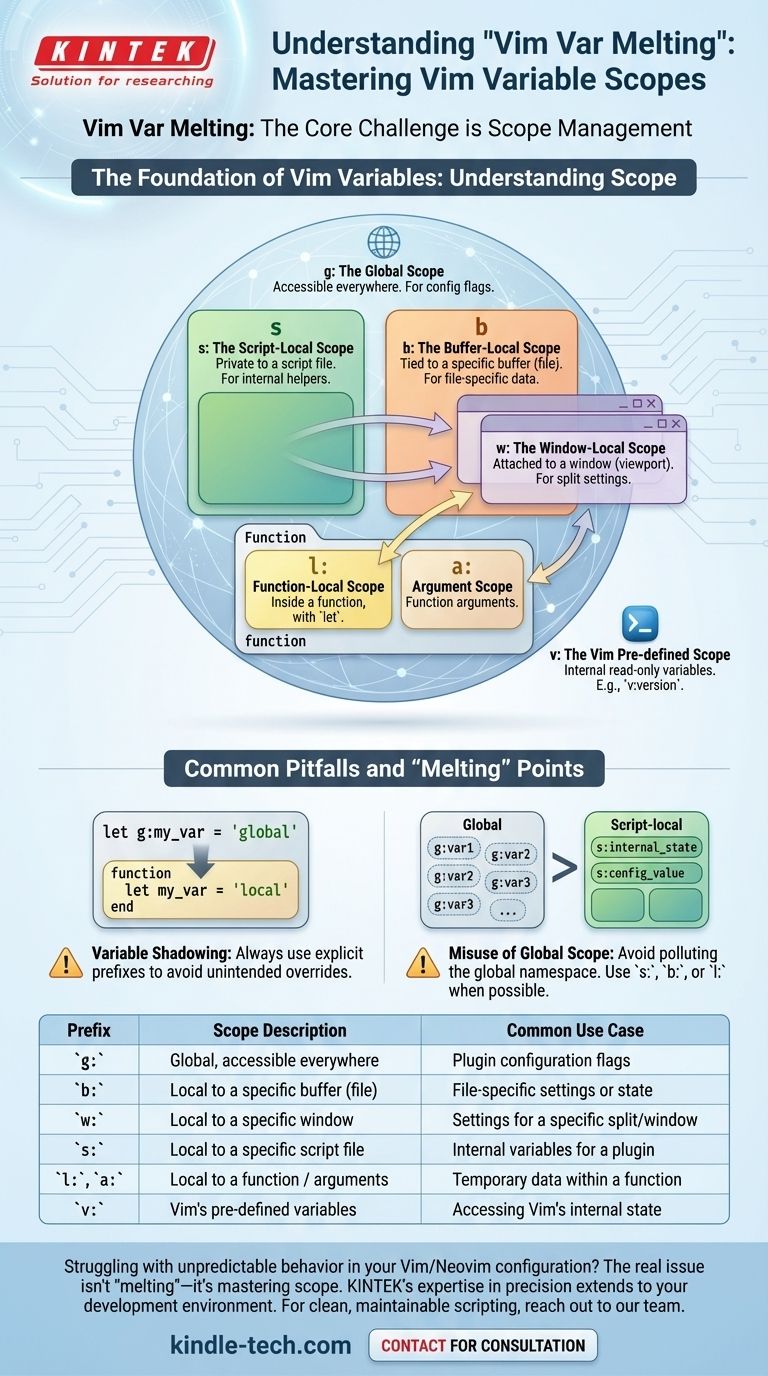

To be clear, "vim var melting" is not a standard or recognized technical process within the Vim/Neovim ecosystem. It is likely a misunderstanding, a mistranslation, or a "hallucinated" term for the fundamental way Vim manages, scopes, and resolves variables. The underlying concept you are likely seeking to understand is how Vim's variable scopes work and interact.

The core challenge in Vim scripting isn't "melting" variables, but managing their distinct scopes. Vim uses specific prefixes (like

g:,b:,s:) to define where a variable lives and who can access it, and mastering these prefixes is the key to writing predictable and bug-free configurations and plugins.

The Foundation of Vim Variables: Understanding Scope

In any programming environment, "scope" refers to the context in which a variable is accessible. Vim has a powerful, explicit system for this. A variable's name is prefixed to declare its scope.

g: The Global Scope

Global variables, prefixed with g:, are accessible everywhere. You can read and modify them from any script, function, command, or plugin.

They are best used for configuration flags that need to be accessed across your entire Vim session. For example, let g:my_plugin_enabled = 1.

b: The Buffer-Local Scope

Buffer-local variables (b:) are tied to a specific buffer, which usually corresponds to an open file.

This is extremely useful for storing information relevant only to that file, such as syntax settings or linter results. When you switch to another buffer (file), b:my_var will have a different value or may not exist at all.

w: The Window-Local Scope

Window-local variables (w:) are attached to a specific window (a viewport onto a buffer).

These are less common but are used when a setting needs to be specific to a visual split. For instance, you could have the same file open in two different windows (:vsplit) and have a w: variable that is different in each.

s: The Script-Local Scope

Script-local variables (s:) are private to a specific Vim script file (e.g., a file in your plugin/ directory).

This is the preferred scope for helper variables and internal functions within a plugin. It prevents your plugin's variables from colliding with variables from other scripts or the user's configuration.

l: and a: The Function-Local Scopes

Inside a function, variables defined with let are local to that function by default and are often explicitly prefixed with l:.

Arguments passed to a function are accessed with the a: prefix (e.g., a:my_argument). These are the most common scopes you will encounter when writing Vimscript functions.

v: The Vim Pre-defined Scope

Vim provides a set of its own internal variables for state and information, prefixed with v:.

These are typically read-only and give you information like the Vim version (v:version), the current error message (v:errmsg), or the count provided to a command (v:count).

Common Pitfalls and "Melting" Points

The confusion around "melting" likely comes from how these different scopes can interact or override one another, which can feel unpredictable if you are not aware of the rules.

Variable Shadowing

The most common issue is "shadowing." If you define a function-local variable let my_var = "local" and a global variable let g:my_var = "global" exists, the one without a prefix inside the function will refer to the local one.

This can create bugs where you intend to modify a global variable but instead modify a local one of the same name. Always be explicit with prefixes (g:, s:, etc.) to avoid this ambiguity.

The Misuse of Global Scope

A frequent mistake is to use global (g:) variables for everything. This pollutes the global namespace and dramatically increases the risk of one plugin interfering with another.

Unless a variable truly needs to be accessible everywhere as a user-facing setting, it should be kept in a more restrictive scope like script-local (s:) or buffer-local (b:).

Buffer vs. Window Complexity

The distinction between b: and w: variables can be subtle. Remember that a single buffer can be displayed in multiple windows.

If you change a b: variable in one window, it changes for all other windows viewing that same buffer. If you change a w: variable, it only affects that specific window.

How to Apply This to Your Goal

Your choice of variable scope directly impacts the correctness and robustness of your Vim configuration.

- If your primary focus is writing a plugin: Default to

s:variables for internal logic and expose configuration options to users withg:variables. Useb:variables for any state that is specific to a file being edited. - If your primary focus is writing a personal function in your

vimrc: Use function-local variables (l:) for temporary data. Only useg:if you are setting a configuration option that other parts of your setup need to read. - If your primary focus is debugging a script: Use the

:echocommand with the correct prefix (e.g.,:echo b:my_buffer_var) to inspect the value of a variable in its specific scope.

Ultimately, mastering Vim scripting is about controlling where your data lives and for how long.

Summary Table:

| Vim Variable Prefix | Scope Description | Common Use Case |

|---|---|---|

g: |

Global, accessible everywhere | Plugin configuration flags |

b: |

Local to a specific buffer (file) | File-specific settings or state |

w: |

Local to a specific window (viewport) | Settings for a specific split/window |

s: |

Local to a specific script file | Internal variables for a plugin |

l:, a: |

Local to a function, or function arguments | Temporary data within a function |

v: |

Vim's pre-defined, read-only variables | Accessing Vim's internal state (e.g., v:version) |

Struggling with unpredictable behavior in your Vim/Neovim configuration? The real issue isn't 'melting' variables—it's mastering their scope. KINTEK's expertise in precision and clarity extends beyond lab equipment. Let us help you apply the same rigorous logic to your development environment. For clean, maintainable, and powerful scripting, reach out to our team for a consultation today.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Which materials are used for high temperature applications? Choose the Right Material for Extreme Heat

- What is the process of plasma sputtering? A Guide to Precision Thin Film Deposition

- What are the different types of magnetron sputtering? A Guide to DC, RF, and HiPIMS for Your Lab

- What are some typical applications for oil-free diaphragm vacuum pumps? Ensure Process Purity in Your Lab

- Can aluminum be sputtered? Master the Process for High-Quality Thin Films

- What is preventive maintenance in a laboratory? A Proactive Strategy for Lab Reliability and Data Integrity

- What is the difference between wiped film and thin film? Unlock the Right Distillation Method for Your Process

- What are 2 examples of deposition in chemistry? From Frost to Soot Explained