The refractory material in a rotary kiln is a heat-resistant lining designed to insulate the steel shell from extreme internal temperatures. It is not one specific material, but rather a category of materials chosen based on the kiln's specific application, operating temperature, and the chemical properties of the substance being processed.

The choice of refractory is a critical engineering decision that dictates a kiln's operational efficiency, its service life, and its suitability for a specific industrial process. It serves the dual purpose of protecting the equipment and enabling the process itself.

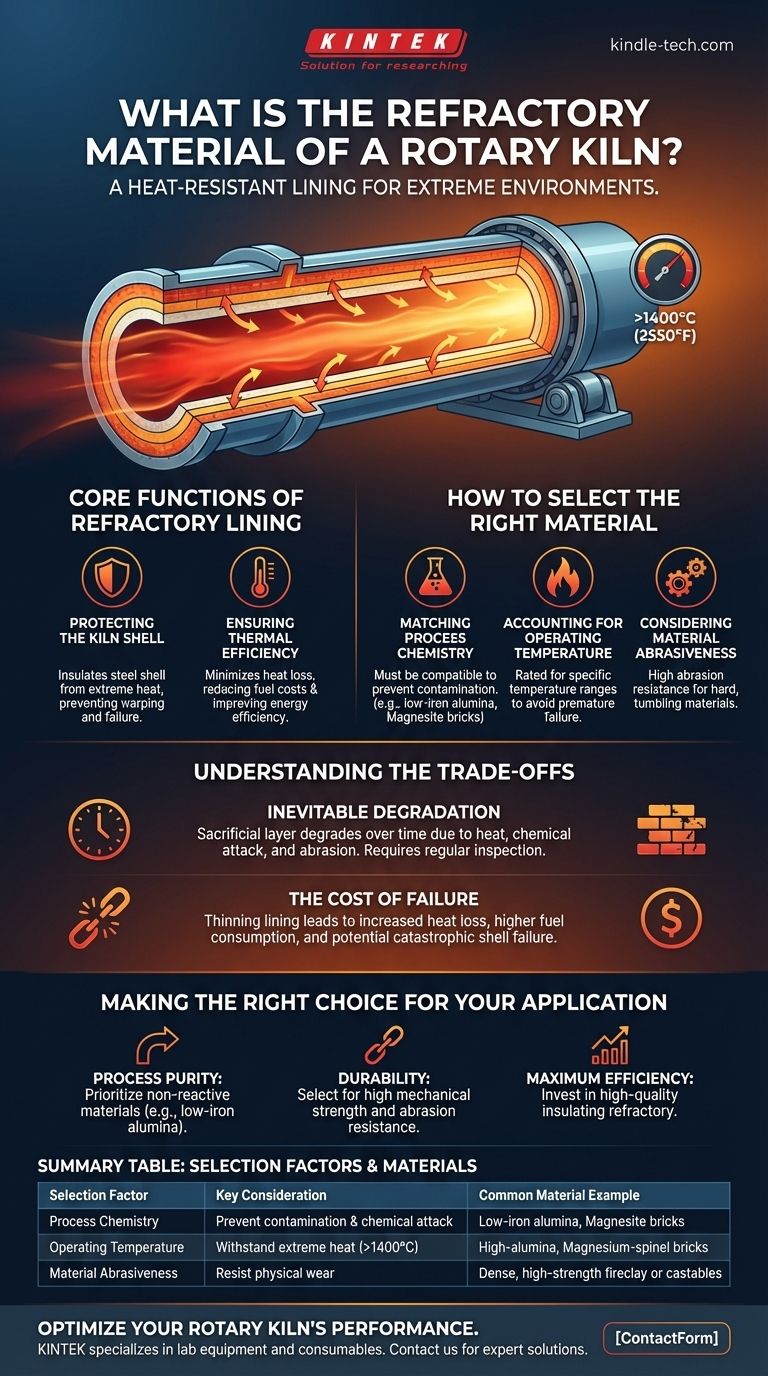

The Core Functions of Refractory Lining

A refractory lining is essential for any direct-fired rotary kiln, where it performs two fundamental jobs.

Protecting the Kiln Shell

The primary function of refractory is to act as a thermal barrier. It protects the outer steel shell of the kiln from the intense heat generated inside, which can often exceed 1400°C (2550°F).

Without this lining, the high temperatures would quickly cause the steel shell to warp, weaken, and ultimately fail, leading to catastrophic equipment damage.

Ensuring Thermal Efficiency

By insulating the kiln, the refractory minimizes heat loss to the surrounding environment. This is crucial for maintaining a stable and consistent internal temperature.

Proper heat retention reduces the amount of fuel required to sustain the process, directly lowering operating costs and improving overall energy efficiency. This is why refractory is specific to direct-fired kilns; adding it to an indirect-fired kiln would counterproductively insulate the material from its external heat source.

How to Select the Right Refractory Material

The selection process is a careful balance of chemical, thermal, and physical demands. There is no universal "best" refractory; the ideal choice is always specific to the application.

Matching Material to Process Chemistry

The chemical composition of the refractory must be compatible with the material being processed. A chemical reaction between the refractory and the process material can lead to contamination of the final product and rapid degradation of the lining.

For example, iron ore reduction kilns often use low-iron alumina or magnesium-spinel bricks to prevent unwanted iron reactions. In contrast, cement production kilns might use magnesite bricks due to their compatibility with the clinkering process.

Accounting for Operating Temperature

Refractory materials are rated for specific temperature ranges. Choosing a material with an inadequate temperature rating will lead to premature failure. The expected peak temperature inside the kiln is a primary factor in narrowing down material options.

Considering Material Abrasiveness

The physical properties of the material being processed also influence the choice. Hard, abrasive materials like certain ores will physically wear down the refractory lining over time through tumbling action.

In these cases, a refractory with high abrasion resistance is necessary to ensure a reasonable service life and prevent frequent and costly relining projects.

Understanding the Trade-offs and Degradation

Choosing and maintaining refractory involves balancing performance, cost, and lifespan. Ignoring these factors leads to inefficiency and operational risk.

The Inevitable Degradation

No refractory lining lasts forever. It is a sacrificial layer that is designed to degrade slowly over time due to a combination of high heat, chemical attack, and physical abrasion.

Regular inspections are critical to monitor the thickness and condition of the lining.

The Cost of Failure

As the refractory lining thins, its insulating properties diminish. This leads to increased heat loss through the kiln shell, forcing the system to consume more fuel to maintain the required temperature.

If ignored, this degradation can eventually expose the steel shell to damaging heat, risking a complete structural failure of the kiln. The cost of an unplanned shutdown and shell repair far exceeds the cost of proactive refractory maintenance.

Making the Right Choice for Your Application

Selecting the correct refractory is fundamental to optimizing your kiln's performance and longevity. Your decision should be guided by your primary operational goal.

- If your primary focus is process purity and chemical compatibility: Prioritize a refractory material whose chemical composition (e.g., low-iron alumina) will not react with or contaminate your product.

- If your primary focus is durability against abrasive materials: Select a refractory known for high mechanical strength and abrasion resistance to maximize service life and reduce downtime.

- If your primary focus is maximum thermal efficiency: Invest in a high-quality insulating refractory with the correct thickness to minimize heat loss and reduce long-term fuel costs.

Ultimately, the refractory lining is the unseen workhorse that makes a safe, efficient, and reliable rotary kiln operation possible.

Summary Table:

| Selection Factor | Key Consideration | Common Material Example |

|---|---|---|

| Process Chemistry | Prevent contamination & chemical attack | Low-iron alumina, Magnesite bricks |

| Operating Temperature | Withstand extreme heat (>1400°C) | High-alumina, Magnesium-spinel bricks |

| Material Abrasiveness | Resist physical wear from tumbling | Dense, high-strength fireclay or castables |

Optimize your rotary kiln's performance and protect your investment. The right refractory lining is critical for thermal efficiency, product purity, and equipment longevity. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert solutions for high-temperature processes. Let our experts help you select the perfect refractory material for your specific application. Contact us today for a consultation!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

People Also Ask

- What is the process of carbon regeneration? Restore Spent Carbon for Cost-Effective, Sustainable Use

- How fast is pyrolysis? A Guide to Controlling Process Speed for Your Desired Product

- What are the benefits of microwave pyrolysis? Achieve Faster, More Efficient Waste-to-Value Conversion

- What factors are considered when determining the size of a rotary kiln? Expert Sizing Guide for Efficiency

- What are the key components of a rotary kiln system? Optimize Your High-Volume Thermal Processing Efficiency

- What are the disadvantages of rotary kiln? High Costs, Maintenance, and Inefficiency Explained

- How does a rotary kiln rotate? Discover the Core Mechanics That Drive Thermal Processing

- How does the rotational frequency of a graphite drum influence aluminum bronze castings? Master SHS Process Precision