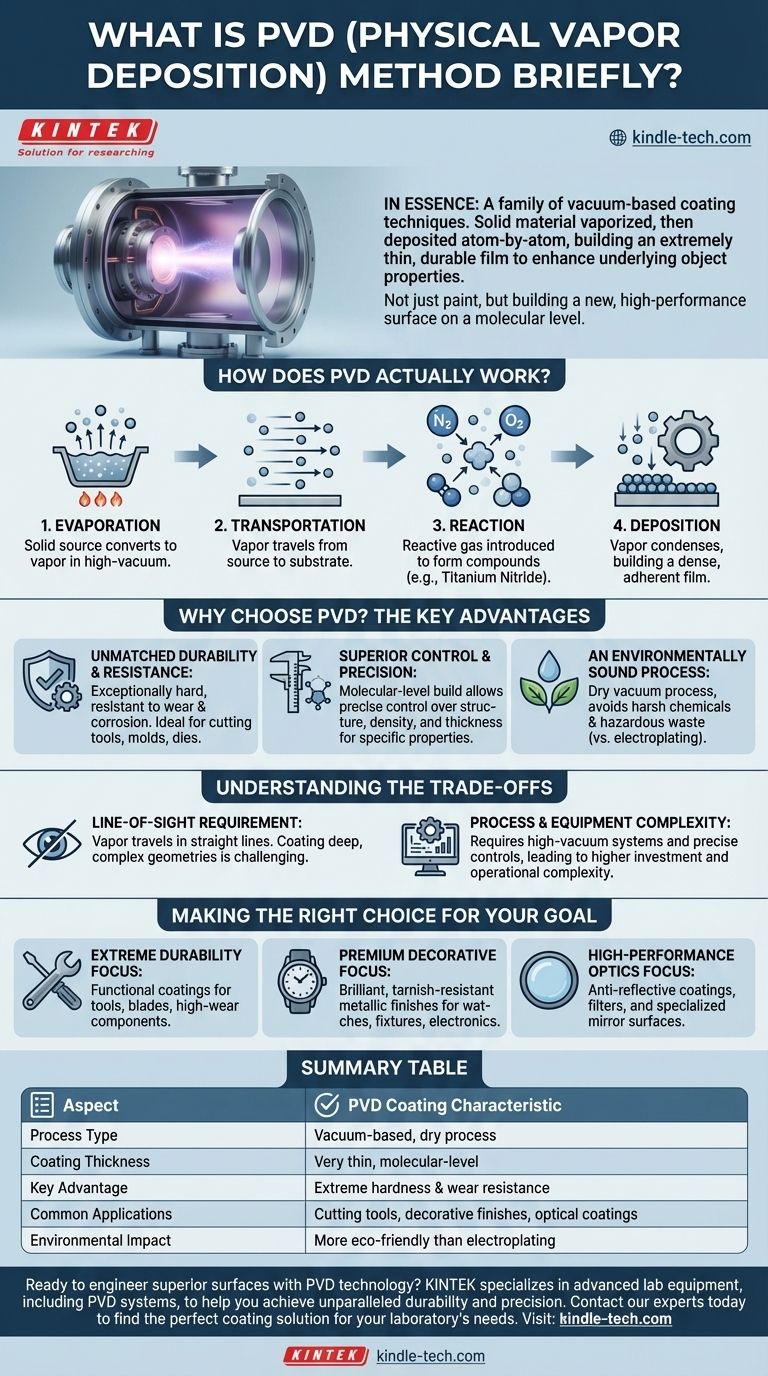

In essence, Physical Vapor Deposition (PVD) is a family of vacuum-based coating techniques where a solid material is vaporized and then deposited, atom by atom, onto a surface. This process creates an extremely thin yet highly durable film, fundamentally enhancing the properties of the underlying object.

The core principle of PVD is not simply applying a layer of paint, but rather building a new, high-performance surface on a molecular level. This precise control allows for the engineering of specific characteristics like extreme hardness, corrosion resistance, or a brilliant decorative finish.

How Does PVD Actually Work?

The PVD process is executed within a high-vacuum chamber to ensure purity and prevent contamination. It is universally broken down into four distinct stages.

Stage 1: Evaporation

First, a solid source material—the substance that will become the coating—is converted into a vapor. This is achieved inside the vacuum chamber using methods like heating or bombardment with ions.

Stage 2: Transportation

The vaporized atoms or molecules then travel from the source material across the vacuum chamber. They move in a straight line until they reach the object being coated, which is often called the substrate.

Stage 3: Reaction

For certain applications, a reactive gas like nitrogen, oxygen, or acetylene is introduced into the chamber. This gas reacts with the metal vapor to form a specific ceramic compound on the substrate's surface, such as titanium nitride for hardness.

Stage 4: Deposition

Finally, the vaporized material condenses onto the surface of the substrate. This builds up a thin, highly-adherent, and dense film, creating the final PVD coating.

Why Choose PVD? The Key Advantages

The atomic-level nature of the process gives PVD coatings several distinct and valuable characteristics that make them suitable for demanding applications.

Unmatched Durability and Resistance

PVD coatings are exceptionally hard and highly resistant to wear and corrosion. This makes them ideal for extending the life of cutting tools, blades, molds, and industrial dies.

Superior Control and Precision

Because the film is built one molecule at a time, engineers have incredible control over its structure, density, and thickness. This allows for the creation of coatings optimized for specific functional or optical properties.

An Environmentally Sound Process

Compared to traditional wet-plating methods like electroplating, PVD is a dry vacuum process. It avoids the use of harsh chemicals and the production of hazardous waste, making it a much more environmentally friendly option.

Understanding the Trade-offs

While powerful, the PVD method has inherent characteristics that make it unsuitable for every situation. Understanding these limitations is critical for making an informed decision.

Line-of-Sight Requirement

The vaporized atoms travel in a straight line from the source to the substrate. This means that coating the inside of complex, deep geometries or areas that are not in the direct line of sight can be extremely challenging.

Process and Equipment Complexity

PVD systems are sophisticated pieces of equipment. They require a high-vacuum chamber, powerful pumping systems, and precise electronic controls, leading to a significant initial investment and higher operational complexity than simpler coating methods.

Making the Right Choice for Your Goal

PVD is not a one-size-fits-all solution. Its value is unlocked when applied to the right problem.

- If your primary focus is extreme durability and wear resistance: PVD is an excellent choice for functional coatings on tools, blades, and high-wear industrial components.

- If your primary focus is a premium, long-lasting decorative finish: PVD provides a thin, brilliant, and tarnish-resistant metallic finish for items like watches, fixtures, and consumer electronics.

- If your primary focus is high-performance optics: The precision of PVD is essential for creating anti-reflective coatings, filters, and specialized mirror surfaces.

Ultimately, PVD is a critical tool for modern engineering, allowing us to build better surfaces rather than just covering them.

Summary Table:

| Aspect | PVD Coating Characteristic |

|---|---|

| Process Type | Vacuum-based, dry process |

| Coating Thickness | Very thin, molecular-level |

| Key Advantage | Extreme hardness & wear resistance |

| Common Applications | Cutting tools, decorative finishes, optical coatings |

| Environmental Impact | More eco-friendly than electroplating |

Ready to engineer superior surfaces with PVD technology? KINTEK specializes in advanced lab equipment, including PVD systems, to help you achieve unparalleled durability and precision for your tools, components, or research. Contact our experts today to find the perfect coating solution for your laboratory's needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition