The fundamental rule of brazing is to join two or more base metals by heating and melting a filler metal between them. Crucially, the temperature is kept high enough to melt the filler but always below the melting point of the base metals being joined. The molten filler is then drawn into the tight-fitting joint by capillary action, creating a strong metallurgical bond as it cools.

The core principle is not to fuse the parent materials together. Instead, brazing uses a filler metal as a powerful metallic "glue," which is pulled into a clean, narrow gap to form a bond that is often as strong as the base metals themselves.

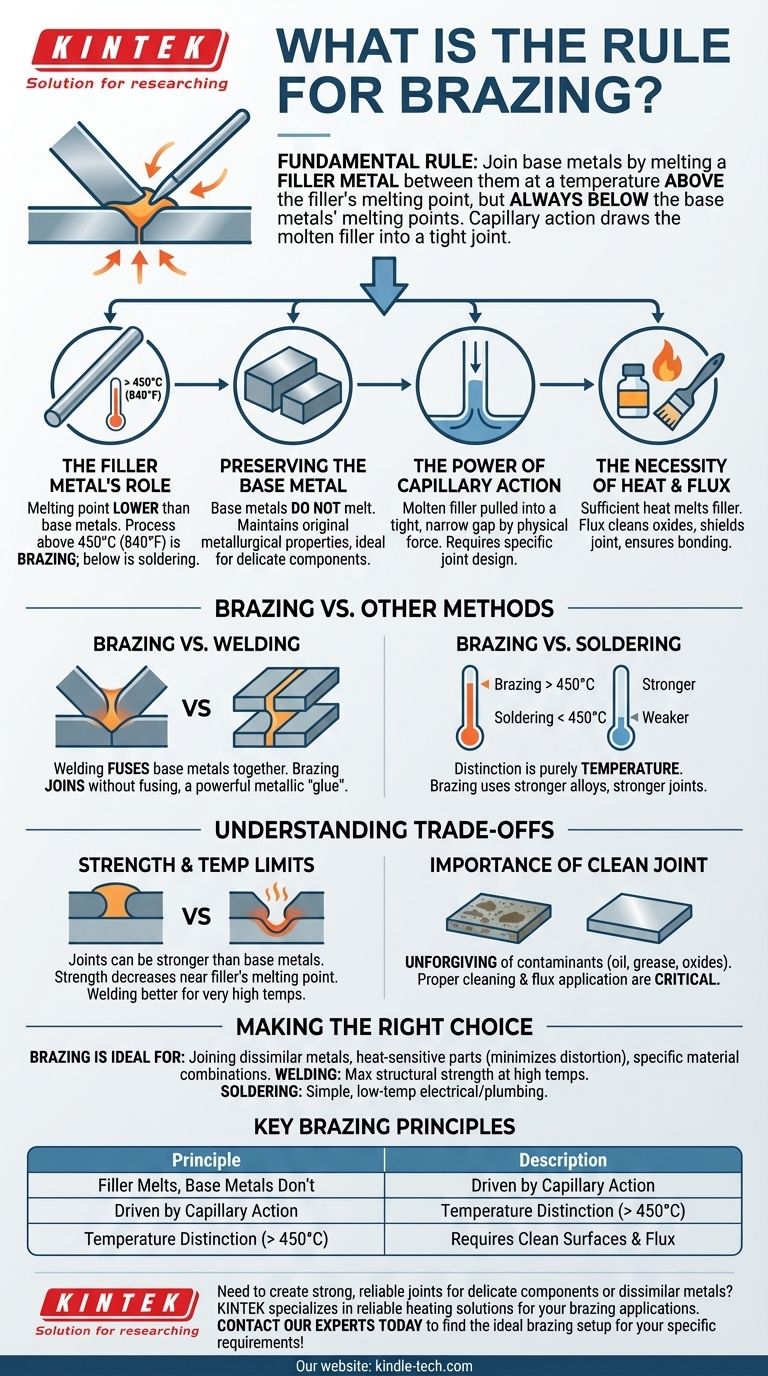

The Core Principles of a Successful Braze

To truly understand the rule of brazing, you must grasp the interaction of four key elements: the filler metal, the base metal, heat, and the concept of capillary action.

The Filler Metal's Role

The filler metal, or brazing alloy, is specifically chosen to have a melting point lower than the base metals.

The technical distinction between brazing and soldering is defined by temperature. If the filler metal melts above 450°C (840°F), the process is considered brazing. Below this temperature, it is defined as soldering.

Preserving the Base Metal

This is the most critical concept that separates brazing from welding. The base metals do not melt.

Because the parent materials remain solid, their original metallurgical properties are largely maintained. This makes brazing ideal for joining delicate or thin-walled components that would be distorted or destroyed by the high heat of welding.

The Power of Capillary Action

Brazing works because of a physical force called capillary action. This is the same force that draws water up into a paper towel.

When the filler metal becomes liquid, it is naturally pulled into the narrow, uniform gap between the two base metal pieces. For this to work effectively, the joint must be designed with a very specific, tight clearance.

The Necessity of Heat and Flux

Sufficient heat is required to melt the filler metal and allow it to flow. This heat is applied broadly to the joint area, not concentrated in one spot like in welding.

The metal surfaces must be perfectly clean for a bond to form. A chemical agent called flux is applied before heating. The flux melts, cleans away oxides from the base metal, and shields the joint from oxygen during heating, allowing the filler to bond directly to the parent material.

Brazing vs. Other Joining Methods

Understanding the central rule of brazing becomes clearest when comparing it to other common methods.

Brazing vs. Welding

Welding fuses base metals together. It works by melting the edges of the parent materials, often along with a filler metal, to form a single, homogenous piece of metal upon cooling.

Brazing joins base metals without fusing them. It is a bonding process that leaves the parent materials intact.

Brazing vs. Soldering

The distinction here is purely based on temperature. Both processes follow the same principle of melting a filler metal that is drawn into a joint by capillary action.

However, the higher temperatures used in brazing employ stronger filler alloys, resulting in a joint that is significantly stronger than a soldered one.

Understanding the Trade-offs

While powerful, brazing is not the solution for every application. Understanding its limitations is key to using it correctly.

Strength and Temperature Limits

A properly brazed joint can be stronger than the base metals themselves. However, the joint's strength rapidly decreases as the service temperature approaches the filler metal's melting point.

Welded joints are superior for applications requiring high strength at very high temperatures.

The Importance of a Clean Joint

Brazing is unforgiving of contaminants. Any oil, grease, or oxides on the surface of the base metals will prevent the capillary action and stop the filler metal from wetting and bonding to the surfaces.

Proper cleaning and preparation of the joint are absolutely critical for a successful braze.

Making the Right Choice for Your Application

Applying the rule of brazing effectively means choosing it for the right reasons.

- If your primary focus is joining dissimilar metals or heat-sensitive parts: Brazing is often superior because its lower, more diffuse heat input prevents distortion and can join materials that cannot be welded together.

- If your primary focus is maximum structural strength at high temperatures: Welding is the appropriate choice, as it directly fuses the base metals into a single piece.

- If your primary focus is a simple, low-temperature electrical or plumbing connection: Soldering is the easier and more economical method.

Ultimately, remembering that the goal is to melt the filler and not the base metal is the key to correctly applying brazing to create exceptionally strong and clean joints.

Summary Table:

| Key Brazing Principle | Description |

|---|---|

| Filler Metal Melts, Base Metals Don't | The fundamental rule: heat is controlled to melt the filler alloy but not the parent materials. |

| Driven by Capillary Action | Molten filler is drawn into a tight joint gap, creating a strong metallurgical bond. |

| Temperature Distinction | Brazing uses filler metals that melt above 450°C (840°F); below this is soldering. |

| Requires Clean Surfaces & Flux | Proper cleaning and flux application are critical to prevent oxides and ensure a successful bond. |

Need to create strong, reliable joints for delicate components or dissimilar metals?

The precise temperature control required for successful brazing depends on high-quality equipment. KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable heating solutions perfect for your brazing applications.

Contact our experts today to find the ideal brazing setup for your specific materials and requirements!

Visual Guide

Related Products

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Large Vertical Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Muffle Furnace Oven for Laboratory

People Also Ask

- Why is graphite resistant to heat? Unlocking Its Exceptional Thermal Stability

- Why does graphite have a high melting point? The Power of Its Giant Covalent Structure

- Is high ash content good? A Guide to Understanding Pet Food Mineral Levels

- What is the thermal property of graphite? Mastering Extreme Heat Management

- What role does a laboratory high-temperature furnace play in the pre-recrystallization heat treatment (PHT) of arc-sprayed coatings?