In deposition processes, the primary role of a vacuum is to create an ultra-clean and precisely controlled environment. By evacuating a chamber, we systematically remove atmospheric gases and other contaminants. This act of removal is fundamental to ensuring the purity of the final film and enabling precise control over the pressure, composition, and flow of the gases required for the deposition itself.

The function of a vacuum is not merely to create emptiness, but to establish absolute control over the microscopic world. By removing atmospheric interference, you gain the ability to dictate a film's purity, structure, and uniformity, which is impossible under normal atmospheric conditions.

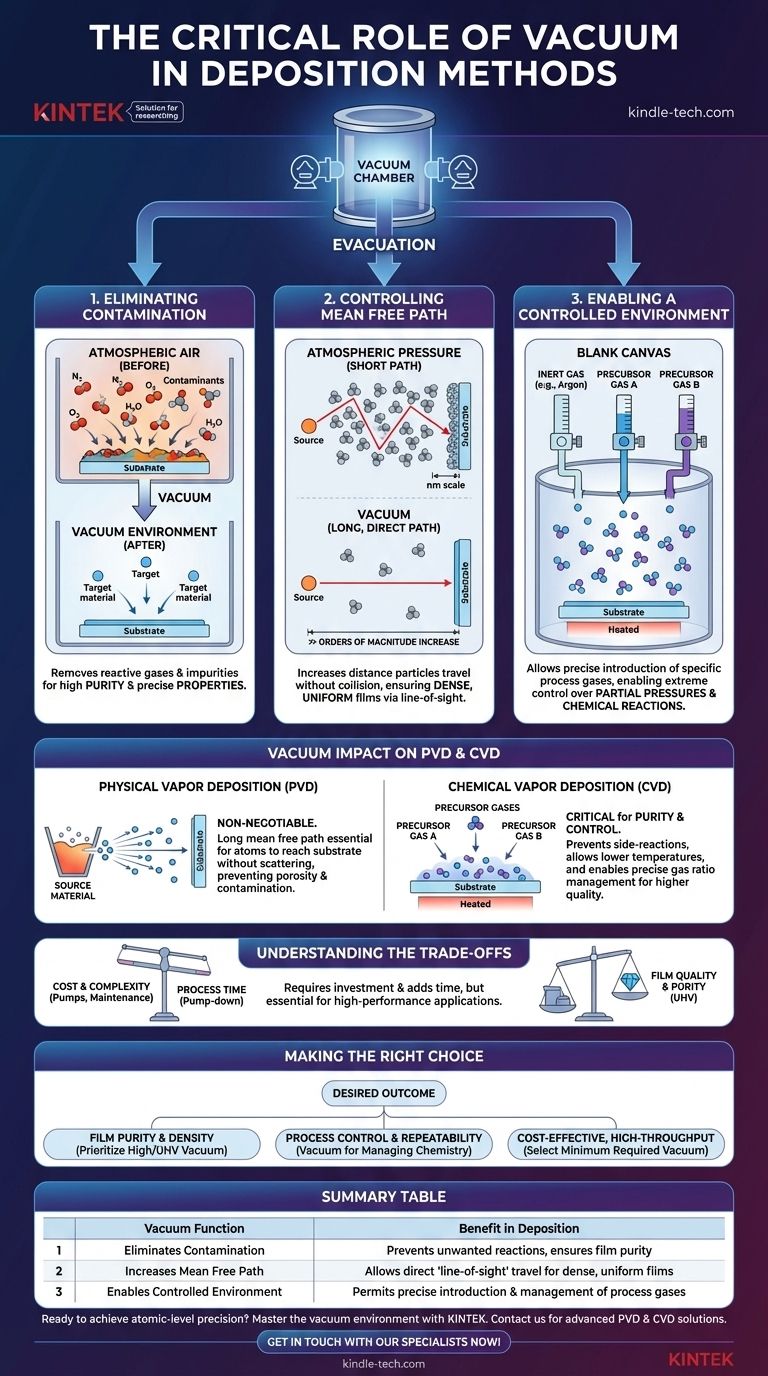

The Fundamental Purpose of Vacuum

A vacuum is the necessary starting point for nearly all high-quality thin-film deposition. It addresses several fundamental physics and chemistry challenges that would otherwise make the process unreliable or impossible.

Eliminating Contamination

Atmospheric air is a dense mixture of gases, primarily nitrogen and oxygen, along with water vapor and other trace elements. These are highly reactive contaminants.

If left in the chamber, these atmospheric molecules would bombard the substrate and react with the depositing material. This creates unwanted oxides and nitrides, compromising the purity and altering the intended electrical, optical, or mechanical properties of the film.

Controlling Mean Free Path

Mean free path is the average distance a particle can travel before colliding with another particle. At atmospheric pressure, this distance is incredibly short—on the nanometer scale.

In a vacuum, the particle density is drastically reduced, increasing the mean free path by many orders of magnitude. This allows atoms sputtered or evaporated from a source to travel in a straight, uninterrupted line to the substrate. This "line-of-sight" travel is critical for creating dense, uniform films.

Enabling a Controlled Process Environment

Once the unwanted atmospheric gases are removed, the chamber becomes a blank canvas. This allows for the precise introduction of specific process gases.

Whether it's a high-purity inert gas like Argon for a sputtering plasma or a mixture of precursor gases for Chemical Vapor Deposition (CVD), the vacuum ensures that the only molecules present are the ones you intentionally put there. This allows for extreme control over partial pressures and chemical reactions.

How Vacuum Impacts Deposition Processes

The principles of purity and control apply to all vacuum deposition methods, but their specific importance varies slightly between the two main categories: Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD).

In Physical Vapor Deposition (PVD)

PVD methods, such as sputtering and evaporation, involve physically ejecting or boiling atoms from a source material, which then travel to the substrate.

A vacuum is non-negotiable for PVD. The long mean free path is essential for source atoms to reach the substrate without being scattered by air molecules. Without it, the deposition rate would plummet, and the resulting film would be porous and heavily contaminated.

In Chemical Vapor Deposition (CVD)

CVD involves introducing precursor gases that react on a heated substrate to form the desired film. While some CVD processes can occur at atmospheric pressure (APCVD), high-performance applications rely on a vacuum.

In a vacuum-based CVD process, the primary benefit is purity and control. Removing air prevents unwanted side-reactions. It also allows for much lower process temperatures and precise control over the flow and ratio of precursor gases, leading to higher-quality, more uniform films.

Understanding the Trade-offs

While essential, implementing a vacuum system introduces its own set of engineering and economic challenges that represent a critical trade-off.

Cost and Complexity

Vacuum systems are complex and expensive. They require a series of pumps (roughing pumps and high-vacuum pumps), along with sophisticated gauges, valves, and seals. The maintenance of these systems is a significant operational cost.

Process Time (Throughput)

Evacuating a chamber to the desired pressure level, known as the pump-down time, is not instantaneous. This adds a significant amount of time to each deposition cycle, which can be a bottleneck in high-throughput manufacturing environments.

The Required "Level" of Vacuum

Not all processes require the same level of vacuum. A simple metallic coating via sputtering may only need a low or medium vacuum. In contrast, growing a perfect single-crystal semiconductor film for a high-end microprocessor requires an ultra-high vacuum (UHV) to achieve the necessary purity. The required vacuum level is always a trade-off between film quality, cost, and process time.

Making the Right Choice for Your Goal

The level of vacuum and the emphasis you place on it should be directly tied to the desired outcome of your film.

- If your primary focus is film purity and density: You must prioritize a high or ultra-high vacuum to minimize contamination from residual gases and maximize the mean free path.

- If your primary focus is process control and repeatability: The vacuum is your key tool for managing partial pressures and ensuring that the gas-phase chemistry is identical from one run to the next.

- If your primary focus is cost-effective, high-throughput coating: You should select the minimum level of vacuum that achieves the target film specifications to reduce pump-down time and equipment costs.

Ultimately, mastering the vacuum environment is mastering the art of creating materials with atomic-level precision.

Summary Table:

| Vacuum Function | Benefit in Deposition |

|---|---|

| Eliminates Contamination | Prevents unwanted reactions, ensures film purity |

| Increases Mean Free Path | Allows direct 'line-of-sight' travel for dense, uniform films |

| Enables Controlled Environment | Permits precise introduction and management of process gases |

Ready to achieve atomic-level precision in your lab?

Mastering the vacuum environment is key to creating high-purity, high-performance thin films. At KINTEK, we specialize in providing the advanced lab equipment and consumables you need for reliable Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) processes.

Our experts can help you select the right vacuum solutions to meet your specific goals for purity, control, and throughput. Contact us today to discuss your application and discover how KINTEK can enhance your laboratory's capabilities.

Get in touch with our specialists now!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production