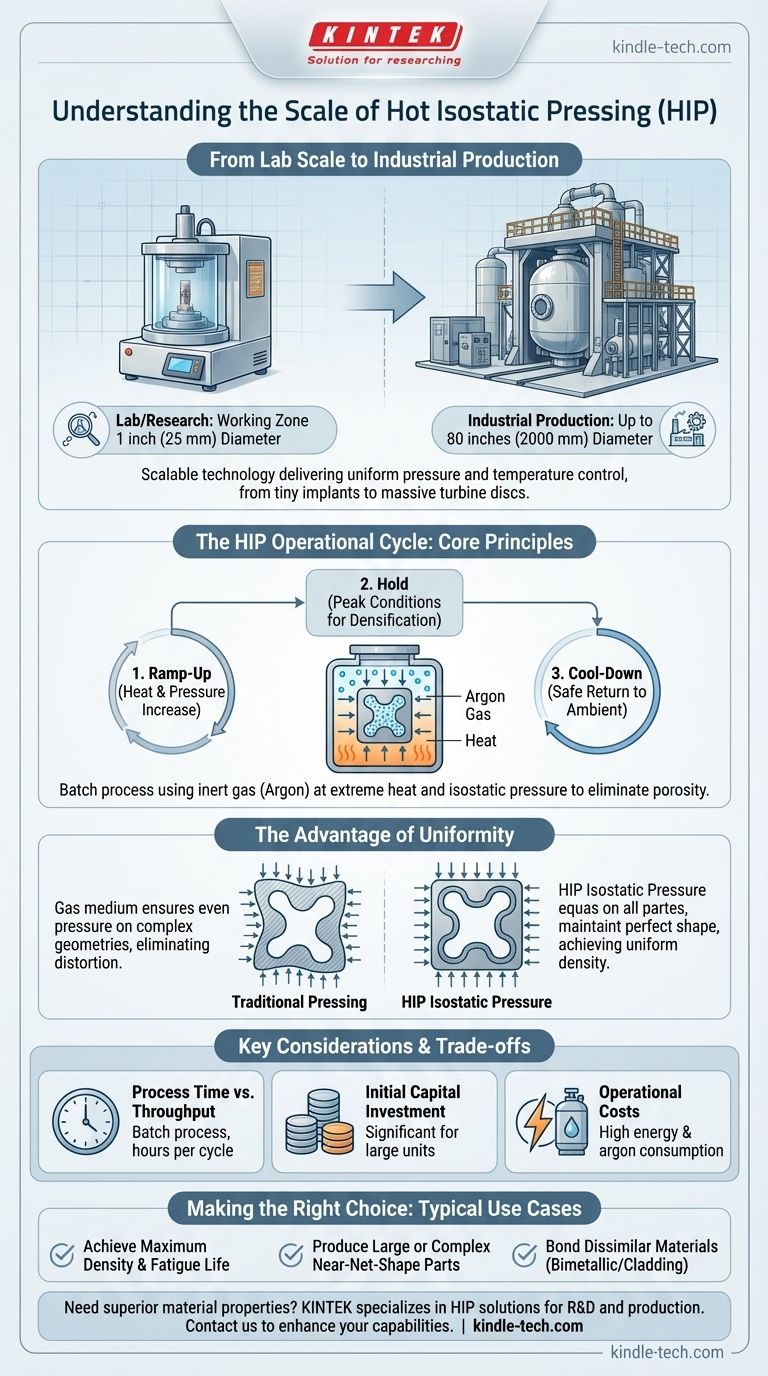

At its core, hot isostatic pressing (HIP) is a highly scalable manufacturing process. Equipment ranges from small laboratory-scale units with working zones as small as one inch (25 mm) in diameter to massive industrial systems over 80 inches (2000 mm) in diameter, capable of processing very large components or high volumes of smaller parts in a single cycle.

While the physical scale of HIP equipment is impressive, its true value lies in its ability to deliver uniform pressure and temperature control regardless of size. This ensures that every part, from a tiny medical implant to a massive turbine disc, achieves maximum theoretical density and superior mechanical properties.

The HIP Process: A Look Inside the Vessel

To understand the scale of HIP, you must first understand its operational principles. The process is not continuous but operates in distinct, computer-controlled batches.

The Core Principle: Heat and Uniform Pressure

HIP places components inside a sealed pressure vessel. The chamber is then filled with an inert gas, typically argon, which is heated and pressurized to extreme levels.

This combination of high heat and uniform, isostatic (equal in all directions) pressure consolidates materials on a microscopic level.

The Operational Cycle

A typical HIP cycle involves three phases:

- Ramp-Up: The temperature and pressure are gradually increased according to a pre-programmed profile specific to the material and part.

- Hold: The parts are held at peak temperature and pressure for a specified duration to allow for full densification or bonding.

- Cool-Down: The system safely returns to ambient temperature and pressure.

The Role of Precision Control

Modern HIP systems are computer-controlled, allowing for highly repeatable and precise cycles. This ensures that whether you are processing a single large part or thousands of small ones, the results are consistent and meet exact product requirements.

From Lab Scale to Industrial Production

The scalability of HIP is what makes it suitable for a wide range of applications, from research and development to full-scale manufacturing.

Equipment Dimensions

The working zone of HIP systems can be as small as 1 inch in diameter for research or as large as 80 inches (2 meters) in diameter for industrial production. This allows the technology to handle everything from small, intricate components to single-piece parts weighing several tons.

Material Requirements at Any Scale

Regardless of the size of the machine, the input material must be suitable for the process. When working with powders, they must be free-flowing and easily compacted. The process is renowned for producing products with higher density at lower temperatures compared to traditional hot pressing.

The Advantage of Uniformity

The use of a gas as the pressure medium is critical. It ensures that even parts with highly complex geometries receive perfectly uniform pressure on all surfaces. This eliminates distortion and ensures consistent densification throughout the entire component, a benefit that scales perfectly from the smallest to the largest parts.

Understanding the Trade-offs

While powerful, HIP technology comes with specific considerations that are important for evaluating its fit for your application.

Process Time vs. Throughput

The complete HIP cycle—including heating, holding, and cooling—can take several hours. This makes it a batch process, which can be a limitation for applications requiring extremely high, continuous throughput.

Initial Capital Investment

Hot isostatic pressing systems are sophisticated high-pressure, high-temperature vessels. The initial capital expenditure for this equipment can be significant, especially for larger-scale industrial units.

Operational Costs

The process consumes considerable energy to achieve the required temperatures and pressures. Furthermore, the use of high-purity inert gas like argon adds to the operational cost of each cycle.

Making the Right Choice for Your Goal

Selecting HIP depends entirely on your end goal. The process excels where material integrity is the highest priority.

- If your primary focus is achieving maximum density and removing all internal porosity: HIP is the definitive choice for creating components with superior fatigue life and mechanical strength.

- If your primary focus is producing very large or complex near-net-shape parts: The availability of large-scale HIP systems makes it a leading technology for aerospace, energy, and defense applications.

- If your primary focus is bonding dissimilar materials with a perfect metallurgical bond: HIP provides an unmatched ability to create bimetallic or cladded components with a bond that is as strong as the parent materials.

Ultimately, hot isostatic pressing is a key enabling technology that delivers unparalleled material quality across an exceptionally wide range of scales.

Summary Table:

| HIP Scale | Working Zone Diameter | Typical Use Case |

|---|---|---|

| Lab/Research | 1 inch (25 mm) | R&D, small components |

| Industrial Production | Up to 80 inches (2000 mm) | Large parts, high-volume batches |

Need to achieve maximum density and superior mechanical properties for your components? KINTEK specializes in lab equipment and consumables, including solutions for advanced processes like hot isostatic pressing. Whether you're in R&D or large-scale production, we provide the technology to ensure uniform results. Contact us today to discuss how our HIP expertise can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Heat Press Machine

People Also Ask

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance