At its core, a burnout furnace is a high-temperature oven with a single, critical purpose: to create a perfect, empty mold cavity for metal casting. Used extensively in dentistry and jewelry making, its job is to completely eliminate a wax pattern from a refractory mold, preparing it to receive molten metal.

The primary function of a burnout furnace is not to melt the casting metal, but to meticulously remove the wax or 3D-printed resin model from within an "investment" mold. This process, known as "burnout," creates a clean, hollow space that will become the final cast object.

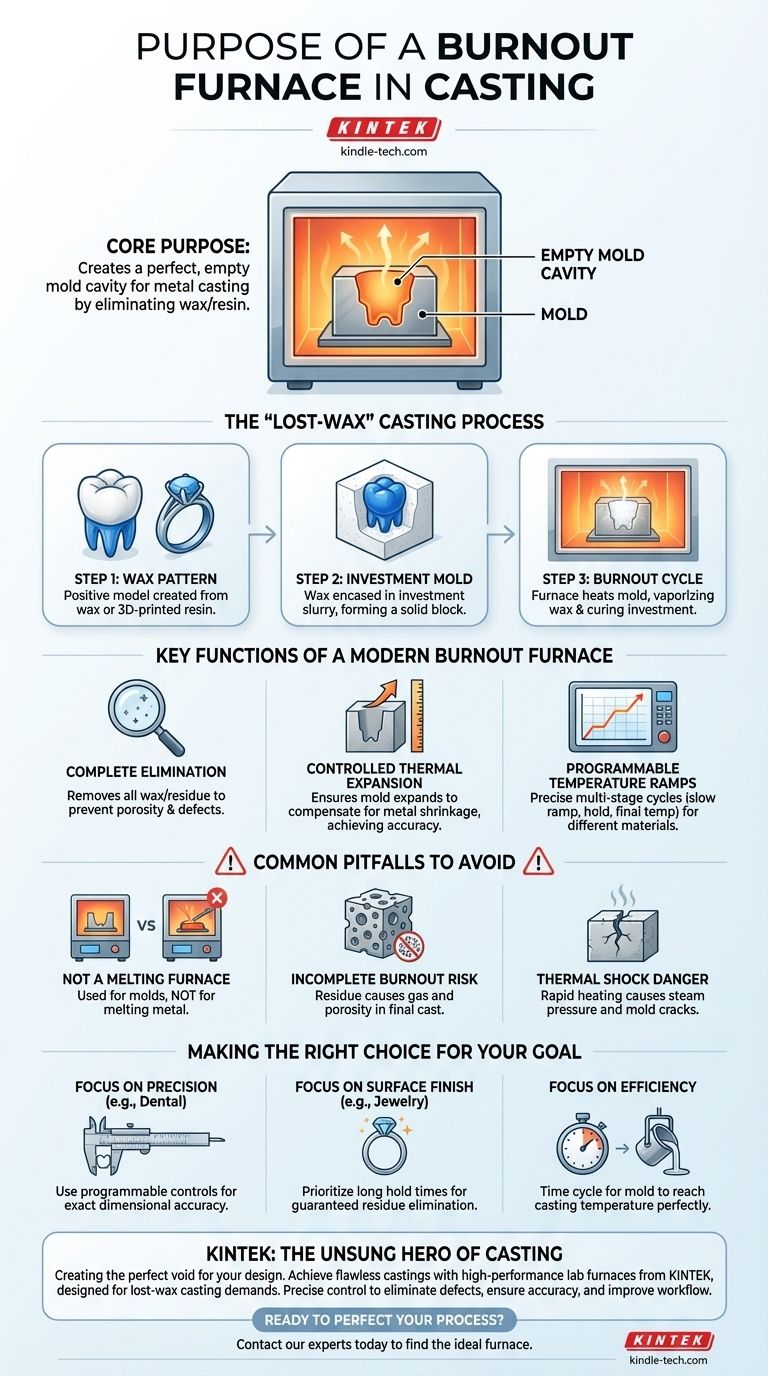

The Role of Burnout in the Casting Process

To understand the furnace's purpose, you must first understand its place in the "lost-wax" casting workflow. This process turns a delicate pattern into a durable metal object.

Step 1: The Wax Pattern

An object, such as a dental crown or a piece of jewelry, is first created in detail using a specialized wax or a castable 3D-printing resin. This is the positive model of the final piece.

Step 2: The Investment Mold

This wax pattern is surrounded by a ceramic-like slurry called investment. Once the investment hardens, it forms a solid block—a negative mold—with the wax pattern trapped inside.

Step 3: The Burnout Cycle

This is where the furnace performs its crucial role. The entire investment mold is placed inside the burnout furnace. The temperature is then raised according to a precise, pre-programmed schedule.

This cycle achieves two goals simultaneously:

- It melts and then vaporizes the wax pattern, allowing it to drain and burn away completely, leaving a hollow cavity.

- It heat-cures the investment material, making it strong enough to withstand the thermal shock of receiving molten metal.

Key Functions of a Modern Burnout Furnace

A burnout furnace is more than just a hot box; it is a precision instrument designed for control. Its success depends on managing temperature over time.

Complete Wax and Residue Elimination

The primary goal is to leave behind a perfectly clean cavity. Any remaining wax or carbon residue will cause porosity or surface defects in the final metal casting, compromising its integrity and finish.

Controlled Thermal Expansion

As the furnace heats the mold, the investment material expands. A properly programmed cycle ensures the mold expands to the correct dimensions to compensate for the shrinkage of the metal alloy as it cools. This is essential for achieving a dimensionally accurate final part.

Programmable Temperature Ramps

Different investment materials and waxes require different heating rates and temperatures. Modern furnaces allow technicians to program multi-stage cycles—a slow ramp-up to prevent the mold from cracking, a "hold" phase to ensure complete burnout, and a final hold at the target casting temperature.

Common Pitfalls to Avoid

Mistakes during the burnout stage are a primary cause of casting failures. Understanding the furnace's specific role is key to avoiding them.

Burnout Furnace vs. Melting Furnace

A burnout furnace prepares the mold. A separate melting furnace or torch is used to liquefy the metal that will be poured into the mold. Confusing the two or using a single furnace improperly for both functions is a recipe for failure.

The Risk of Incomplete Burnout

Rushing the cycle or not reaching a high enough temperature can leave carbon residue inside the mold. When molten metal hits this residue, it creates gases that result in porosity (tiny bubbles) within the final cast piece, making it weak.

The Danger of Thermal Shock

Heating the investment mold too quickly will cause the moisture within it to turn to steam too rapidly, generating pressure that cracks the mold. This will result in a "finned" or completely failed casting.

Making the Right Choice for Your Goal

The burnout cycle is a direct bridge between your design and your final product. How you manage it depends on your priority.

- If your primary focus is precision and fit (e.g., dental restorations): You must use a furnace with precise, programmable controls to perfectly manage mold expansion for dimensional accuracy.

- If your primary focus is a defect-free surface finish (e.g., high-end jewelry): Prioritize a cycle with a long enough hold at peak temperature to guarantee all residue is eliminated from the mold.

- If your primary focus is efficiency and throughput: Your goal is to time the burnout cycle so the mold reaches its target casting temperature at the exact moment your metal is ready to be cast.

Ultimately, the burnout furnace is the unsung hero of the casting process, creating the perfect void that allows your design to take its final, permanent form.

Summary Table:

| Key Function | Purpose |

|---|---|

| Complete Wax Elimination | Removes all wax/resin residue to prevent casting defects like porosity. |

| Mold Curing & Strengthening | Heat-treats the investment material to withstand molten metal. |

| Controlled Thermal Expansion | Ensures the mold expands correctly for dimensional accuracy in the final cast. |

| Programmable Temperature Cycles | Allows precise control over heating rates and hold times for different materials. |

Achieve flawless castings with a burnout furnace from KINTEK.

Whether you are in dental labs creating precise restorations or in jewelry making crafting intricate pieces, the right burnout cycle is critical to your success. KINTEK specializes in high-performance lab furnaces designed for the exacting demands of lost-wax casting.

Our furnaces offer the precise, programmable control you need to eliminate defects, ensure dimensional accuracy, and improve your workflow efficiency.

Ready to perfect your casting process? Contact our experts today to find the ideal burnout furnace for your laboratory's needs.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the components of a muffle furnace? Unlock the Core Systems for Precise, Safe Heating

- How do you perform calcination? Master Precise Thermal Treatment for Your Materials

- What is the temperature of furnace exhaust? A Key Indicator of Efficiency and Safety

- What precautions should be taken during muffle furnace? Essential Safety & Operational Guidelines

- Why is sintering important in ceramic processing? Achieve Dense, High-Performance Ceramic Parts