At its core, heat treatment is a highly controlled process used to deliberately alter a metal's physical properties. By carefully applying heat and cooling cycles, we can tailor a material's characteristics—such as its hardness, toughness, or ductility—to precisely match the demands of a specific engineering application, transforming a generic metal into a high-performance component.

The fundamental purpose of heat treating is not just to make a metal "stronger," but to achieve a specific, optimal balance between competing properties. It's about strategically trading a bit of one characteristic (like hardness) to gain a crucial amount of another (like toughness), ensuring the final part performs its job without failing.

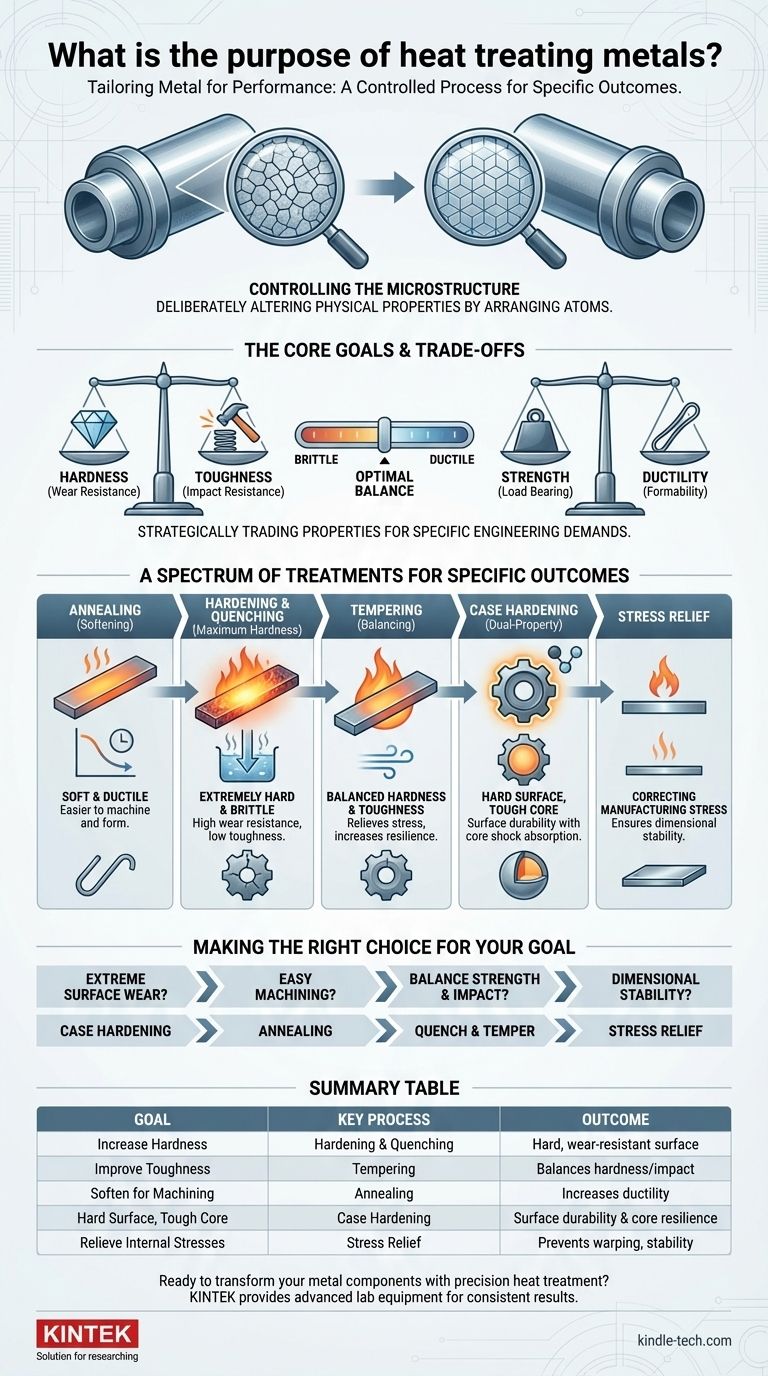

Beyond Raw Material: Tailoring Metal for Performance

A piece of metal as it comes from the mill or foundry is a blank slate. Its inherent properties are rarely ideal for demanding applications like gears, engine components, or structural beams. Heat treatment is the critical manufacturing step that unlocks a metal's true potential.

Controlling the Microstructure

The secret to heat treatment lies in manipulating the metal's internal crystal structure, known as its microstructure. Heating a metal above a critical temperature allows its atoms to rearrange. The speed and method of cooling then "lock in" a specific atomic arrangement, which directly determines the final mechanical properties.

The Primary Goals of Heat Treatment

Nearly all heat treatment processes are designed to modify one or more of the following key properties:

- Hardness: Resistance to scratching, wear, and indentation.

- Toughness: Ability to absorb energy and deform without fracturing.

- Ductility: Ability to be stretched or bent without breaking.

- Strength: Ability to withstand an applied load without deformation or failure.

- Elasticity: Ability to return to its original shape after a load is removed.

A Spectrum of Treatments for Specific Outcomes

Different goals require different processes. Each treatment is a unique recipe of temperature, time, and cooling designed to produce a specific result.

Softening for Easier Manufacturing (Annealing)

Annealing involves heating a metal and then cooling it very slowly. This process produces a soft, ductile material that is easy to machine, form, or cut. It essentially "resets" the metal, making it more workable for subsequent manufacturing steps.

Achieving Maximum Hardness (Hardening & Quenching)

To make a steel part extremely hard, it is heated to a high temperature and then rapidly cooled, or quenched, in a medium like water, oil, or air. This process creates a very hard but also very brittle microstructure. While highly resistant to wear, a quenched-only part is often too brittle for practical use.

Balancing Hardness and Toughness (Tempering)

Tempering is the essential follow-up to hardening. The hardened, brittle part is reheated to a lower temperature and held for a specific time. This process relieves internal stresses and reduces brittleness, significantly increasing the metal's toughness. The trade-off is a slight reduction in peak hardness.

Creating a Dual-Property Part (Case Hardening)

For components like gears or bearings, you need a very hard surface to resist wear but a tougher, more ductile core to absorb shock. Case hardening (or surface hardening) achieves this by altering the chemistry of only the surface layer, often by introducing carbon (carburising) or nitrogen. The part is then heat-treated, creating a hard "case" around a softer core.

Correcting for Manufacturing Stress (Stress Relief)

Processes like welding, machining, and cold forming create significant internal stresses within a metal. These hidden stresses can cause a part to warp over time or fail unexpectedly. Stress relieving, a low-temperature heat treatment, reduces these internal stresses without changing the metal's core properties, ensuring dimensional stability.

Understanding the Trade-offs

Heat treatment is not a magic bullet; it is a science of compromise. Understanding the inherent trade-offs is crucial for making sound engineering decisions.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in metallurgy. As you increase a metal's hardness, you almost invariably decrease its toughness, making it more brittle. The goal of a process like quenching and tempering is to find the perfect balance on this spectrum for the component's intended function.

Surface vs. Through-Hardness

It is not always necessary or desirable to make an entire component uniformly hard. A fully hardened bolt might be too brittle and could snap under load. Case hardening is a direct solution to this, allowing an engineer to get the best of both worlds: surface durability and core resilience.

Process Control is Everything

Heat treatment is a discipline of precision. Minor deviations in temperature, hold times, or cooling rates can lead to dramatically different and undesirable results. This is why processes are tightly controlled, often using specialized equipment like electric resistance furnaces or induction heating systems for localized surface treatments.

Making the Right Choice for Your Goal

Your choice of heat treatment process should be driven entirely by the final performance requirement of the component.

- If your primary focus is extreme surface wear resistance: Case hardening is the most effective solution, creating a durable exterior while maintaining a tough interior.

- If your primary focus is making a metal easy to machine or form: Annealing is the correct choice to maximize softness and ductility.

- If your primary focus is a balance of high strength and impact resistance: A carefully controlled quench and temper process will deliver the necessary hardness and toughness.

- If your primary focus is ensuring a part remains dimensionally stable after machining or welding: Stress relief is a critical step to prevent future distortion or failure.

By understanding these principles, you can see heat treatment for what it is: the art and science of transforming a simple metal into a precisely engineered material.

Summary Table:

| Goal | Key Process | Outcome |

|---|---|---|

| Increase Hardness & Wear Resistance | Hardening & Quenching | Creates a hard, wear-resistant surface |

| Improve Toughness & Reduce Brittleness | Tempering | Balances hardness with impact resistance |

| Soften for Machining/Forming | Annealing | Increases ductility and workability |

| Hard Surface, Tough Core | Case Hardening (e.g., Carburising) | Combines surface durability with core resilience |

| Relieve Internal Stresses | Stress Relief | Prevents warping and ensures dimensional stability |

Ready to transform your metal components with precision heat treatment? At KINTEK, we specialize in providing advanced lab equipment and consumables to support your heat treatment processes. Whether you're developing new alloys or optimizing existing treatments, our solutions ensure precise temperature control and consistent results.

Contact us today to discuss how KINTEK can enhance your laboratory's capabilities and help you achieve the perfect balance of material properties for your specific application.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are the advantages of multi-stage condensation vacuum equipment? Maximize Efficiency in Lead Anode Slime Processing

- What role does a high-temperature vacuum furnace play in the post-processing of Yttrium-modified Inconel 718 components?

- What is the temperature of sintered iron? Master the 1288°C Key to Strong Parts

- What does the heating rate during heat treatment depend on? Avoid Cracking and Distortion

- Is brazing done in a vacuum furnace? Achieve Superior Joint Strength and Purity

- What is a vacuum furnace used for? Unlock High-Purity Heat Treatment for Superior Materials

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints

- How does the cooling rate control of a furnace influence slow-cooled solid-state electrolytes? Achieve Crystal Perfection