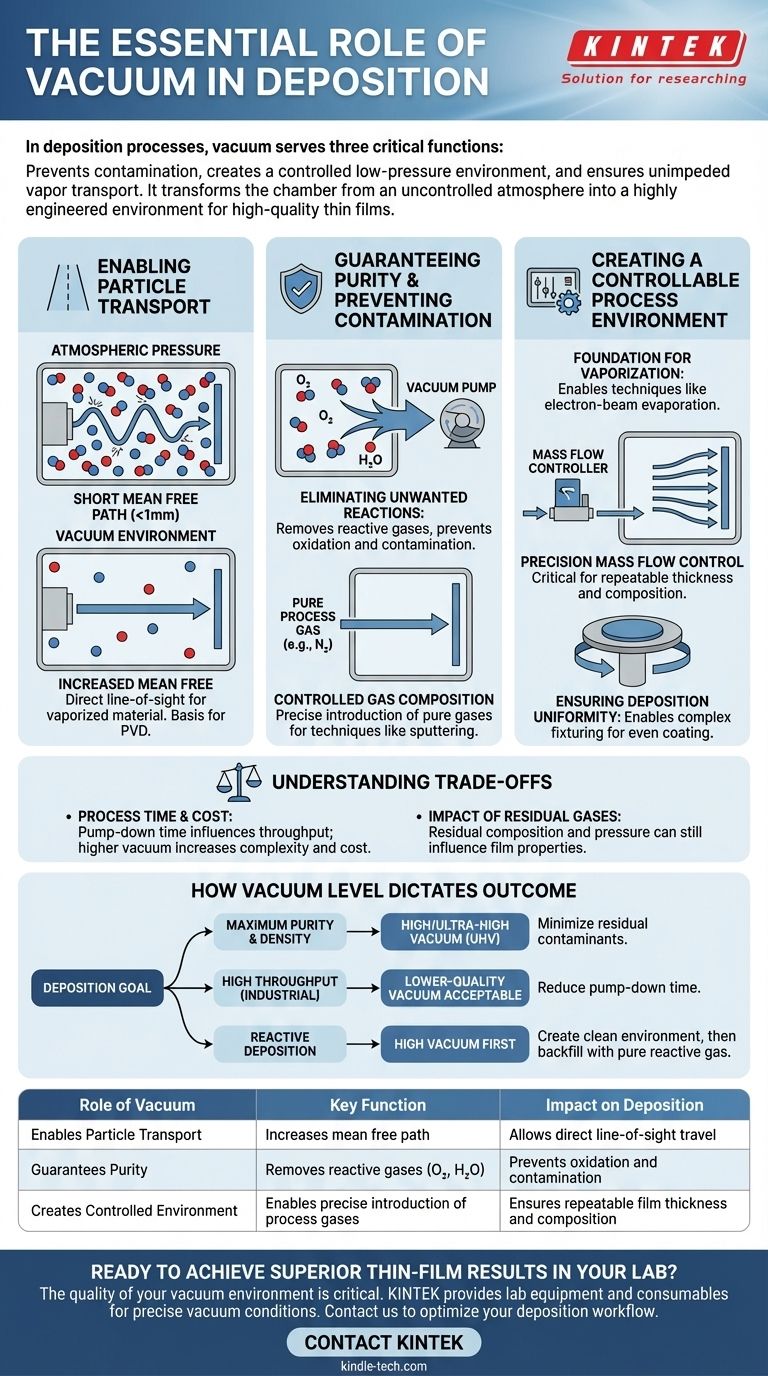

In deposition processes, the vacuum serves three critical functions: it prevents contamination by removing unwanted atmospheric gases, it creates a controlled, low-pressure environment for generating and manipulating vapors, and it ensures vaporized material can travel unimpeded from the source to the substrate. Without a vacuum, most modern thin-film deposition would be chemically and physically impossible.

The essential role of a vacuum is to transform the deposition chamber from an uncontrolled, reactive atmosphere into a highly engineered environment. It is not merely an empty space, but the fundamental ingredient that enables the purity, transport, and control required for creating high-quality thin films.

Enabling Particle Transport: The Mean Free Path

The Problem at Atmospheric Pressure

At standard atmospheric pressure, the air is dense with molecules like nitrogen, oxygen, and water vapor. These particles are in constant, random motion.

A vaporized atom from a deposition source would collide with these air molecules billions of times per second. Its mean free path—the average distance it can travel before a collision—is less than a millimeter.

The Vacuum Solution

By pumping out the vast majority of air molecules, a vacuum dramatically increases the mean free path.

This allows the vaporized coating material to travel in a straight, uninterrupted line from the source to the substrate. This direct line-of-sight travel is the basis for almost all physical vapor deposition (PVD) techniques.

Guaranteeing Purity and Preventing Contamination

Eliminating Unwanted Reactions

Many materials, especially when heated to the point of vaporization, are highly reactive. In open air, they would instantly oxidize or form other compounds, contaminating the film and altering its properties.

A vacuum removes these reactive gases, most notably oxygen and water vapor, creating a chemically inert environment. This ensures the deposited film is composed purely of the intended source material.

Controlling Gas and Vapor Composition

Once an initial vacuum is established, the chamber becomes a blank slate. This allows for the precise introduction of specific, high-purity gases needed for the process.

For techniques like sputtering or reactive deposition, the vacuum makes it possible to create a controlled, low-pressure plasma environment or to introduce a specific reactive gas (like nitrogen to create titanium nitride) without fear of contamination from the atmosphere.

Creating a Controllable Process Environment

The Foundation for Vaporization

Many methods used to generate vapors, such as electron-beam evaporation, can only function in a vacuum. The high-energy electron beams would scatter and dissipate in the presence of air.

Precision Mass Flow Control

The low-pressure environment enables extremely precise control over the amount of process gas or vapor entering the chamber. This control over mass flow is critical for achieving repeatable film thickness, composition, and material properties.

Ensuring Deposition Uniformity

Inside the vacuum, substrates are often held by complex fixturing that rotates or moves them relative to the vapor source.

This motion ensures the coating is applied evenly across complex surfaces or over many substrates at once. Such controlled mechanical movement would be impractical without the low-particle-density environment of a vacuum.

Understanding the Trade-offs

Process Time and Throughput

Achieving a high-quality vacuum is not instantaneous. The "pump-down" time required to remove atmospheric gases can be a significant portion of the total process cycle.

The complexity of the fixturing and the size of the chamber directly influence this pump-down time, creating a trade-off between substrate capacity and overall throughput.

Equipment Complexity and Cost

Vacuum systems—including chambers, pumps, valves, and gauges—are complex and expensive to purchase, operate, and maintain. The higher the desired vacuum level (e.g., ultra-high vacuum), the greater the cost and complexity.

The Impact of Residual Gases

No vacuum is perfect. There will always be some residual gas left in the chamber. The composition and pressure of this gas can still subtly influence the properties of the deposited film, making the quality of the vacuum a critical process parameter.

How Vacuum Level Dictates Your Outcome

The choice of vacuum level is a strategic decision based on the goals of your deposition process.

- If your primary focus is maximum film purity and density: You must use a high or ultra-high vacuum (UHV) to minimize the incorporation of residual gas contaminants into your film.

- If your primary focus is high throughput for industrial coating: A lower-quality vacuum may be acceptable to reduce pump-down time, provided the coating material is not highly reactive with residual air or water.

- If you are performing reactive deposition: A high vacuum is first needed to create a clean environment, which is then backfilled with a precisely controlled amount of a pure reactive gas.

Ultimately, the vacuum is the invisible but essential foundation upon which all modern thin-film technology is built.

Summary Table:

| Role of Vacuum | Key Function | Impact on Deposition |

|---|---|---|

| Enables Particle Transport | Increases mean free path for vaporized material | Allows direct line-of-sight travel from source to substrate |

| Guarantees Purity | Removes reactive gases (oxygen, water vapor) | Prevents oxidation and contamination of the film |

| Creates Controlled Environment | Enables precise introduction of process gases | Ensures repeatable film thickness and composition |

Ready to achieve superior thin-film results in your lab?

The quality of your vacuum environment is critical to the success of your deposition processes. KINTEK specializes in providing the lab equipment and consumables you need to create and maintain the precise vacuum conditions essential for high-purity coatings.

Contact us today to discuss how our solutions can help you optimize your deposition workflow, improve film quality, and increase throughput.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the purpose of using a vacuum furnace for diamond composites? Achieve High-Density Material Consolidation

- Why is a vacuum drying oven required for PEO-based SPE? Ensure Anhydrous Stability in Solid-State Battery Prep

- Why is a high-precision heat treatment furnace necessary for maraging steel? Ensure Peak SLM Part Performance

- What is the function of the furnace in the laboratory? A Tool for Precise Thermal Transformation

- What is the arc melting method for alloy preparation? A Guide to High-Volume Metal Melting

- What is the necessity of heat treatment after carburizing? Unlock Superior Hardness and Toughness

- What are the two purposes of case hardening? Achieve Superior Wear and Impact Resistance

- What are the applications of a furnace? From Industrial Production to Scientific R&D