The primary raw material for an induction furnace is metal. This includes a wide range of ferrous and non-ferrous metals, with the specific choice depending on the final product. For steel production, the charge is typically a mix of sponge iron (up to 90%) and pig iron.

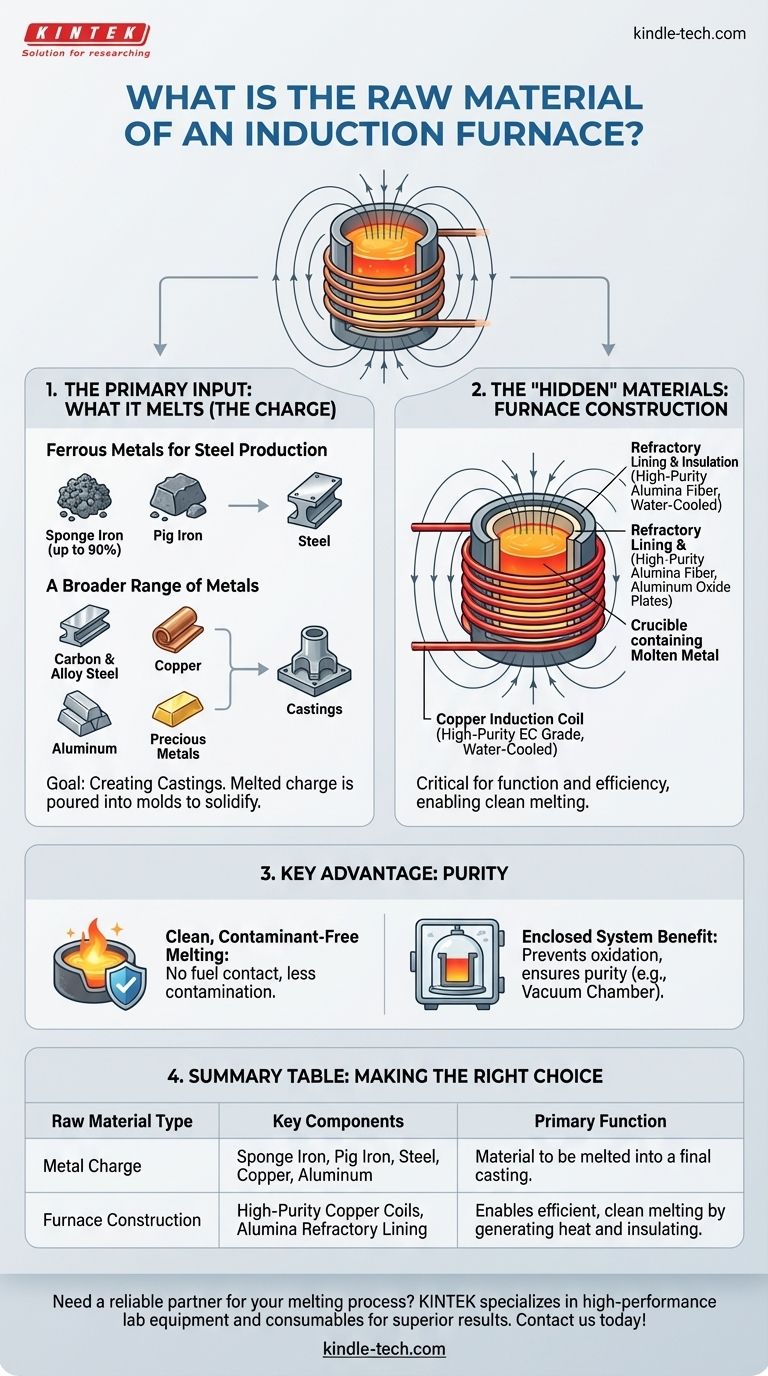

While the most direct answer is "metal," a true understanding requires looking at two sets of "raw materials": the metals that are melted (the charge) and the advanced materials used to construct the furnace itself, which enable the clean and efficient melting process.

The Primary Input: What an Induction Furnace Melts

The induction furnace is fundamentally a tool for melting. Its versatility allows it to handle a wide array of metals, making it a cornerstone of modern foundries.

Ferrous Metals for Steel Production

The most common application is melting iron-based metals.

The primary charge for producing new steel consists of sponge iron, which is derived from iron ore, and a smaller amount of pig iron. This mix is melted down and refined to create various grades of steel.

A Broader Range of Metals

Beyond basic steel, induction furnaces are adept at melting various other metals.

This includes carbon steel, alloy steel, and special steels, as well as non-ferrous metals like copper, aluminum, and even precious metals. The choice of input material is dictated entirely by the desired output.

The Goal: Creating Castings

The purpose of melting these raw materials is to produce a finished part.

Once the metal charge reaches a liquid state, it is poured into a mold. After it cools and solidifies, the final product, known as a casting, is removed.

The "Hidden" Raw Materials: Building the Furnace Itself

To fully grasp the technology, you must also consider the critical materials used to construct the furnace. These components are essential for the furnace's function and efficiency.

The Copper Induction Coil

The heart of the furnace is the induction coil, which generates the powerful magnetic field that heats the metal.

This coil is constructed from high-purity EC Grade copper tubes. Water is continuously circulated through these tubes to keep the coil from overheating during operation.

The Refractory Lining and Insulation

Containing molten metal at extreme temperatures requires highly advanced materials.

The furnace lining is made of refractory materials like high-purity alumina fiber and light hollow aluminum oxide plates. These materials can withstand high temperatures, provide excellent thermal insulation, and prevent the furnace shell from melting.

Understanding the Key Advantage: Purity

The construction and operation of an induction furnace offer a significant advantage over traditional fuel-fired furnaces. This is a direct result of the materials and principles involved.

Clean, Contaminant-Free Melting

Because heat is generated directly within the metal via an electromagnetic field, there is no contact with burning fuel or combustion gases.

This leads to a much cleaner melt with significantly less contamination. This purity is critical when producing high-specification alloys and special steels.

The Benefit of an Enclosed System

The design allows the melting process to occur in a tightly controlled environment.

Induction furnaces can operate in a normal atmosphere or be enclosed within a vacuum chamber. This prevents oxidation and other atmospheric reactions, further ensuring the purity of the final metal casting.

Making the Right Choice for Your Goal

The "raw material" you are concerned with depends on your objective—whether you are producing metal, or understanding the technology that makes it possible.

- If your primary focus is producing steel: Your raw materials are a carefully measured charge of sponge iron and pig iron.

- If your primary focus is high-purity castings: Your raw material could be copper, aluminum, or special alloys, and you are leveraging the furnace's clean-melting capabilities.

- If your primary focus is understanding the technology: You must consider the copper coil and alumina lining as the critical "raw materials" that define the furnace's performance.

Ultimately, a complete view of an induction furnace requires looking beyond the input metal to appreciate the advanced materials that enable the entire process.

Summary Table:

| Raw Material Type | Key Components | Primary Function |

|---|---|---|

| Metal Charge | Sponge Iron, Pig Iron, Steel, Copper, Aluminum | The material to be melted into a final casting. |

| Furnace Construction | High-Purity Copper Coils, Alumina Refractory Lining | Enables efficient, clean melting by generating heat and insulating the furnace. |

Need a reliable partner for your melting process?

KINTEK specializes in high-performance lab equipment and consumables, serving the precise needs of laboratories and foundries. Whether you are melting specialty alloys or require durable furnace components, our expertise ensures you achieve superior results with maximum efficiency and purity.

Contact us today to discuss how our solutions can enhance your operations!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications