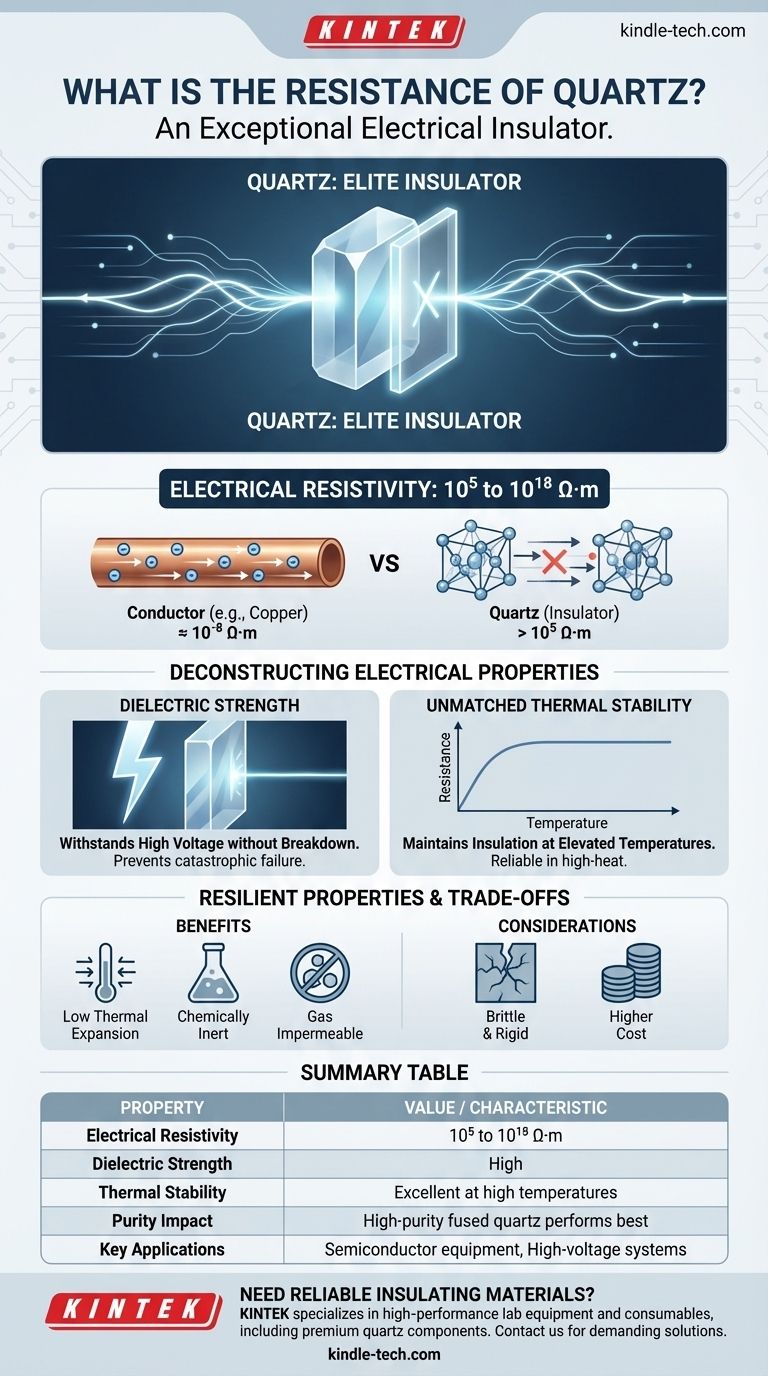

As a definitive answer, quartz is an exceptional electrical insulator, not a conductor. Its electrical resistivity is extremely high, typically falling within a vast range of 10⁵ to 10¹⁸ ohm-meters (Ω·m). This property, combined with its stability at high temperatures, makes it one of the most reliable insulating materials used in demanding applications.

The critical takeaway is not just the high resistance of quartz, but its unique ability to maintain that elite insulating performance under conditions—like extreme heat and high voltage—where lesser materials would fail.

Deconstructing the Electrical Properties of Quartz

To fully appreciate why quartz is chosen for critical components, we must look beyond a single number and understand the properties that define its electrical character.

Understanding Electrical Resistivity

The resistivity value, from 10⁵ to 10¹⁸ Ω·m, places quartz firmly in the top tier of electrical insulators.

For context, a conductor like copper has a resistivity of about 10⁻⁸ Ω·m. Quartz is engineered to do the exact opposite: to prevent the flow of electrical current as effectively as possible.

The wide range in its measured resistivity is primarily due to variations in the material's purity and crystalline structure. Fused quartz, which is synthetically produced to be chemically pure, will exhibit resistivity at the higher end of this scale.

More Than Resistance: Dielectric Strength

The references also highlight quartz's high dielectric strength. This is a separate but equally important property.

While resistivity measures the opposition to current flow, dielectric strength measures a material's ability to withstand a strong electric field without breaking down or allowing an arc to form.

This makes quartz invaluable for high-voltage applications, where it serves not just to stop leaks of current but to prevent catastrophic electrical failure.

Why Quartz Excels in Demanding Environments

A material's datasheet value is only useful if it holds true in a real-world environment. This is where quartz truly distinguishes itself from other insulators.

Unmatched Thermal Stability

Many materials see their insulating properties degrade significantly as temperatures rise. Quartz, however, maintains its excellent electrical resistance even at elevated temperatures.

This thermal stability ensures predictable and reliable performance in components that operate in high-heat environments, such as semiconductor processing equipment or high-power electronics.

A Package of Resilient Properties

The electrical performance of quartz is supported by a suite of other robust characteristics.

It has low thermal expansion, making it resistant to thermal shock. It is also chemically pure and largely inert, allowing it to be used in corrosive environments without degrading. Its impermeability to gases and extreme rigidity further enhance its reliability.

Understanding the Trade-offs

No material is perfect for every situation. Objectivity requires acknowledging the practical limitations of quartz.

Performance Depends on Purity

The exceptional properties described here apply primarily to high-purity fused quartz. Using a lower-grade, less pure form of quartz will result in diminished electrical and thermal performance. The specific grade of the material is a critical factor in its application.

Brittleness and Fabrication

Like many ceramics, quartz is rigid but brittle. It can be more difficult and expensive to machine into complex shapes compared to polymers or other insulating materials. This can be a significant constraint in mechanical design.

Cost Consideration

High-purity quartz is a premium material. Its production is an energy-intensive process, making it more expensive than common insulators like alumina ceramics or high-performance plastics. Its use is typically reserved for applications where its specific benefits justify the cost.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is maximum insulation in harsh environments: Quartz is the superior choice for its combination of high resistivity and stability at extreme temperatures and in corrosive settings.

- If your primary focus is high-voltage reliability: The exceptional dielectric strength of quartz is a non-negotiable feature for preventing electrical breakdown in high-field applications.

- If your primary focus is cost-sensitivity or mechanical flexibility: You may want to consider alternative materials like high-performance polymers or other ceramics if the operational environment is less demanding.

Ultimately, selecting quartz is a decision to prioritize unwavering electrical and thermal performance where reliability is paramount.

Summary Table:

| Property | Value / Characteristic |

|---|---|

| Electrical Resistivity | 10⁵ to 10¹⁸ Ω·m |

| Dielectric Strength | High |

| Thermal Stability | Excellent at high temperatures |

| Purity Impact | High-purity fused quartz performs best |

| Key Applications | Semiconductor equipment, high-voltage systems |

Need a reliable insulating material for your laboratory equipment? KINTEK specializes in high-performance lab equipment and consumables, including components made from premium materials like quartz. Our expertise ensures you get the right solutions for demanding environments, from semiconductor processing to high-voltage applications. Contact us today to discuss how we can support your laboratory's specific needs with precision and reliability.

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Electrode Polishing Material for Electrochemical Experiments

People Also Ask

- What can carbon nanotubes be used for? Unlock Superior Performance in Batteries & Materials

- What are the material properties of carbon paper? Unlocking High Conductivity & Porosity for Your Lab

- What is the ideal operating environment for a glassy carbon sheet? Ensure Optimal Performance and Longevity

- What are 3 products that carbon nanotubes can be used in? Enhancing Batteries, Tires, and Composites

- What are the common applications for carbon cloth? Unlock Its Potential in Energy & Electrochemical Systems